Blower and air conditioner with the same

An air conditioner and blower technology, applied in the fields of blowers and air conditioners, can solve the problems of reducing air supply efficiency, deteriorating aerodynamic characteristics of blades 23, increasing electric power consumption of motor 24, etc., so as to suppress the reduction of static pressure characteristics, Improved aerodynamics and reduced electric power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, refer to Figure 1 ~ Figure 1 3 and Figure 14 ~ Figure 16 Explain the implementation form of the present invention, in Figure 1 ~ Figure 1 In 3, the same parts are marked with the same reference symbols.

[0039] The first implementation form

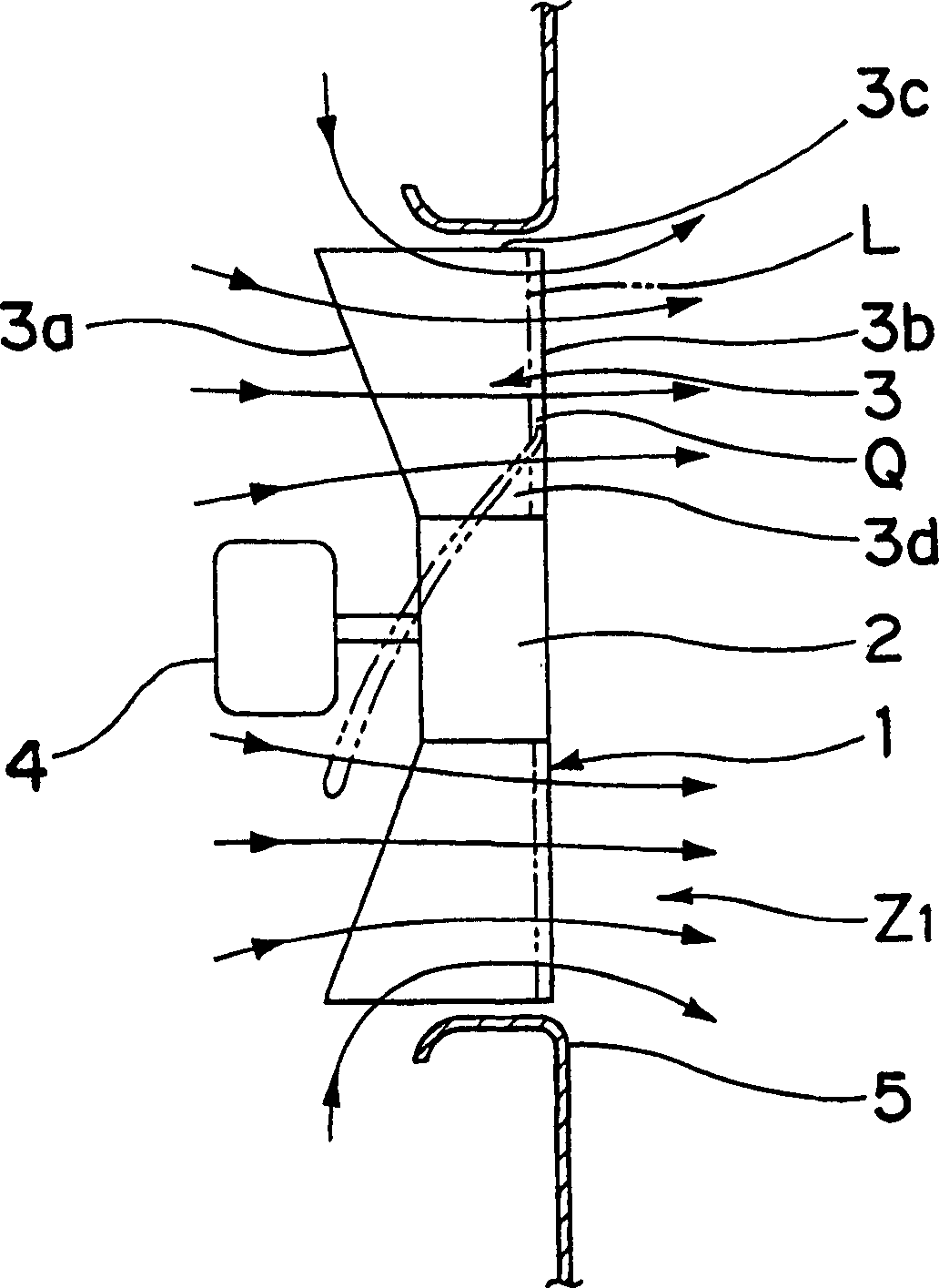

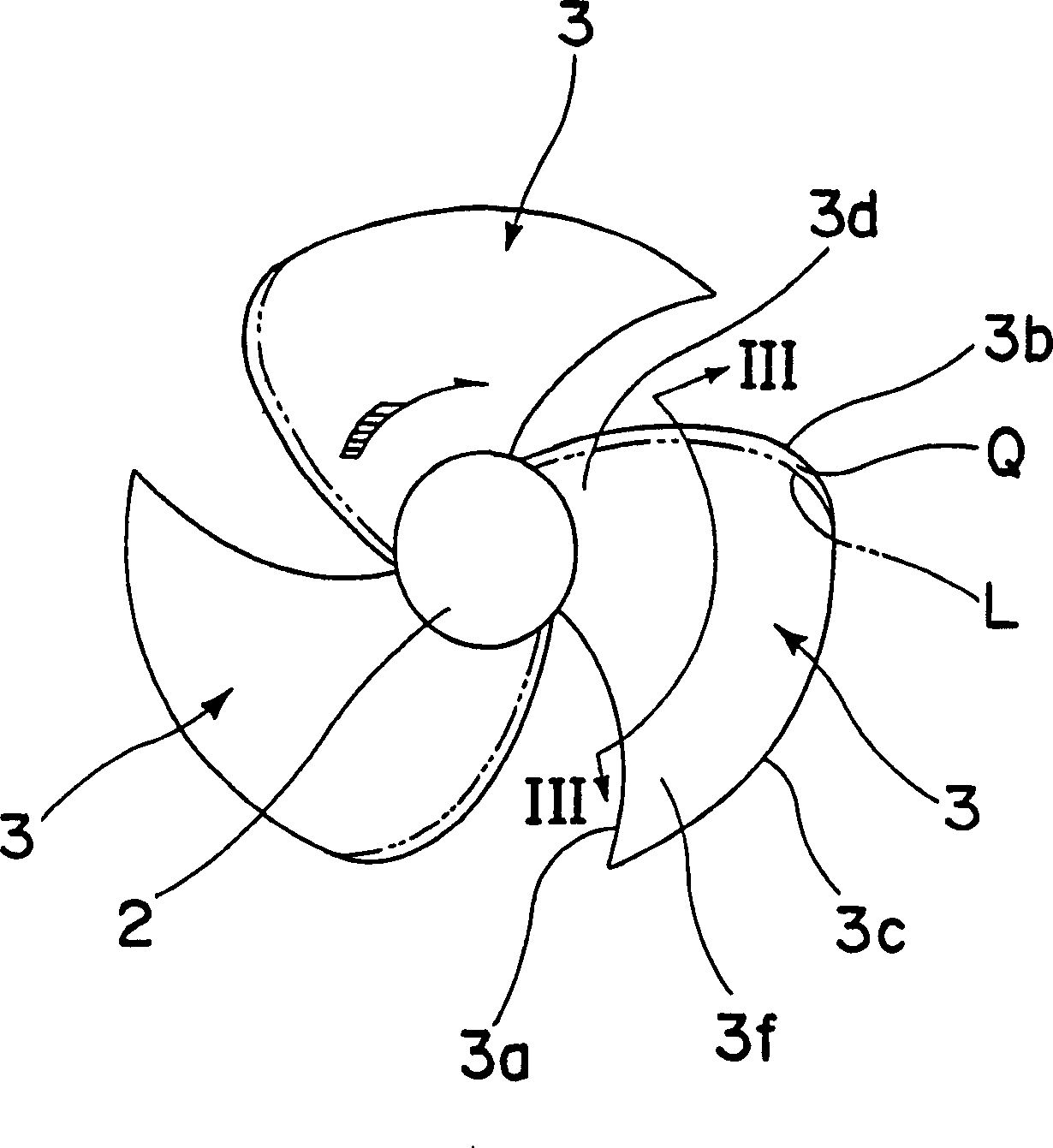

[0040] figure 1 , Shows the axial flow fan Z of the first embodiment of the present invention 1 . The axial blower Z 1 It is a so-called "propeller blower", which adopts a structure in which a plurality of (three in this embodiment) blades 3, 3, 3 are installed radially on the outer periphery of the hub 2 at a given installation angle. 