Self-polishing marine antifouling paint composition comprising fibres and metal-containing co-polymers

A marine antifouling and composition technology, applied in the field of antifouling paint, can solve problems such as cracks and flakes

- Summary

- Abstract

- Description

- Claims

- Application Information

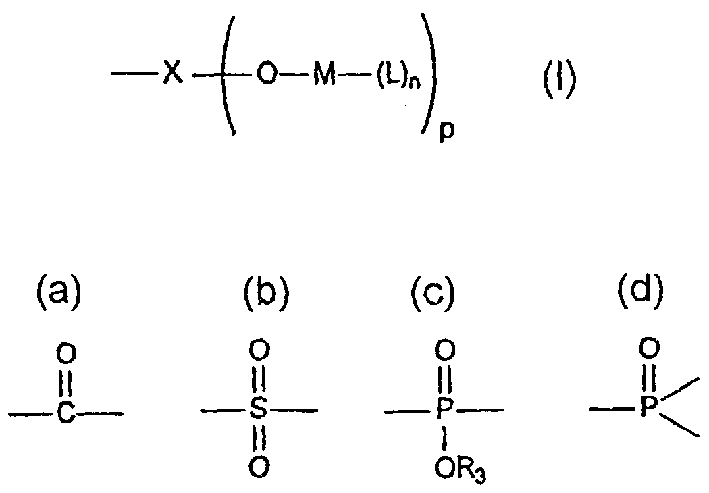

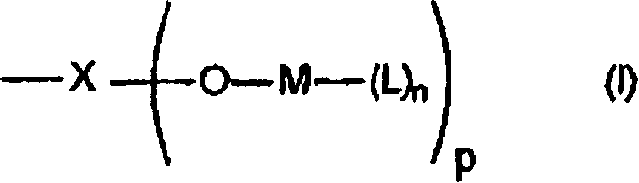

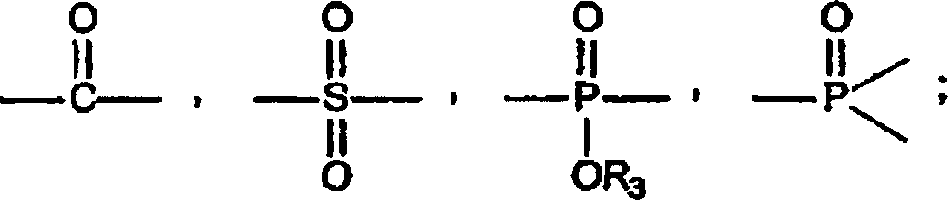

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0253] Plate preparation

[0254] Acrylic panels (155 x 100 x 5 mm) were first coated with an 80 μm (dry film thickness, DFT) commercial vinyl tar primer (Hempanyl 16280 from Hempel's Marine Paints) applied by air spraying. After drying in the laboratory at room temperature for 12-36 h, the antifouling paint (commercial paint) was applied in the following manner. A template (acrylic plate (155 x 100 x 5 mm) with 4 holes (diameter = 41 mm)) was placed and fixed on top of the previously primed plate. Weigh the antifouling paint with viscosity adjusted to 70-75KU into one of the holes. The amount of antifouling paint weighed into the well corresponds to a final DFT of 250 μm or 450 μm (specified according to the specific example). The paint is spread along the surface of the hole by the circular motion of the plate. Four paints (one in each well) can be applied per plate. The samples were removed 1-1.5 h after the end of application. Plates were dried in the laboratory at ro...

Embodiment 1

[0321] Model paint composition B (without fibers) and model paint composition B1 (with fibers) were prepared as described above.

[0322] The fiber materials employed were Lapinus Rockfibre MS 600 from LapinusFibres and F PAC O 245 / 040 from Schwarzwalder Textil-Werke.

[0323] The model paints were subjected to blister box tests and the results obtained are summarized in Tables 1.1-1.2 (DFT 250 μm) and 1.3-1.4 (DFT 450 μm):

[0324] Table 1.1: Crack density, DFT 250 μm

[0325] Crack density observed after:

[0326] paint composition

[0327] 1 day 24(week) 29(week)

[0328] B (without fiber) 0 1 2

[0329] B1 (with MS 600 fiber) 0 0 0

[0330] B1 (with F PAC O 245 / 040 fibers) 0 0 0

[0331] Table 1.2: Crack size, DFT 250μm

[0332] Crack size observed after:

[0333] model paint composition

[0334] 1 day 24(week) 29(week)

[0335] ...

Embodiment 2

[0353] Model paint composition C (without fibers) and model paint composition C1 (with fibers) were prepared as described above.

[0354] The fiber materials employed were Lapinus Rockfibre MS 600 from LapinusFibres and F PAC O 245 / 040 from Schwarzwalder Textil-Werke.

[0355] The model paints were subjected to blister box tests and the results obtained are summarized in Tables 2.1-2.2 (DFT 250 μm):

[0356] Table 2.1: Crack density, DFT 250 μm

[0357] Crack density observed after the following time:

[0358] paint composition

[0359] 1 day 19 24 29 (week)

[0360] C (without fiber) 0 1 1 3

[0361] C1 (with MS 600 fiber) 0 0 0 0

[0362] C1 (with F PAC O 245 / 040 fibers) 0 0 1 1

[0363] Table 2.2: Crack size, DFT 250μm

[0364] Crack size observed after:

[0365] model paint composition

[0366] 1 day 19 24 29 (week)

[0367] C (withou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com