Hand-held tool with dust extractor

A hand-held machine tool and vacuum device technology, which is applied in the direction of manufacturing tools, striking tools, light impact tools, etc., can solve the problem of plastic box clogging, and achieve the effect of avoiding dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

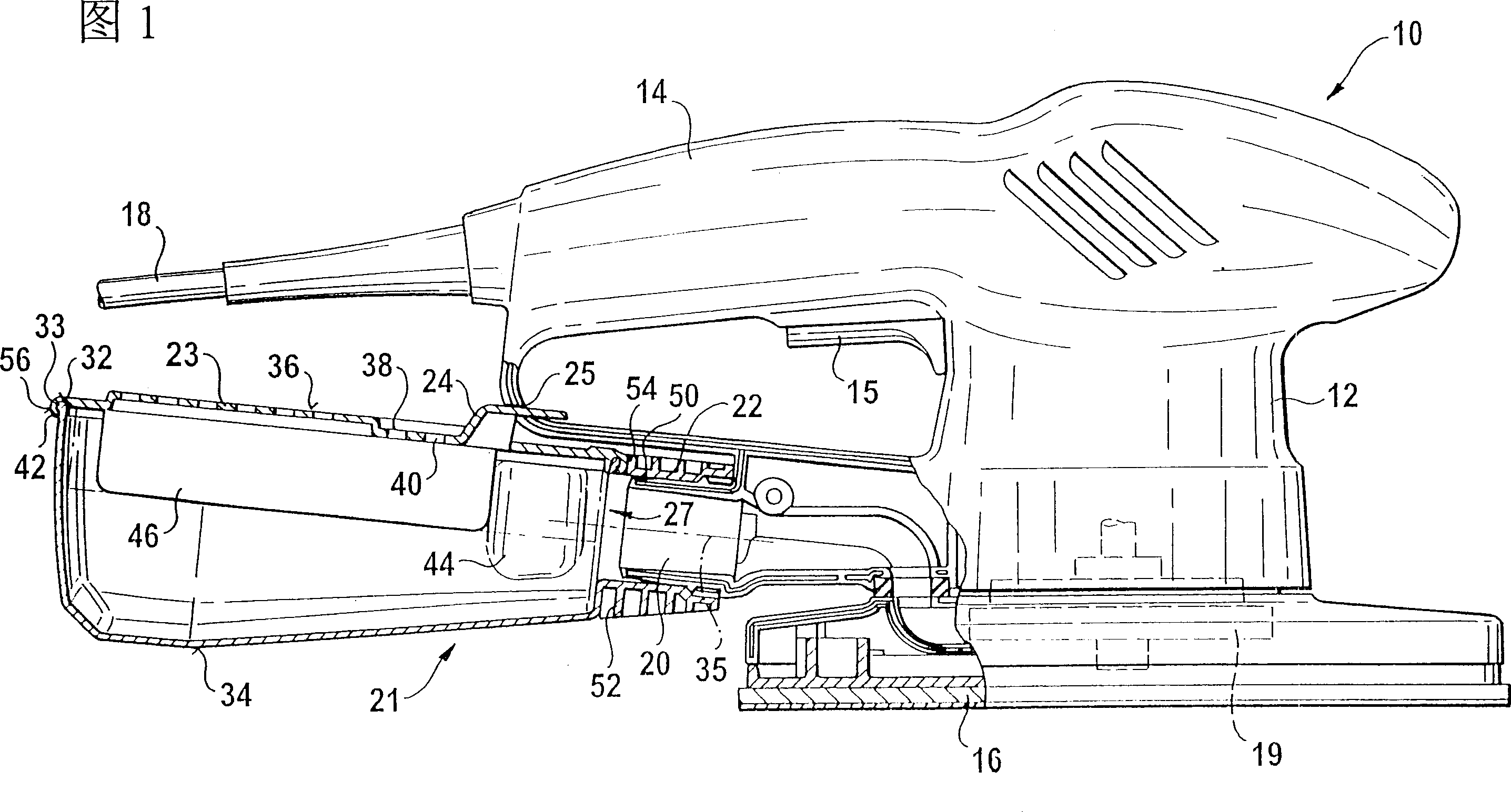

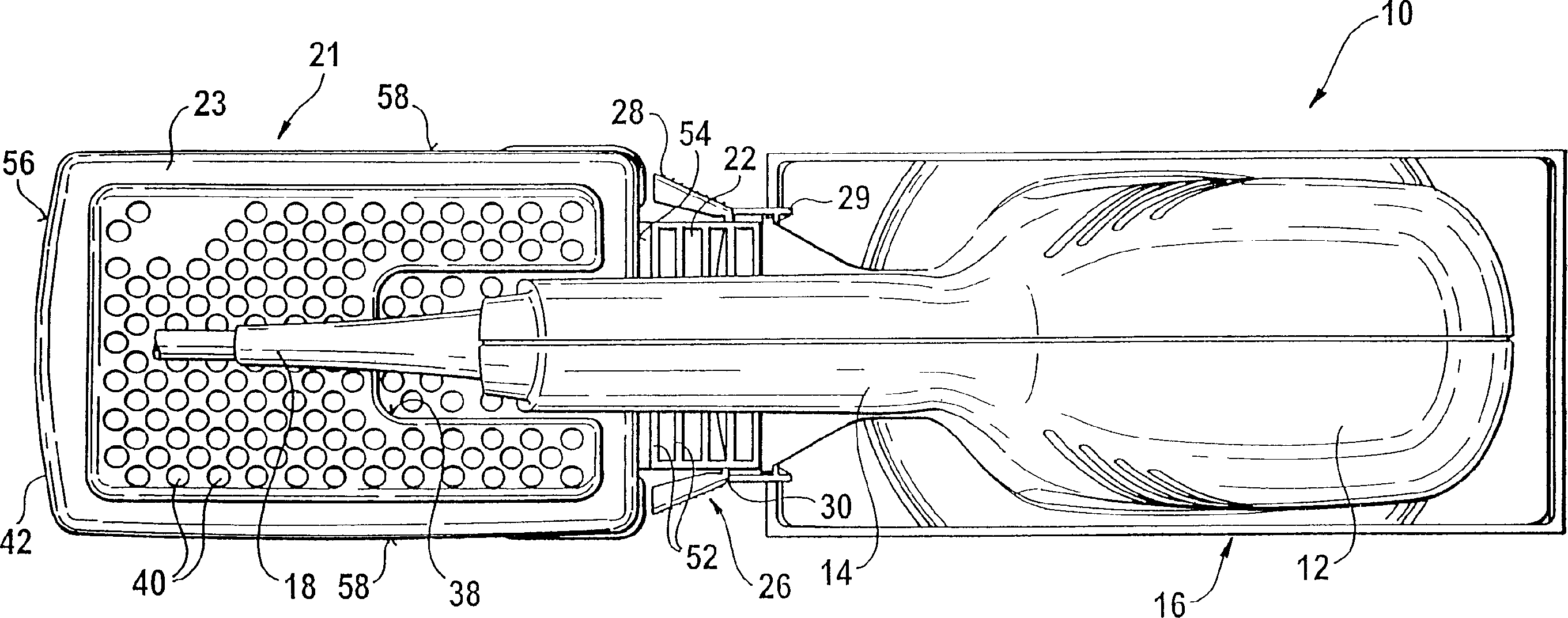

[0035] The longitudinal cross-sectional view of FIG. 1 shows a hand-held machine tool 10 constituting an ultra-finishing grinder. It has a housing 12 with a handle 14 with a switch 15 on which the structure is movably fixed Grinding plate for tool 16. The hand-held machine tool 10 has an electrical connection wire 18 at the rear end of the handle 14 and a ventilator rotor used as a dust suction device 19 inside the housing 12. The latter generates negative pressure on the grinding plate 16 when the hand-held power tool is working. As a result, the wear debris next to and below the grinding plate 16 is sucked in and blown through a discharge nozzle 20 of the housing 12.

