Method for in-line continuous detection of polymerization rate for polymerizing reaction of vinyl acetate

A vinyl acetate, polymerization technology, applied in the direction of analytical materials, instruments, etc., can solve the problems of high cost and time lag, and achieve the effect of low price, small lag time, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] How to implement the present invention will be described in detail below through an application example.

[0035] The process parameters and other parameters are: methanol ratio S is 15-20%; the polymerization rate range is 50% to 60%; the temperature range of the material in the polymerization tank is 55°C to 70°C; the ambient temperature range is -20°C to 45°C.

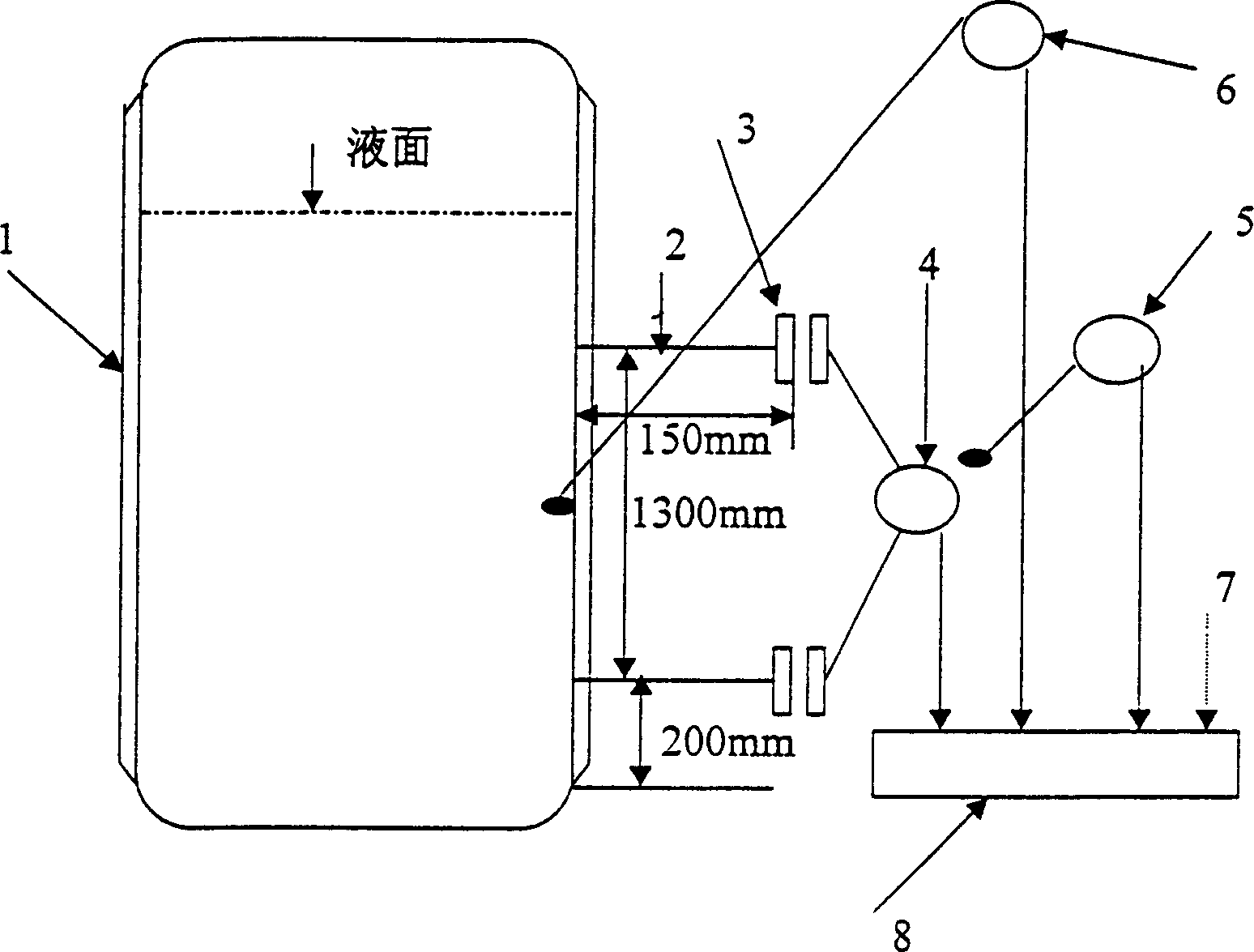

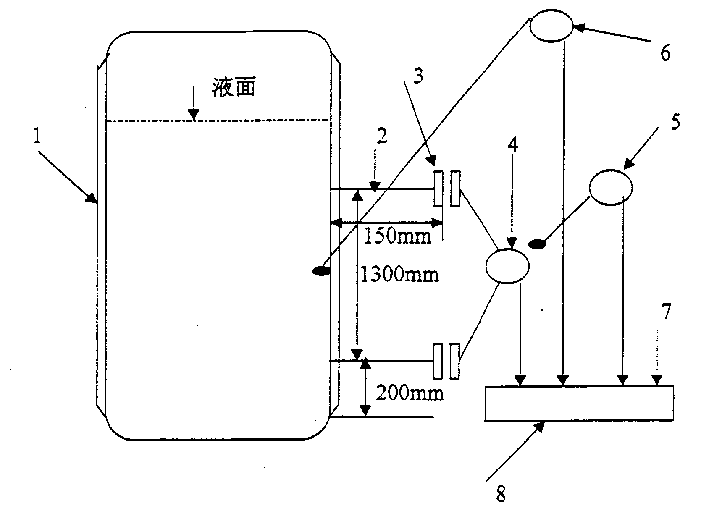

[0036] System configuration and installation such as figure 1 . The distance between the two pressure measuring points is 1300mm, wherein the bottom pressure measuring point is 200mm from the cylindrical lower end of the polymerization kettle along the line. The differential pressure signal is measured by a double-flange differential pressure transmitter, and the ambient temperature and material temperature are respectively measured by an ambient temperature transmitter and a material temperature transmitter. The above-mentioned measured differential pressure signal, ambient temperature signal, material te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com