Method and device for treating surfaces of metallic strip, especially for pickling rolled material

A technology for metal strips and equipment, which is applied to the surface of metal strips, especially in the field of pickling and rolling materials and equipment, can solve the problem of no regulation of guiding pickling medium, etc., and achieve the effect of reducing the burden and improving the relative speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

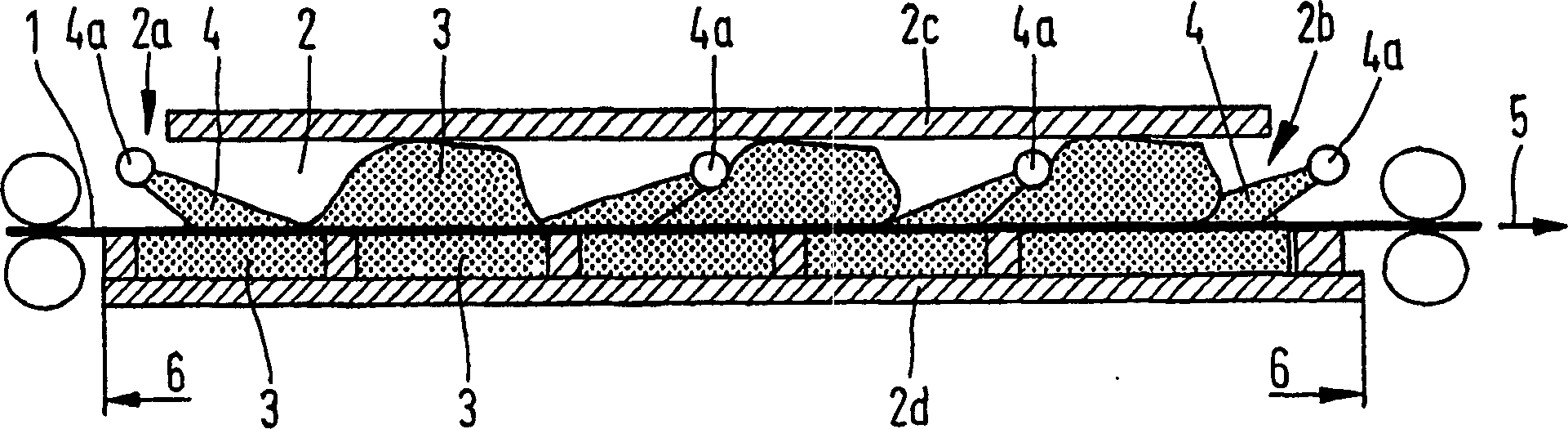

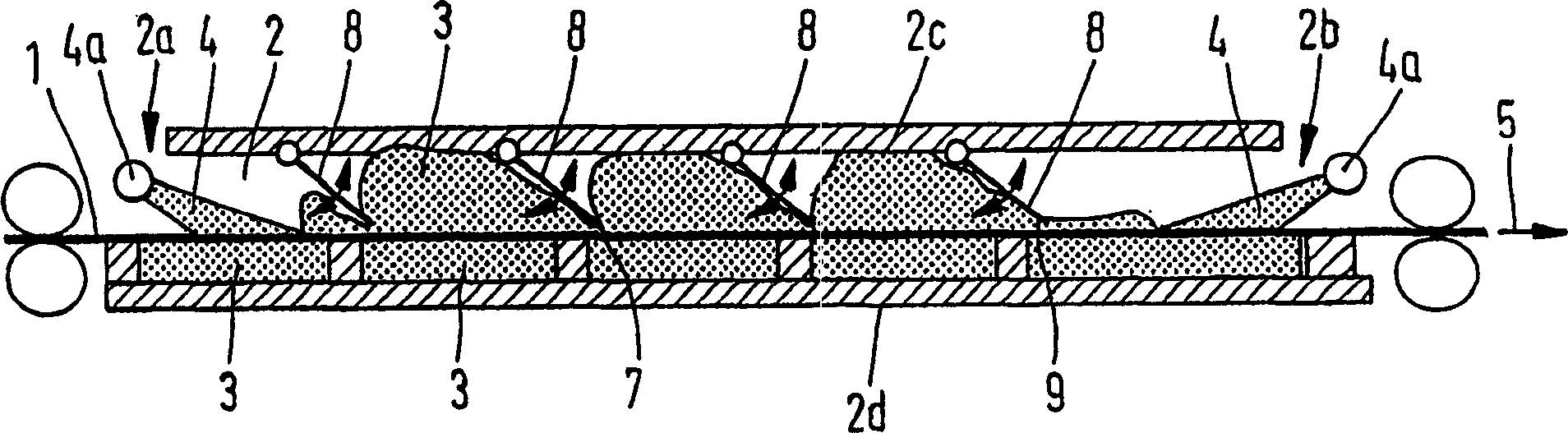

[0030] A device for treating the surface of metal strip 1 and in particular pickled rolling stock is shown by a pickling tunnel in the pickling tank. The strip 1 is guided through the processing tunnel 2 by means of pairs of conveyor rollers arranged at the tunnel