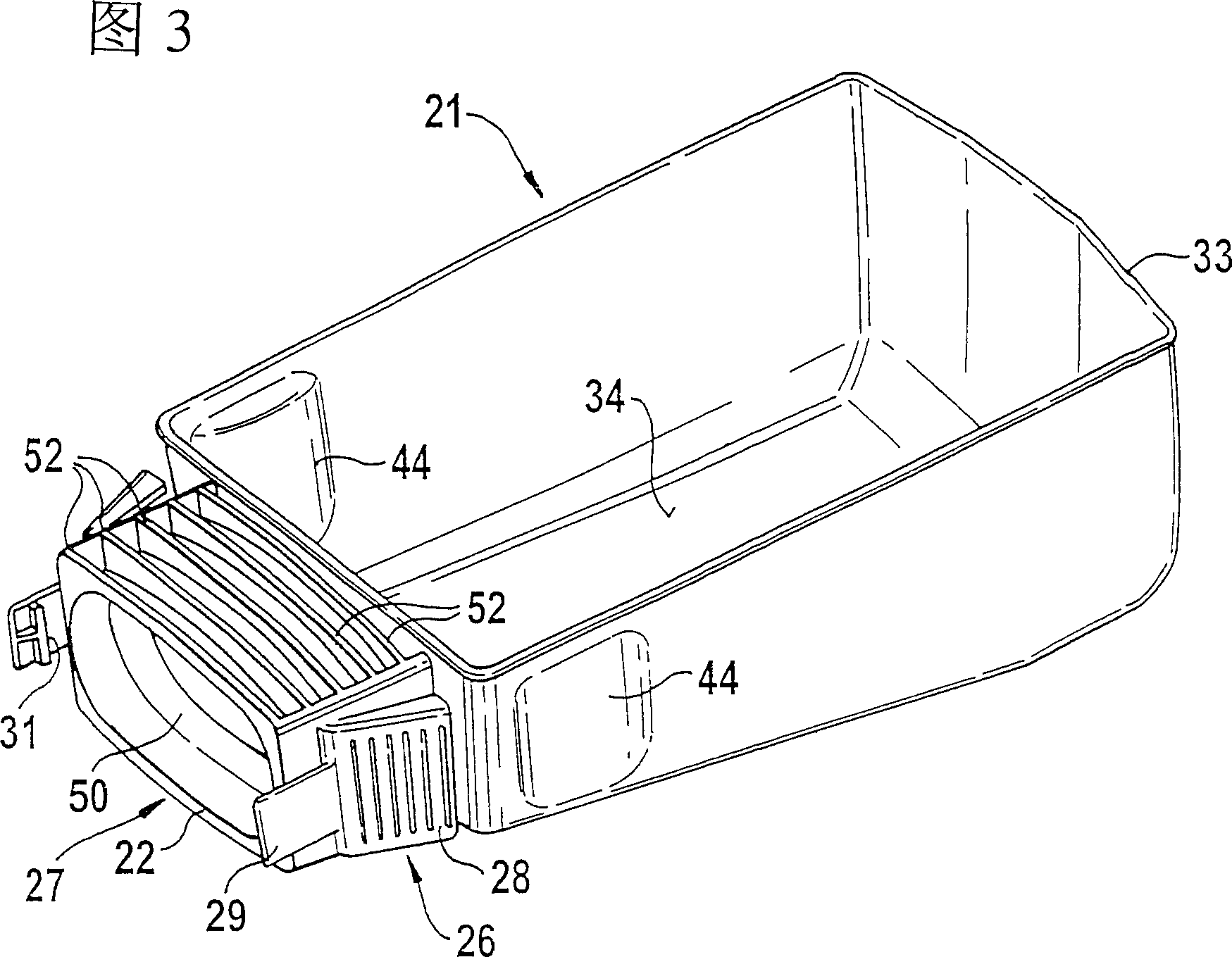

[0036] The discharge nozzle 20 carries a blow-in nozzle 22 of a cantilever-mounted dust box 21 with conformal rigidity sleeved thereon. It is airtight (up to the blowing port 27 of the blowing nozzle 22 and its upper side). The upper side of the dust box 21 is composed of a cover 23, and a hook 24 extends upward f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com