Nondestructive inspection method for electric insulator steel foot and cast zinc ring combined face

A non-destructive testing and insulator technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as low work efficiency, detection results are easily affected by human factors, and high labor intensity, so as to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

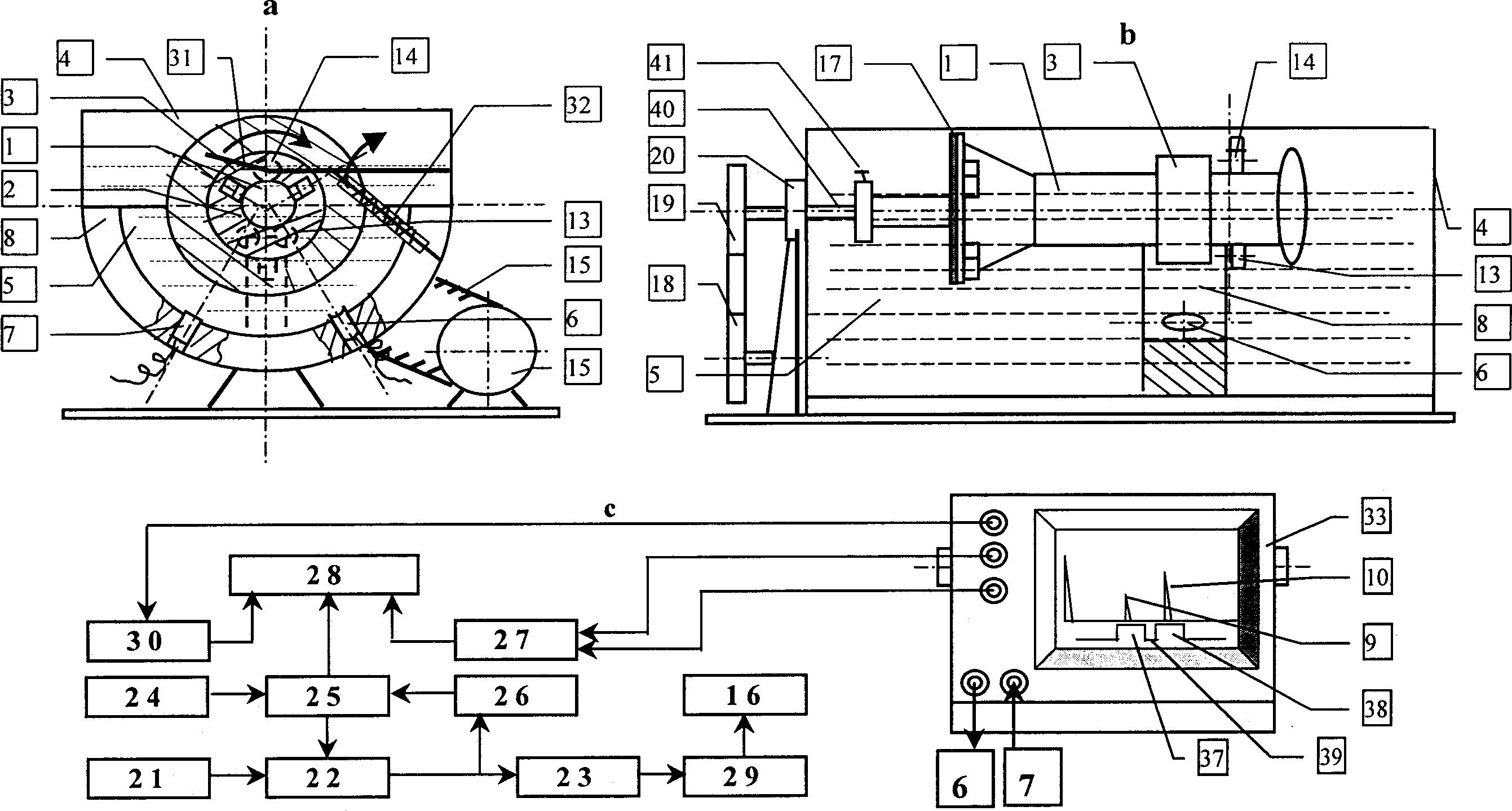

[0031] The best embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