inlet 2a and at the tunnel outlet 2b. In this case, the strip 1 is rinsed by jets of acid-containing descaling pickling medium 3 , which streams are sprayed from a plurality of beams with nozzle rows 4 a. The jet 4 is adjusted at the channel inlet 2 a in the strip conveying direction 5 and at the channel outlet 2 b against the strip conveying direction 5 in order to prevent the pickling medium 3 from rapidly flowing away.

[0031] according to figure 1 , in the conveying channel section 6, a jet 4 and a nozzle row 4a oriented opposite to the strip conveying direction 5 are arranged starting from the channel outlet 2b.

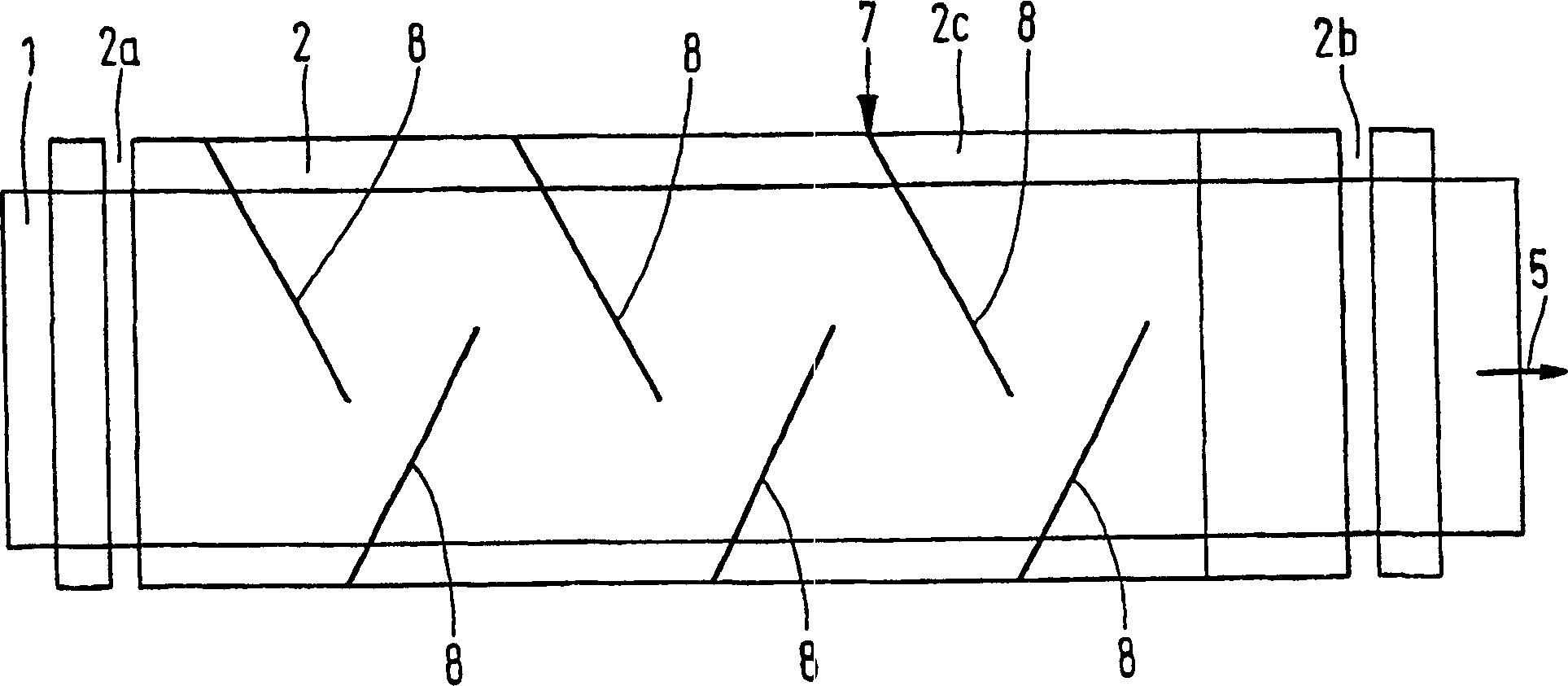

[0032] according to figure 2 The deflection element 8, which prevents the pickling medium 3 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com