Manufacture of low polarization mode dispersion single mode optical fibers and products thereby

A manufacturing method and modal dispersion technology, applied in glass manufacturing equipment, manufacturing tools, glass fiber products, etc., can solve the problems of increasing optical fiber resistance, weakening the torque generated by the twisting system, increasing the difficulty of equipment maintenance, and achieving good friction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

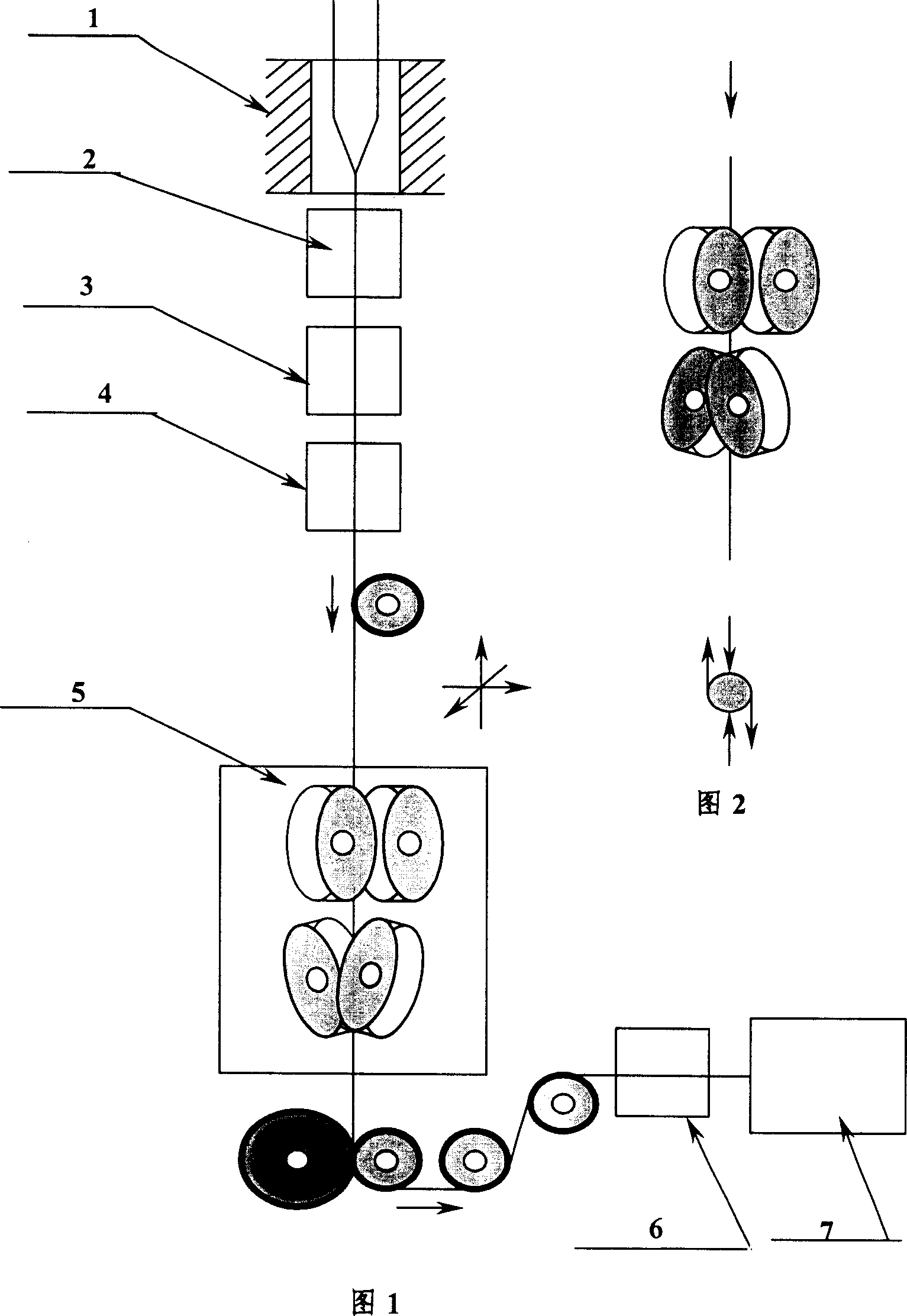

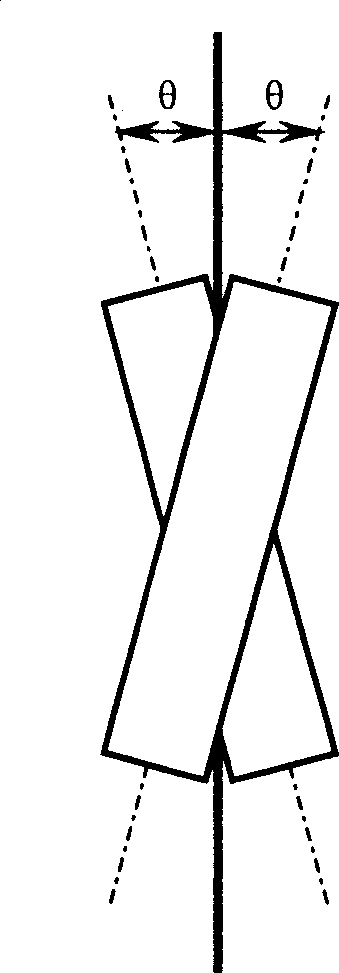

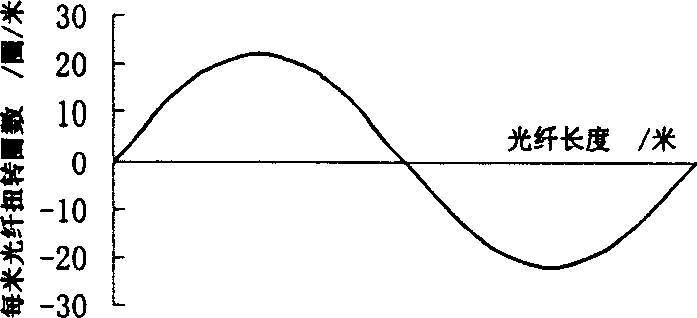

[0102] In this example, the single-mode optical fiber with low polarization dispersion is prepared by the following method: a φ80 optical fiber preform using the sleeve process is fixed to the rod feeding mechanism at the top of the drawing tower, and sent to a resistance furnace with a temperature of 2200 ° C for 1000 m / min speed for wire drawing, the drawn optical fiber passes through the bare optical fiber geometric size monitor, coating system, rubbing system, drawing tension wheel, finished optical fiber geometric size monitor and wire receiving system in sequence, and the optical fiber introduces torque in the rubbing system The optical fiber is forced to rotate around its axis, and the direction of rotation of the optical fiber changes periodically with the reciprocating swing of the rubbing wheel in a plane parallel to the optical fiber, and a unique mechanical wave is formed, which can be drawn upstream along the optical fiber Direction propagation, and can reach the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap