Polythene valve port bag and mfg method thereof

The technology of a polyethylene valve and a manufacturing method, which is applied to the manufacturing field of polyethylene valve pockets, can solve the problems of easy liquefaction at the sticking place, easy hardening at the sticking place, moisture in the package, etc., and achieves good firmness, firm welding, and convenient sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

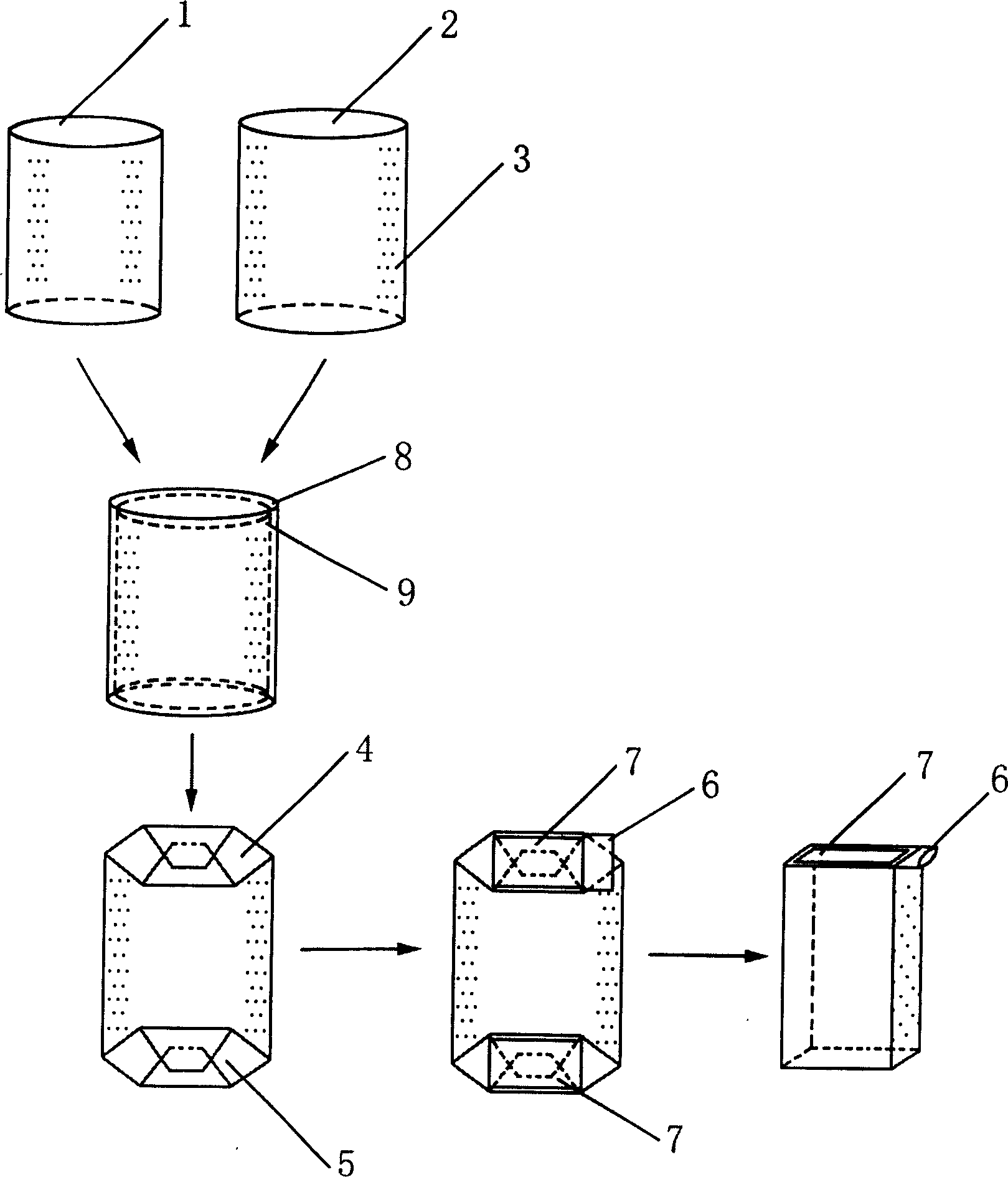

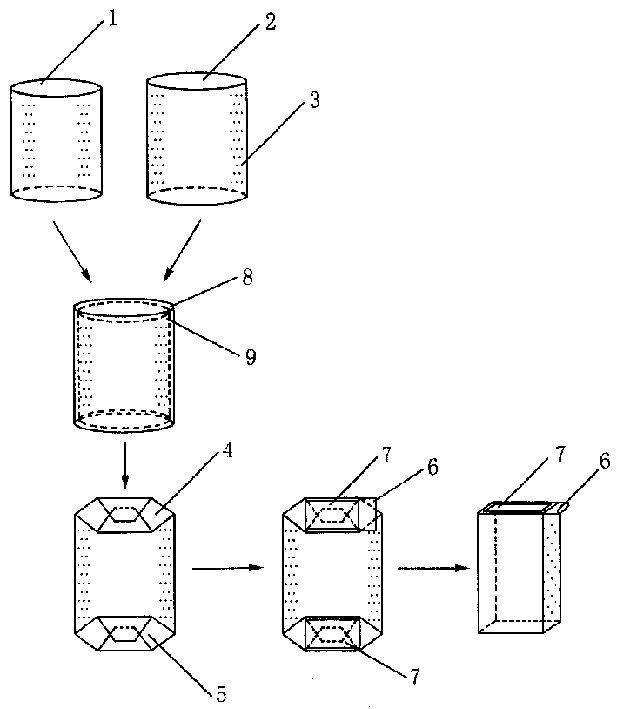

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0009] Cut the inner and outer polyethylene cylinder materials 1 and 2 into the length required by the valve pocket, and puncture multiple rows of pinholes 3 evenly and longitudinally on the inner and outer cylinder materials 1 and 2 respectively, and cut the inner and outer polyethylene cylinder materials 1 and 2 with pinholes 3 2 phase sets, so that the pinholes 3 on the inner and outer cylinder materials 1 and 2 are not in the same position, the inner ring 8 of the outer cylinder material at both ends and the outer ring 9 of the inner cylinder material are welded at high temperature respectively, and the two ends of the double-layer cylinder material are long and round The openings are respectively folded into multi-edge geometric upper and lower bottoms 4 and 5 with overlapping layers of base materials, and a layer of fabric 7 with the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com