Sealed zipper

A technology for sealing zippers and zippers, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of incomplete guarantee, long service time, etc., and achieve the effect of reducing sealing quality, reducing resistance, and weakening sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

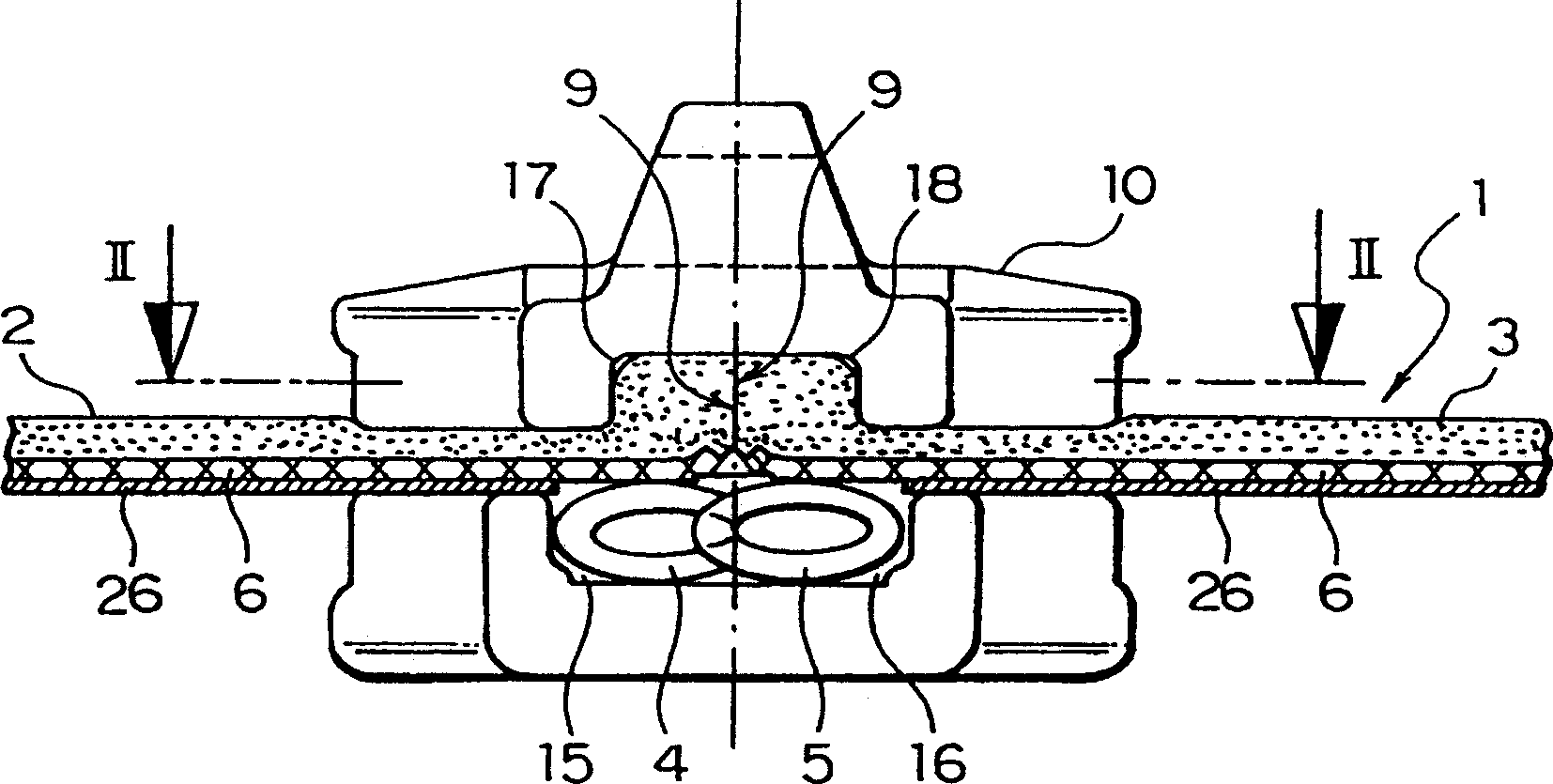

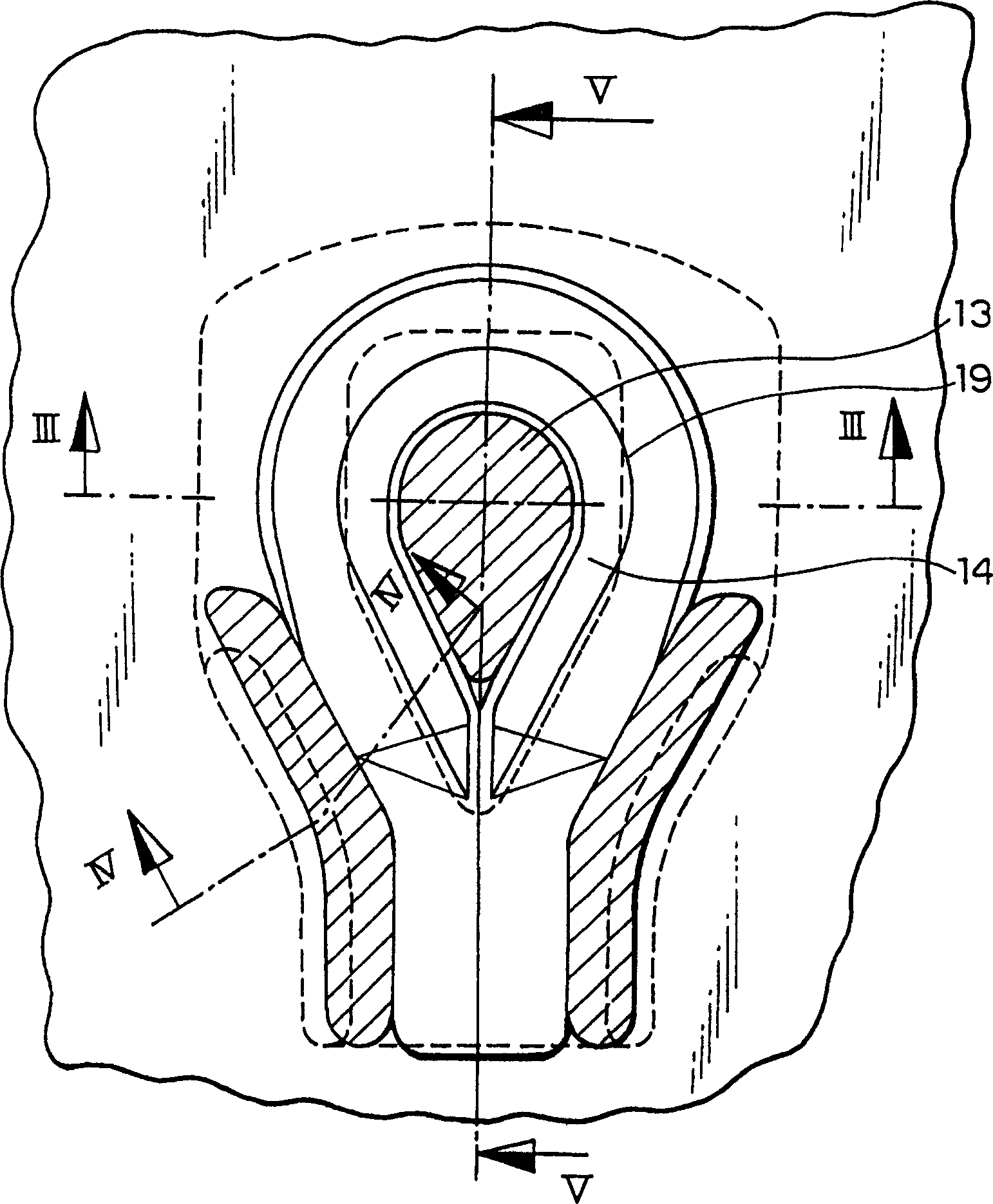

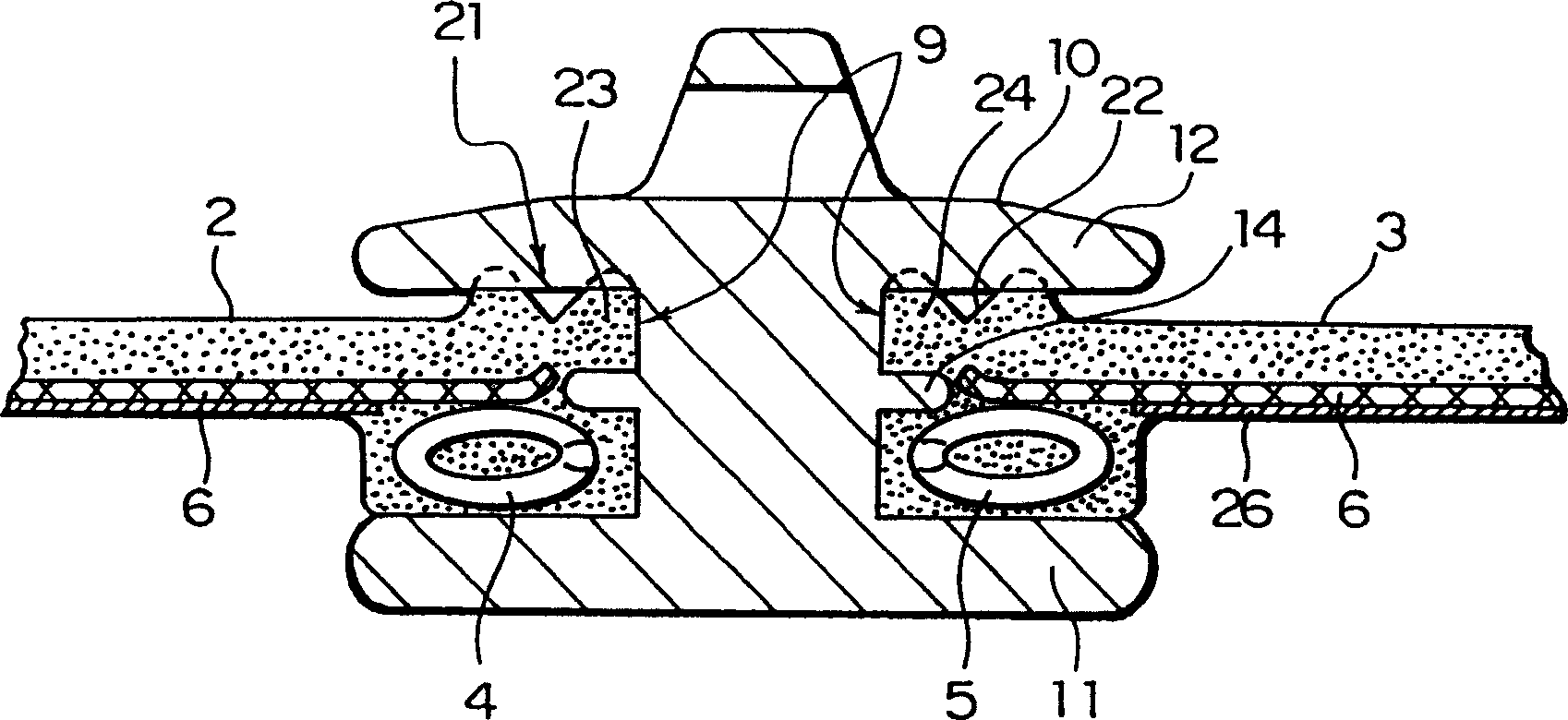

[0018] In the conventional method, the zipper 1 shown in the drawings has two zipper support strips 2, 3 to which the coupler rows 4, 5 are sewn. The support strips 2 , 3 each comprise a textile base strip 6 , for example formed of a polymer or some other plastic. However, it is also possible for the base strip 6 to be formed from cotton threads.

[0019] Each base strip 6 has a soft elastomer covering on the side facing away from the coupler rows 4,5. However, this term includes elastomers, while thermoplastics can also be used to coat the base strip 6 .

[0020] The overlay cannot be seen in the attached drawings. Details regarding the soft cover layer and its position relative to the end surface of the base strip 6, which completely covers the base strip, can be seen from the applicant's earlier filed application 19924539.8-26. These and other purposes of the earlier filed application are to sew the continuous row of coupling elements 4,5 to the zipper support strips 2,3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com