Bamboo fibres and preparing process thereof

A processing method and bamboo fiber technology, which can be used in wood processing utensils, manufacturing tools, etc., can solve the problem that chemical preparations are not environmentally friendly products, and achieve the effects of easy promotion, simple process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

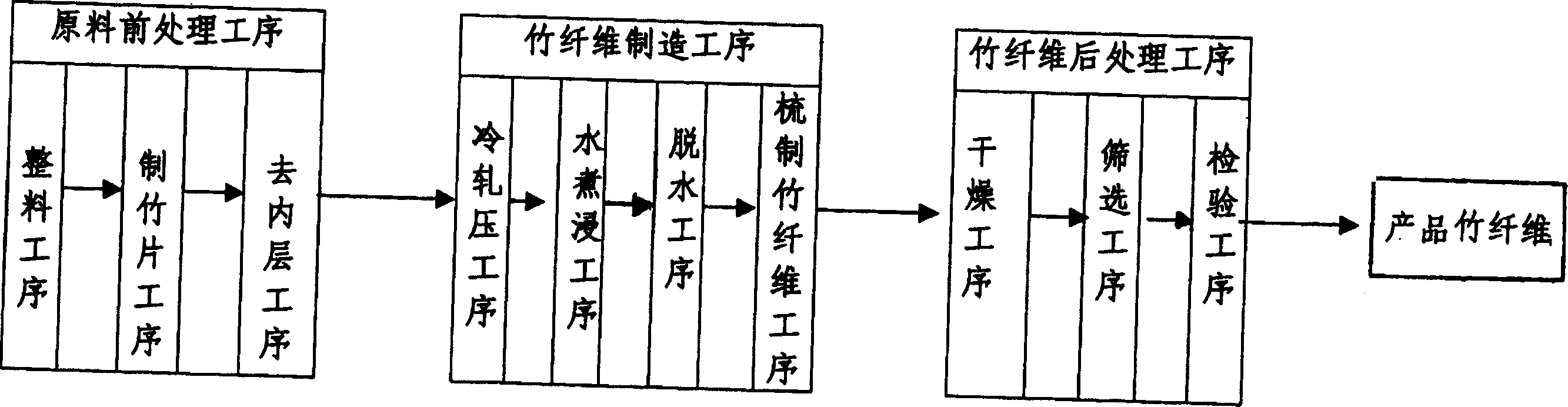

[0009] Combine below figure 1 Illustrate the concrete content that production process of the present invention comprises:

[0010] ① Whole material process: that is to remove the branches and tips of the raw bamboo, and use the part of the bamboo with a diameter greater than 4 cm to saw into a fixed-length bamboo tube;

[0011] ② Bamboo chip making process: that is, the bamboo tube is split into bamboo chips of a certain size range on a bamboo smashing machine or by hand;

[0012] ③Remove the inner layer process: that is to remove the inner bamboo joints and the inner layer with less fiber content on the bamboo slices;

[0013] ④Cold rolling and pressing process: that is, cold rolling and pressing of bamboo chips into dehydrated thin bamboo chips;

[0014] ⑤Water soaking process: that is to boil and soak the cold-rolled thin bamboo slices in water at 100±5°C to desugar, degrease, and sterilize for no less than 20 minutes to become bamboo fibers;

[0015] ⑥Dehydration proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com