Industrial robot control method based on big data clustering

A technology of industrial robots and control methods, which is applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., and can solve problems such as insufficient control precision of robots, large deviations in running trajectories, independent research and development capabilities and application levels of industrial robots that have not reached expected standards, etc. , to achieve high economic value, small running track deviation, and high real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

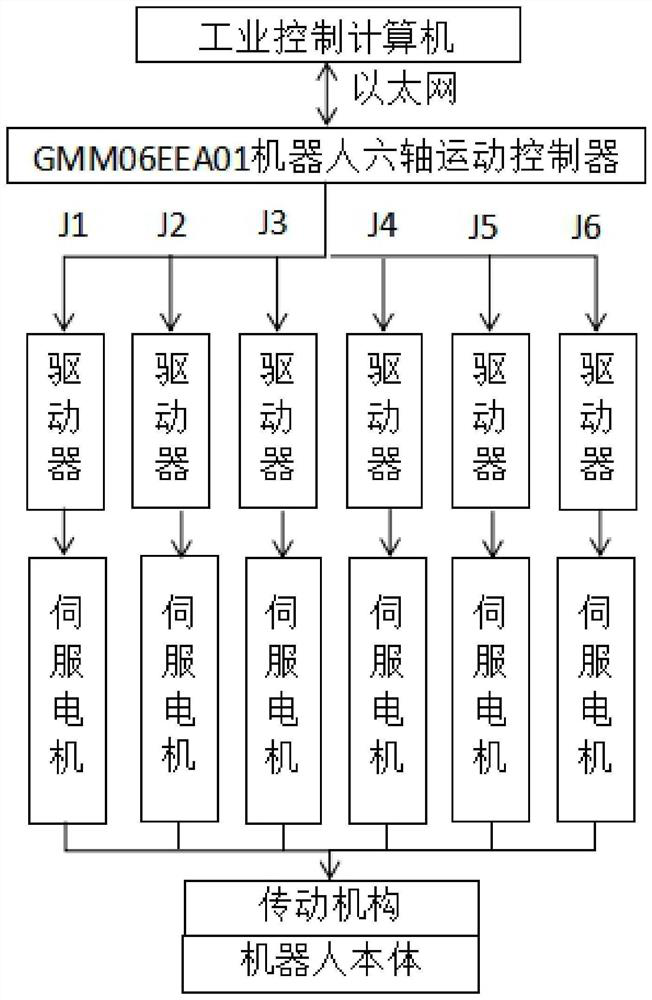

[0044] according to figure 1 As shown, this embodiment proposes an industrial robot control method based on big data clustering, including the following steps:

[0045] Step 1: Control Connection

[0046]Use the industrial control computer as the upper computer structure of the system, select the GMM06EEA01 robot six-axis motion controller to connect the industrial control computer with the servo motor and the driver, use the servo motor to cooperate with the transmission structure to control the robot body, and the GMM06EEA01 robot six-axis motion controller through Ethernet Connect with the industrial control computer, the GMM06EEA01 robot six-axis motion controller communicates with the servo at high speed through EtherCAT to realize the precise pose control of the robot. communication to realize the teaching and monitoring of the robot; the control of the robot is completed in the form of a two-level computing structure, and the industrial control computer is used as the ...

Embodiment 2

[0064] This embodiment proposes an industrial robot control method based on big data clustering. The overall trajectory planning is performed on the industrial control computer, and the outline method is used to coordinate and control the motion of each axis point of the industrial robot on the GMM06EEA01 robot six-axis motion controller. The specific planning process is:

[0065] S1: Use the interpolation trajectory algorithm to construct the trajectory mathematical equation, and calculate the specific position coordinates of the next interpolation point;

[0066] S2: Use kinematics reverse solution to obtain the rotation angle of each joint on the coordinates of the interpolation point, and obtain the position of the joint interpolation point of the industrial robot and the angular deviation from the previous interpolation point;

[0067] S3: Calculate the incremental value of each joint of the industrial robot, and write the incremental value into a file in dms format;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com