Device for industrial production of biomaggot

A production device and factory-like technology, applied in animal husbandry and other directions, can solve the problems of difficult separation of maggots, low production efficiency, low production automation, etc., to reduce pollution, improve automation and production efficiency, and factory-based efficient production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

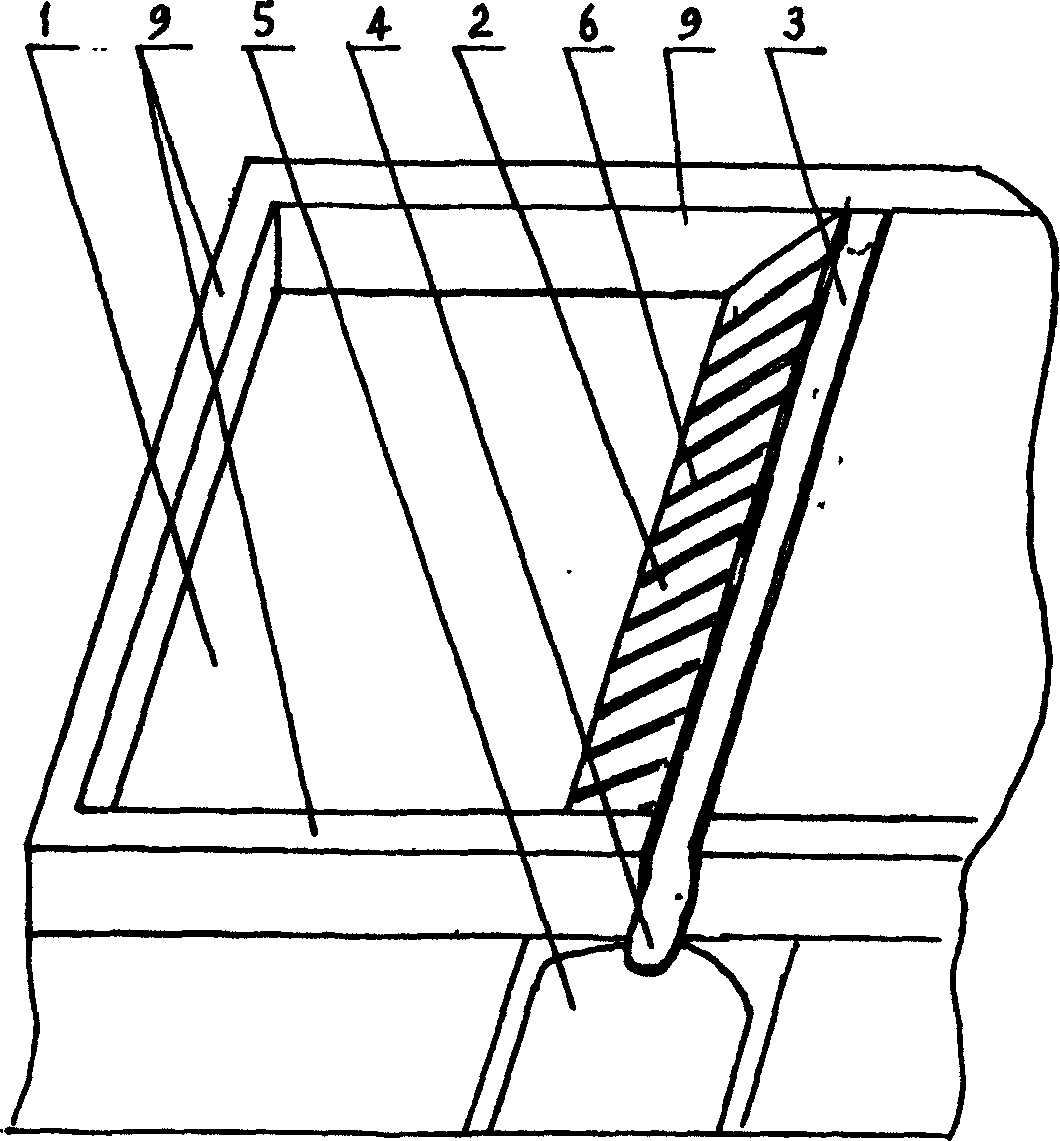

[0017] Embodiment 1: as figure 1 As shown, the biological maggot industrial production device is provided with a pond 1, which can be a rectangular cement plane (250cm × 400cm at the bottom of the pond), and a slope 2 is arranged around the pond, and the top of the slope and the base of the U-shaped guide ditch 3 Connected, the end 4 of the guide groove is located above the collection chamber 5 . The slope body 2 is provided with parallel V-shaped grooves 6 from the bottom of the pool to the top of the slope body, and the end of the grooves 6 is just the top of the guide groove 3 . When collecting the biological maggots, the container (such as a barrel) can be placed in the collection chamber, allowing the biological maggots to directly drop into the container from the end 4 of the guide ditch. The other 3 sides of pond 1 are the vertical body of wall 9 that height is 12~15cm, to prevent biological maggot from escaping from inside and outside the pond.

