Automatic plum pressing machine

A baggage press, automatic technology, applied in the fields of application, food science, food processing, etc., can solve the problem of frequent manual operation, and achieve the effect of reducing manual operation steps and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

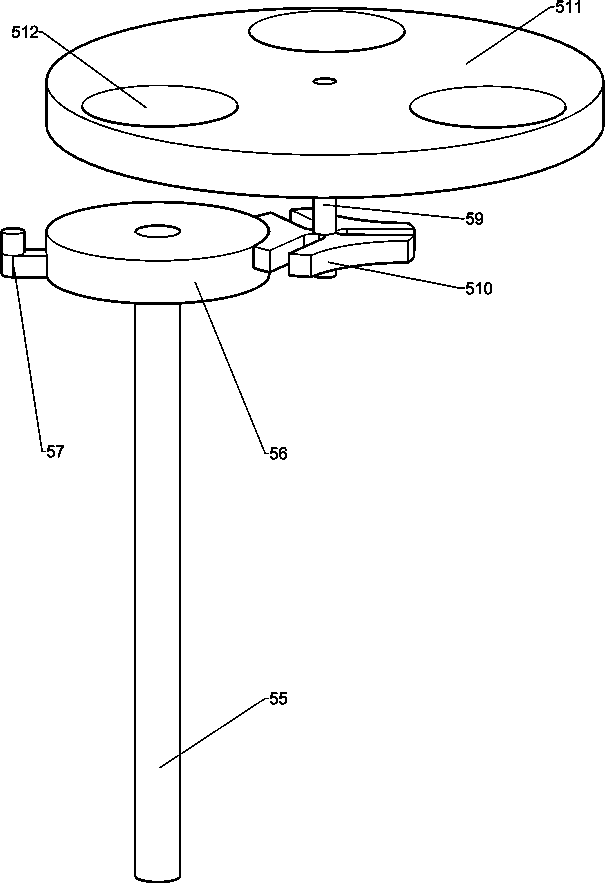

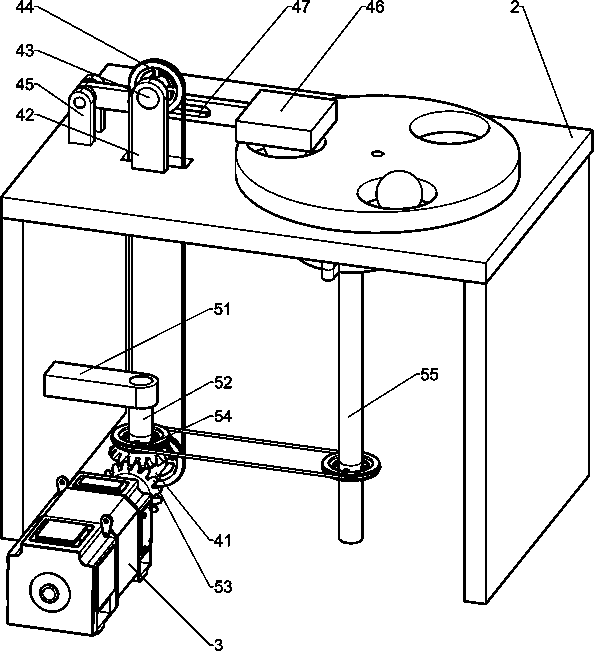

[0039] An automatic plum press, such as figure 1 As shown, it includes a base 1, a workbench 2, a motor 3, a pressing mechanism 4 and an intermittent feeding mechanism 5, a workbench 2 is provided in the middle of the base 1, a square hole is opened on the right side of the top of the workbench 2, and a square hole is opened on the right side of the base 1. A motor 3 is installed on the rear side, a pressing mechanism 4 is arranged on the right side of the top of the workbench 2, and the pressing mechanism 4 is connected with the motor 3, and an intermittent movement is provided between the left side of the top of the workbench 2 and the base 1 directly below the workbench 2. Material mechanism 5, intermittent feeding mechanism 5 is connected with pressing mechanism 4.

