Method for elimination ions in system of TiO2 hydrate granules in nano level and water

A hydrate and nano-scale technology, applied in the field of membrane separation, can solve problems such as the inability to remove inorganic ions, and achieve excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

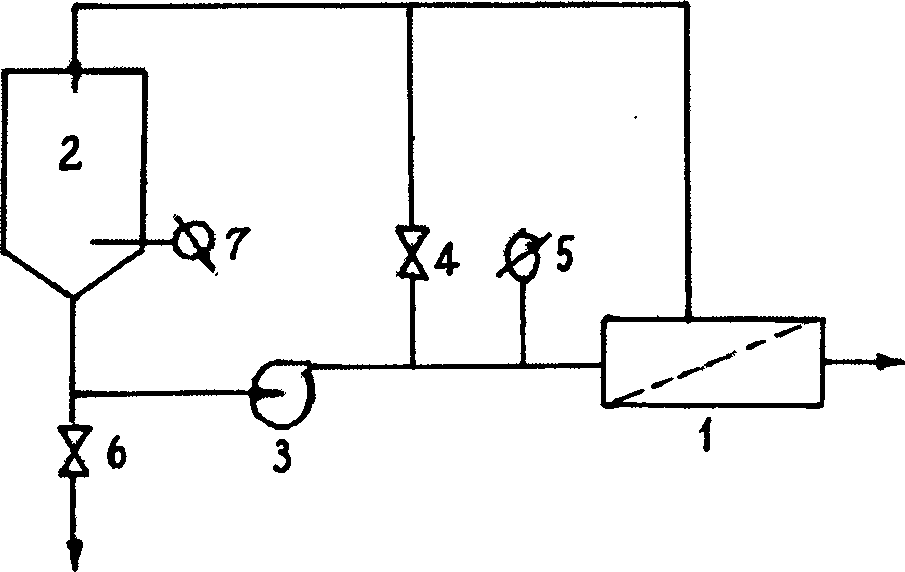

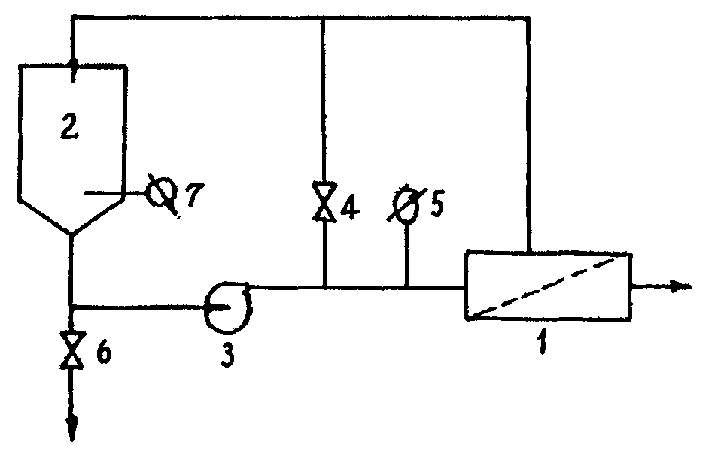

[0022] see figure 1 , using a polyethersulfone (PES) ultrafiltration flat membrane device 1 with a molecular weight cut-off of 50K, for nano-TiO 2 Hydrated material liquid (Cl - The concentration is 2.51×10 -3 mol / L) for concentration and desalination. The feed liquid is poured into the feed tank 2, the high-pressure pump 3 is started, the bypass valve 4 is opened, the operating pressure (based on the reading of the pressure gauge 5) is adjusted to 0.49MPa, the amount of feed liquid added is 2.5L, and the experiment is carried out according to the above steps. When the feed solution is concentrated to 0.5L, add 0.6L deionized water to carry out dilution and wash, and the wash multiple is 1.2. When the volume of the feed liquid is concentrated to 0.5L again, add 0.6L deionized water to dilute and wash. After several washes, the Cl of the concentrated solution - The concentration is 7.98×10 -5 mol / L, the average membrane flux is maintained at 90L / m 2 .h and above. During ...

Embodiment 2

[0024] Using polysulfone (PS) ultrafiltration flat membrane equipment with a molecular weight cut-off of 20K, the 2 Hydrated material liquid (Cl - Concentration is 0.5mol / L) to concentrate and desalt. The operating pressure is 0.25MPa, the amount of feed liquid added is 2.0L, and the experiment is carried out according to the above steps. When the feed liquid is concentrated to 0.5L, add deionized water for dilution and top washing, and the jacket water multiple is 1.0. After several washes, the Cl of the concentrate - The concentration is 4.24×10 -5 mol / L, the average membrane flux is maintained at 115L / m 2 .h and above. During the experiment, samples were taken every 3 minutes for testing.

Embodiment 3

[0026] Using polysulfone (PS) ultrafiltration flat membrane equipment with a molecular weight cut-off of 20K, the 2 Hydrated material liquid (Cl - Concentration is 0.5mol / L) to concentrate and desalt. The operating pressure is 0.4MPa, the amount of feed liquid added is 2.0L, and the experiment is carried out according to the above steps. When the feed liquid is concentrated to 0.16L, add deionized water for dilution and top washing, and the jacket water multiple is 1.5. After several washes, the Cl of the concentrate - The concentration is 6.12×10 -5 mol / L, the average membrane flux is maintained at 80L / m 2 .h and above. During the experiment, samples were taken every 5 minutes for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com