Embodiment 2

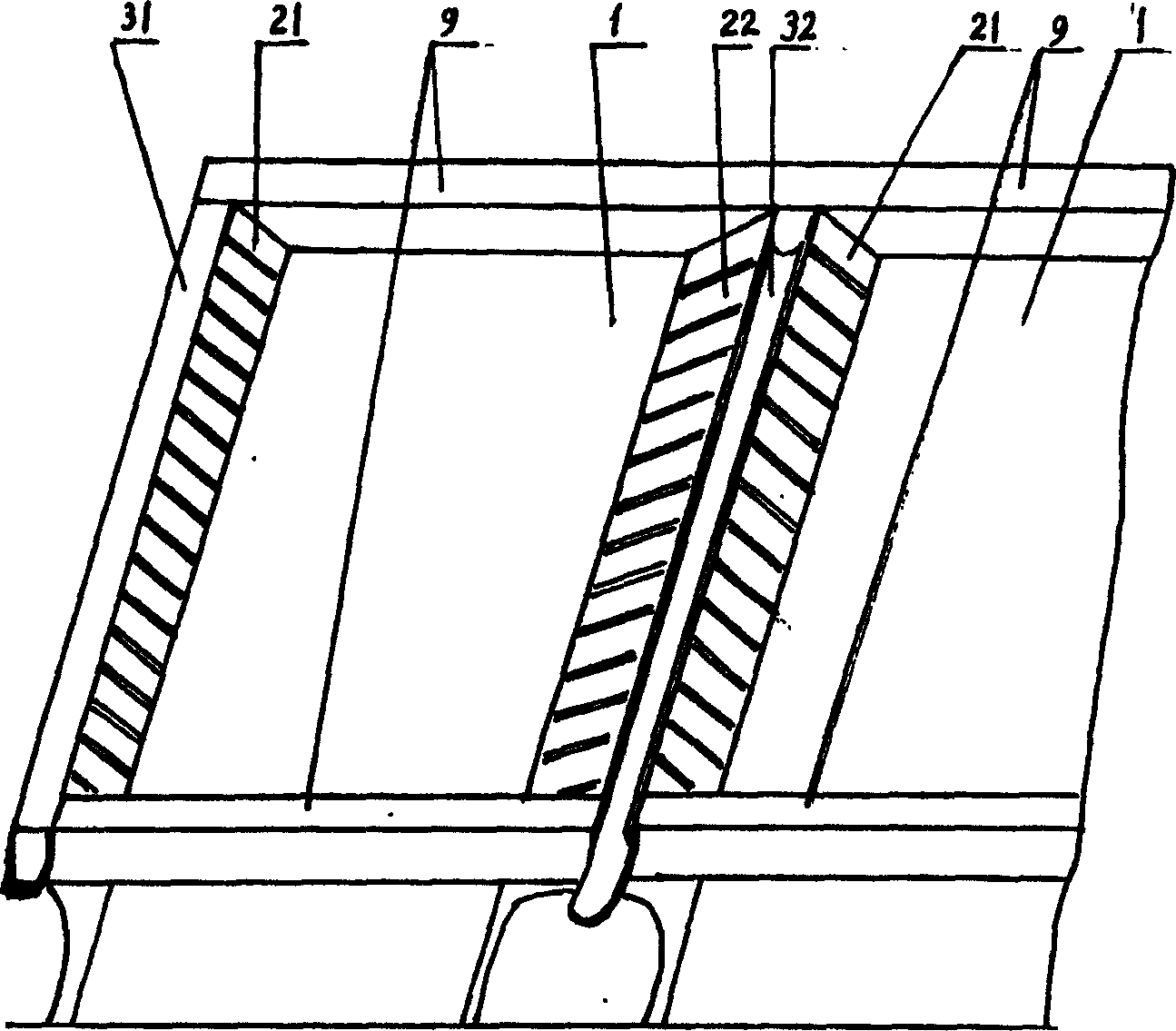

[0018] Embodiment 2: as figure 2 Shown, be made as single-layer two-way type, cultivate pond 1 and establish a plurality of, establish slope body 21,22 at 2 opposite sides of pond, be provided with guide ditch 31,32 etc. correspondingly. The other 2 sides of Yuchi 1 are vertical walls 9.

[0019] The maggot material separation device can also be designed as a double-layer or multi-layer structure. At the end of the guide groove, the upper opening of the collection chamber can be provided with a cover, which is not shown in the figure and is mainly used for shading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com