[0040] When the plums need to be pressed, the plums are first placed in the parts of the intermittent feeding mechanism 5, then the motor 3 is started, and the output shaft of the motor 3 drives the parts in t...

Embodiment 2

[0042] according to Figure 1-4 As shown, the pressing mechanism 4 includes a transmission shaft 41, a first support rod 42, a first rotating rod 43, a first belt assembly 44, a mounting seat 45 and a pressing plate 46, and the output shaft of the motor 3 is connected with a transmission shaft 41. A first support rod 42 is installed on the right side of the top of the platform 2, and a first rotating rod 43 is arranged on the upper part of the first supporting rod 42, and a first belt assembly 44 is connected between the first rotating rod 43 and the front side of the transmission shaft 41. The first belt assembly 44 passes through the square hole on the workbench 2, the right side of the top of the workbench 2 is provided with a mounting seat 45, the mounting seat 45 is located at the right front side of the first support rod 42, and the upper part of the mounting seat 45 is swingably provided with a pressing plate 46, A chute 47 is provided in the middle of the pressing plat...

Embodiment 3

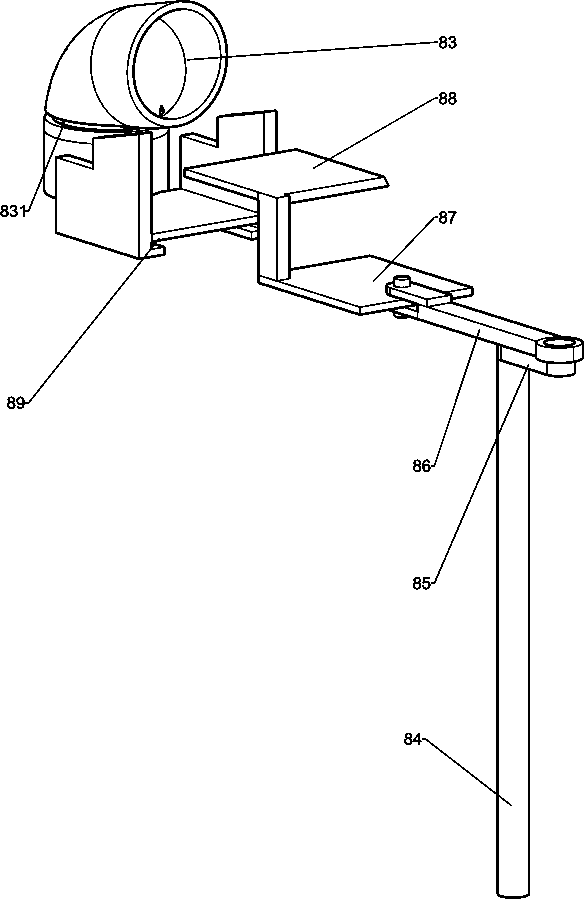

[0047] Specifically, such as figure 1 with Figure 5-8 As shown, a collection mechanism 6 is also included, and the collection mechanism 6 includes a collection frame 61 and a feeding tube 63. The front side of the base 1 is provided with a collection frame 61, and the workbench 2 directly below the frontmost delivery frame 512 is provided with a bottom frame. Feeding hole 62, the bottom of the top wall of workbench 2 is connected with feeding pipe 63, and feeding pipe 63 is positioned at the bottom of feeding hole 62, and the end of feeding pipe 63 is positioned at the upper part of the left rear side of collecting frame 61.

[0048] After the plums are pressed, the projection 57 is engaged with the sheave 510, and the plums in the feeding tray 511 and the feeding frame 512 rotate clockwise for 120 degrees and stop, and the next plum to be pressed turns to the pressing plate 46. directly below, and the pressed plums rotate into the feeding hole 62, and the pressed plums fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com