Pneumatic telescopic-pendulum-adsorption medicine-plate conveying mechanism

A conveying mechanism, pneumatic technology, applied in the improvement field of safety interface, can solve the problems of high cost and high management cost, achieve stable conveying, improve production efficiency, advanced and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

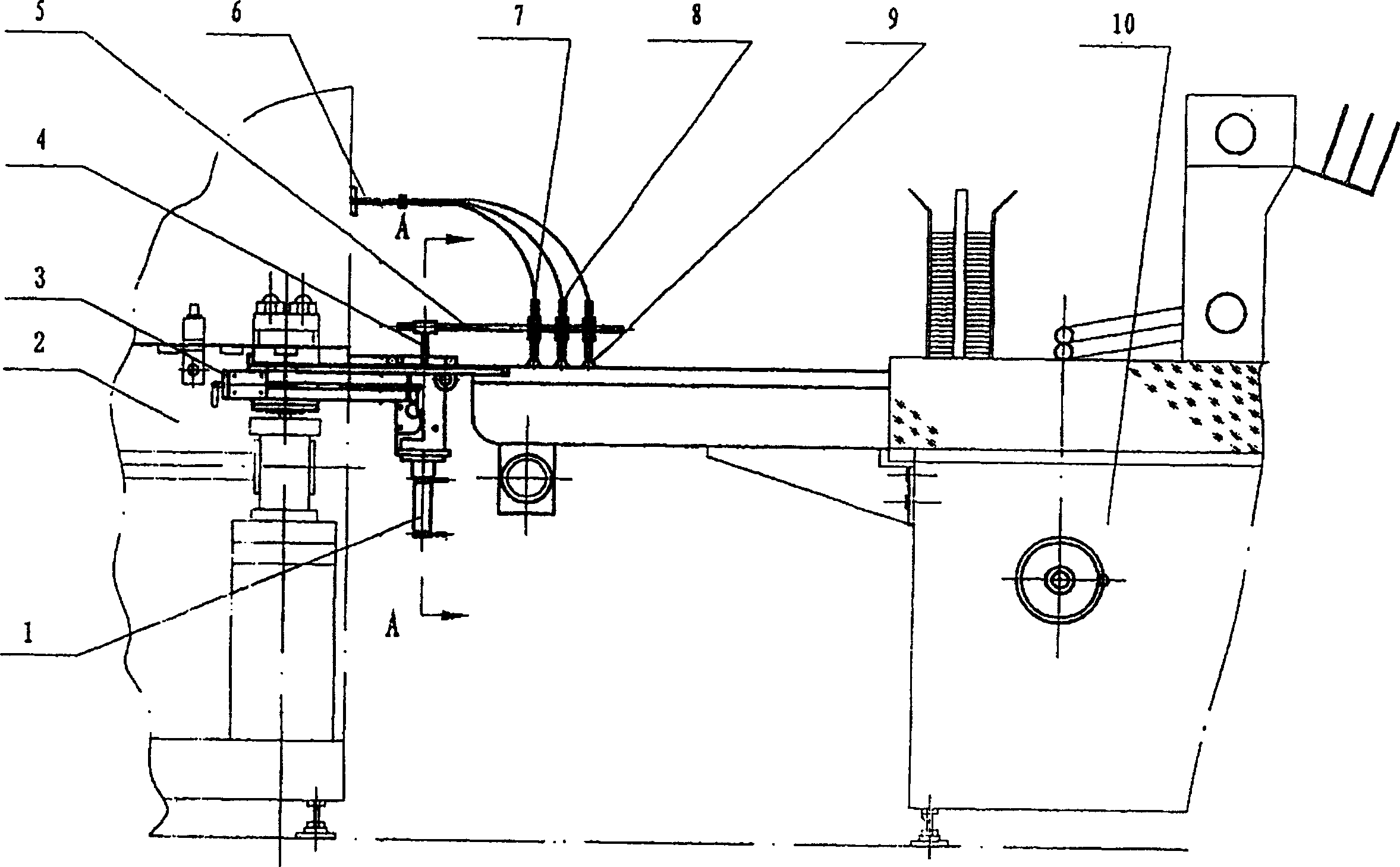

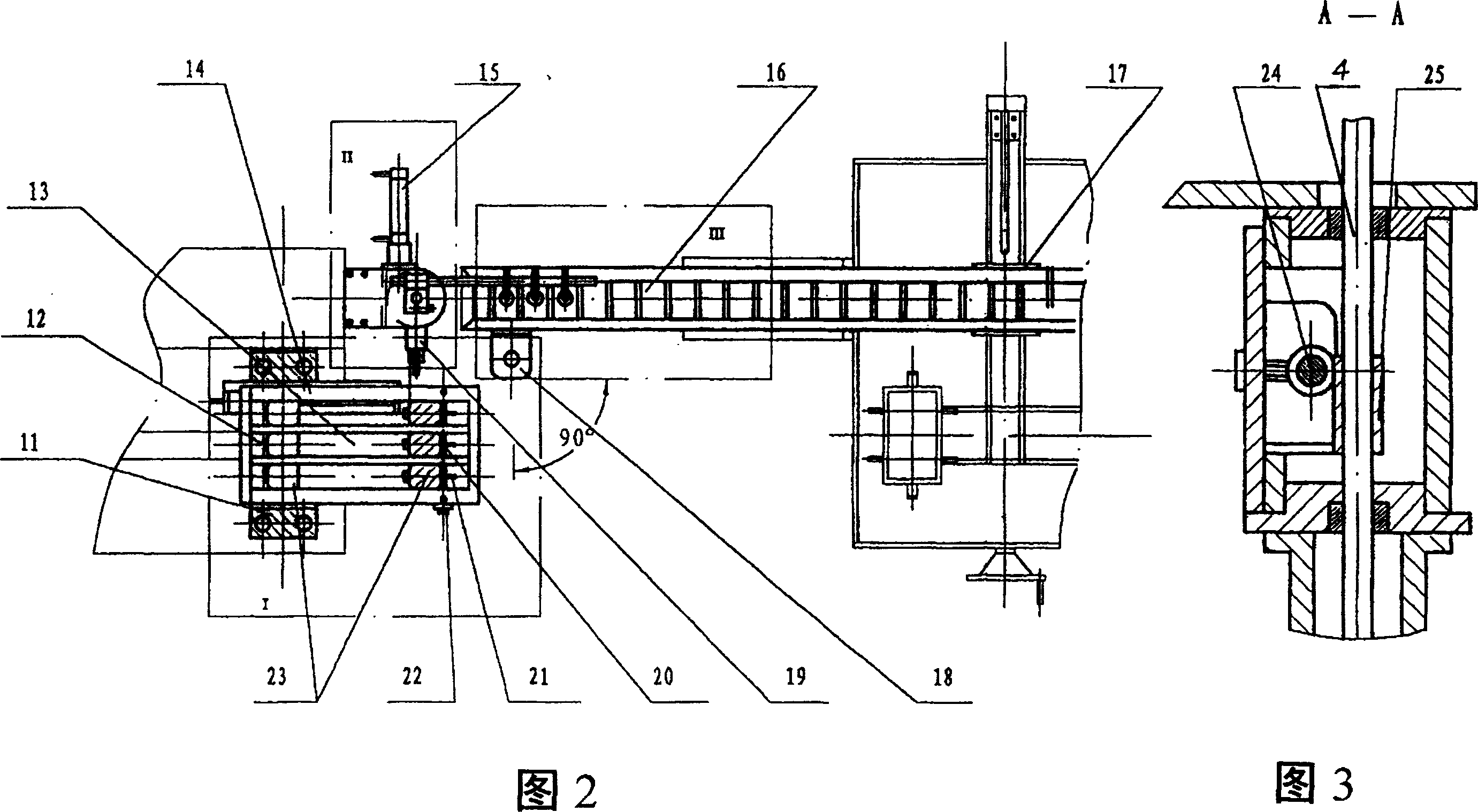

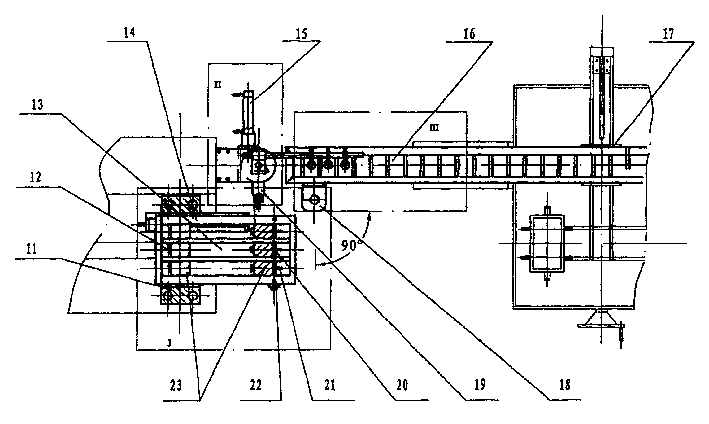

[0014] The accompanying drawings have shown the structure of the present invention, and the structure and principle of the present invention will be further elaborated below in conjunction with the embodiments. The present invention is arranged at the interface between the aluminum-plastic blister packaging machine 2 and the automatic medicine plate boxing machine 10, and the output positioning device I of the punching and receiving medicine plate, the stretching and swinging adsorption medicine plate indexing device II and the medicine plate conveying The device III consists of three parts, and the described punching and receiving plate output positioning device 1 includes a connecting guide plate 14 arranged on the punching die frame 11 of the aluminum-plastic blister packaging machine, a push plate cylinder 3 and a push plate cylinder located under the connecting guide plate 14. Medicine plate positioning card 20; the described pendulum adsorption medicine plate indexing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com