1. It is driven by the motor 4 to rotate, and at the same time, on the outer peripheral side of the impeller 1, a bell cover 5 is arranged around the impeller.

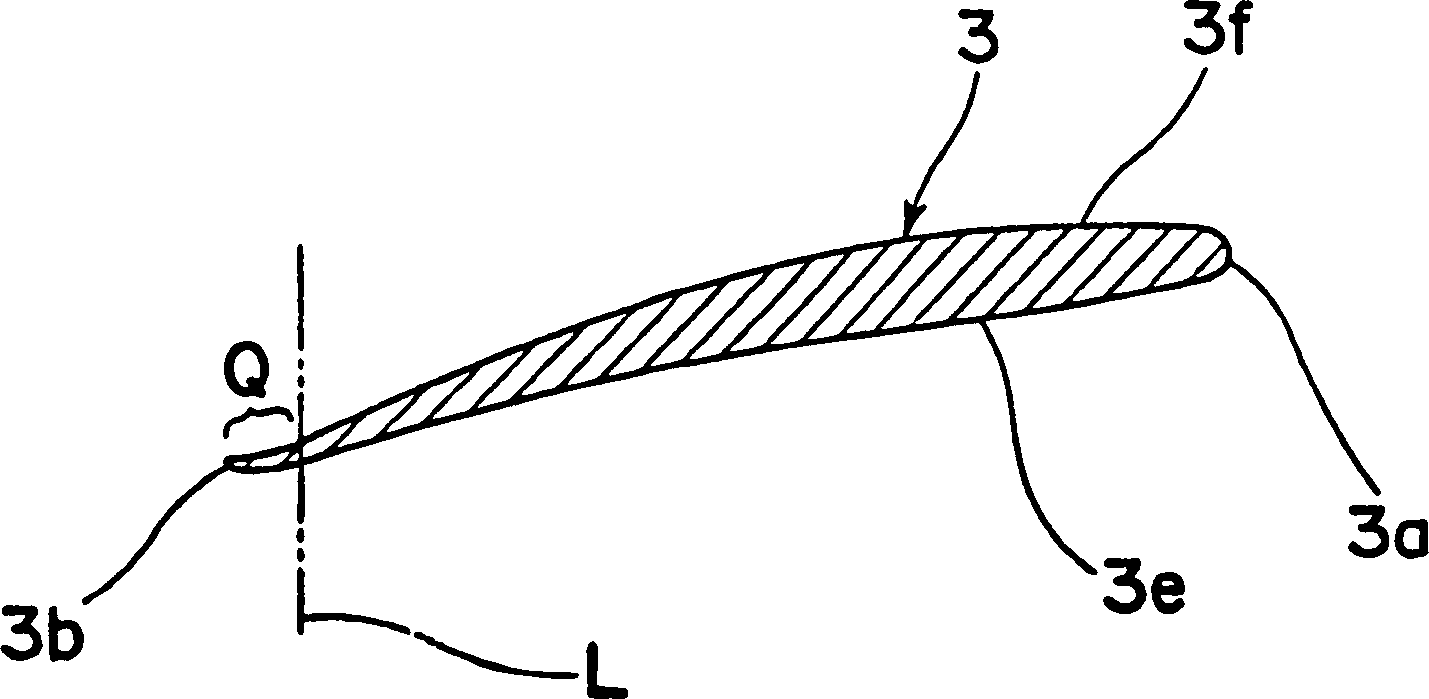

[0041] Such as figure 2 and image 3 As shown, the blade 3 of the impeller 1 is a forward-curved blade whose front edge 3a extends forward in the direction of rotation. At the same time, it has a relatively thick blade thickness an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com