Method and system and device for producing components with pre-determained surface appearance, in particular for front panels of kitchen units

A technology for the outer surface and front panel, applied in the direction of duplication/marking method, joining of wooden veneers, manufacturing tools, etc., can solve the problems of single appearance, high cost, etc., and achieve the effect of increasing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] figure 1 Two front panels 2 are shown by way of example, the left front panel having a wooden outer surface with a textured pattern 4 and the right front panel having a uniform synthetic material outer surface. The front panel can have various structures and exterior surfaces, such as a fibreboard substrate to which wood veneer is mounted, a composite material substrate to which materials are bonded or laminated so that the exterior surface is three-dimensionally way constituted, and so on. The front panel can also be made from large blocks of wood.

[0026] The dotted line 6 represents the contour lines of various sizes required for the front panel, so that a non-rectangular front panel, a round or oval front panel, etc. can be provided.

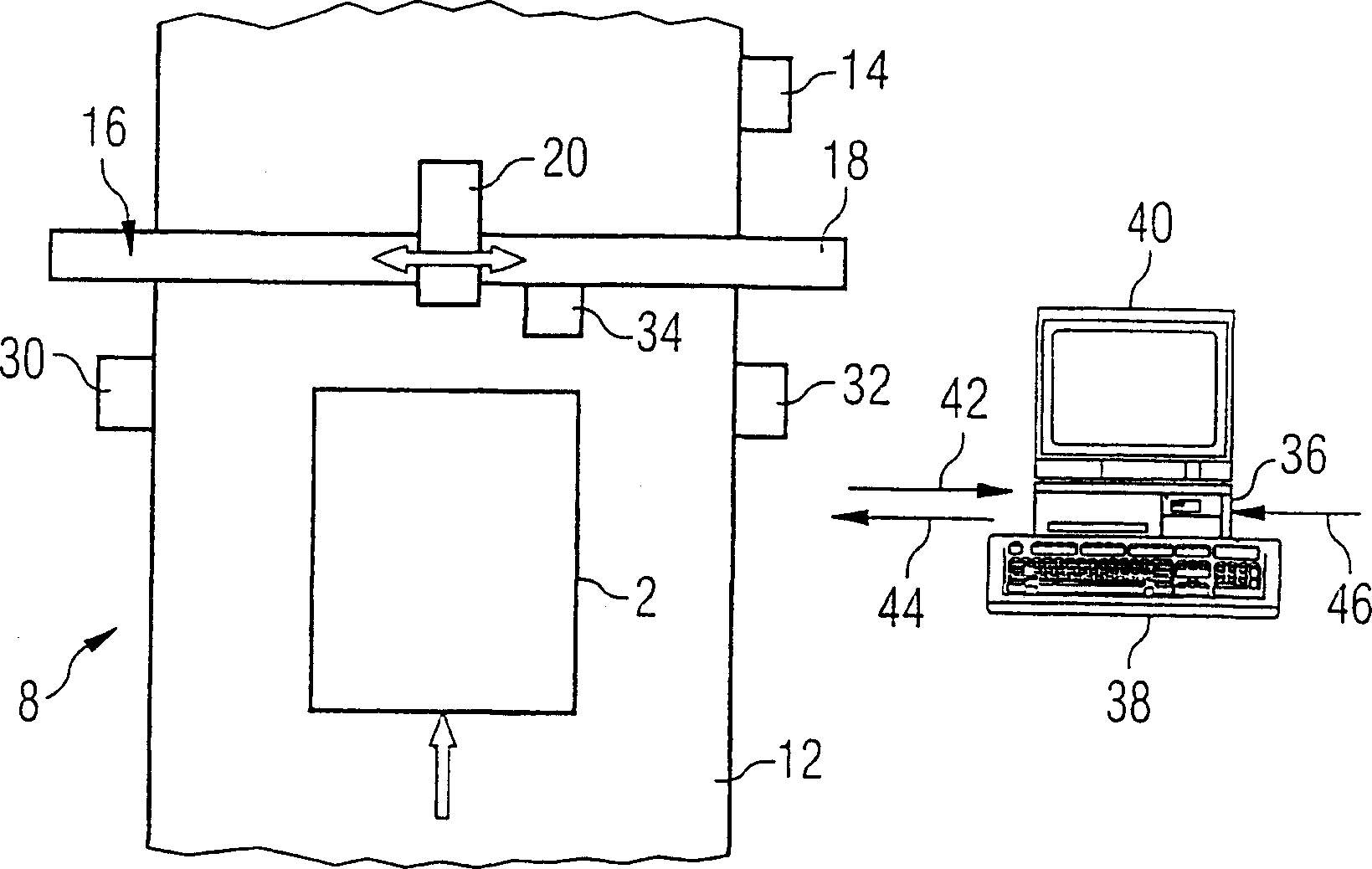

[0027] Figure 2A shows a plan view and Figure 2B shows a side view of the apparatus for producing a selected pattern on the front panel 2.

[0028] The front panel 2 is placed on a conveyor 8 comprising, for example, a conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com