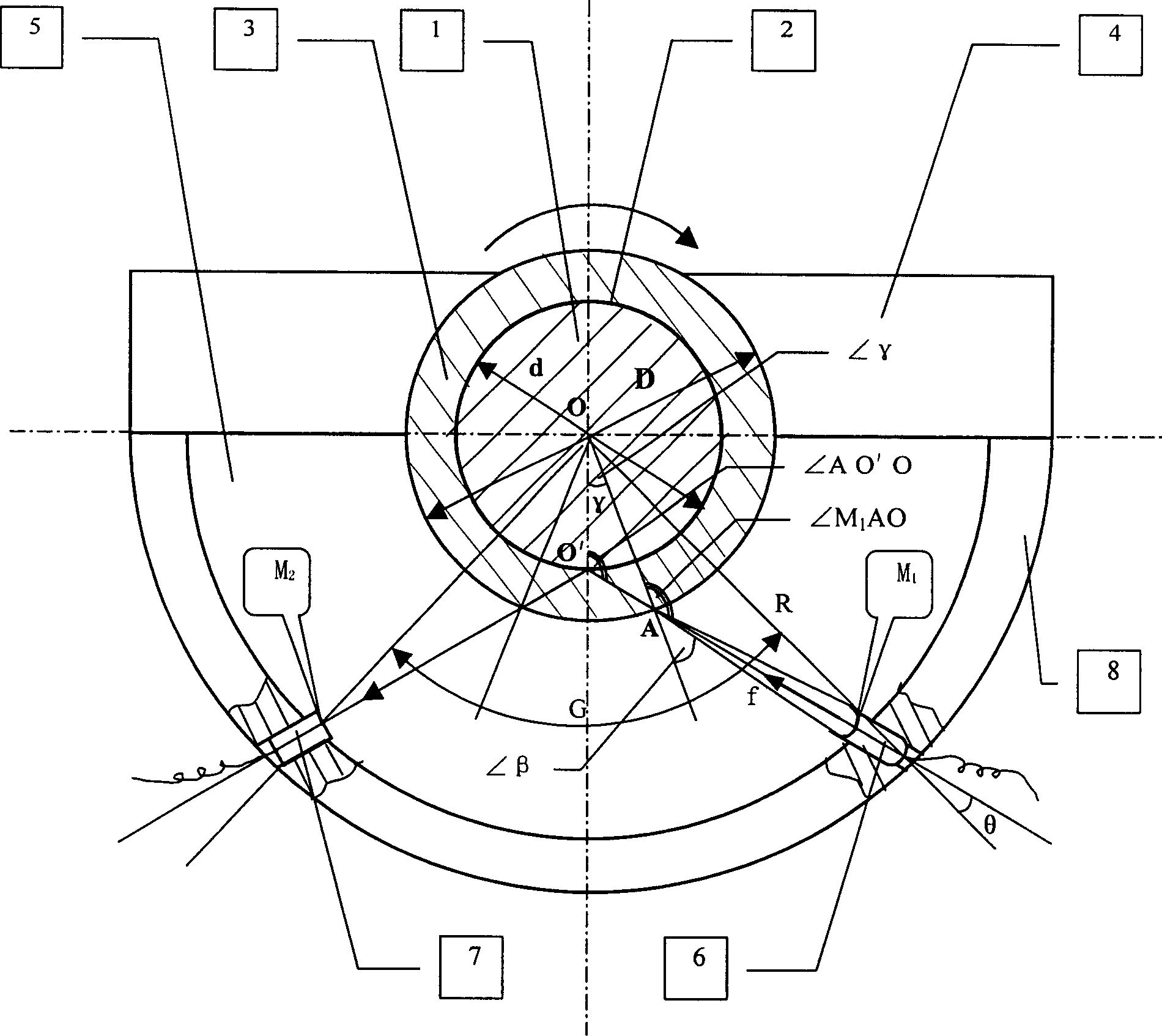

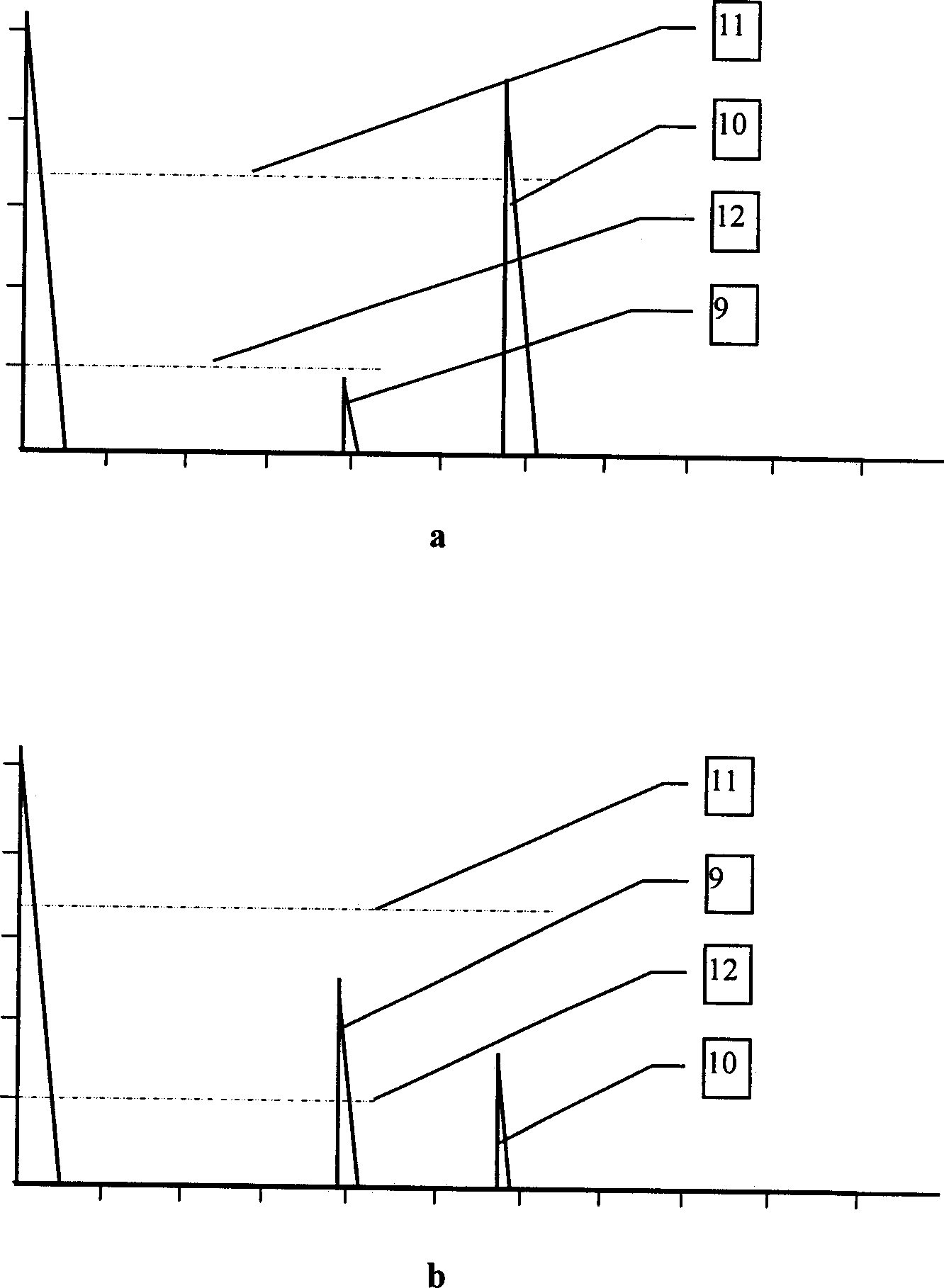

[0032] as attached figure 1 . Calculate and determine the distance and orientation relationship between the workpiece to be measured and the probe, take the centerline of the cylinder of the workpiece to be measured as the axis of rotation, and make a plane perpendicular to the above-mentioned axis at 1 / 2 of the axial length of the cast zinc ring 3, and the intersecting axis is at Point O, on this plane, take O as the center and R as the radius to make a semicircle, and pass through the center O to make two rays intersect the semicircle M 1 , M 2 point, and its included angle is G. The centers of the transmitting and receiving surfaces of the line-focusing longitudinal wave transmitting probe 6 and the planar receiving probe 7 are located at M 1 and M 2 point, the centerlines of the cylinders of the two probes are respectively relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com