Preparation method of multielement silicon water based well drilling liquid

A drilling fluid and silicon water-based technology, applied to drilling equipment, etc., can solve problems such as high interface permeability, poor cementing quality, and poor hydrophilicity, so as to improve cementation strength, improve channeling resistance, and increase mud cake strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0008] The preparation method of the multi-silicon water-based drilling fluid is as follows: the base slurry comprising 4.5-5.5 parts of bentonite, 0.15-0.25 parts of anhydrous sodium carbonate, and 94.25-95.35 parts of clear water is formed by parts by weight, and the molecular formula is Na 2 O nSiO 2 +3K 2 O mSiO 2 2-7 parts of silanol binder, 1-6 parts of carboxymethyl cellulose, molecular formula CH 3 Mix 2-5 parts of film-forming agent of Si(OH)ONa to make polysilicon solution, add 1.0-2.0 parts of this solution to 100 parts of base slurry, then add 0.5-1.0 parts of organosilicon potassium humate and sulfur 0.5-1.0 part of chemical extract can be evenly stirred.

[0009] The above molecular formula is Na 2 O nSiO 2 +3K 2 O mSiO 2 n=1.5-2.5 in the silanol binder, m=1.5-3.5; the molecular formula of carboxymethyl cellulose is (C 6 h 9 o 4 ·OCH 2 COOH) n , where n=230-260.

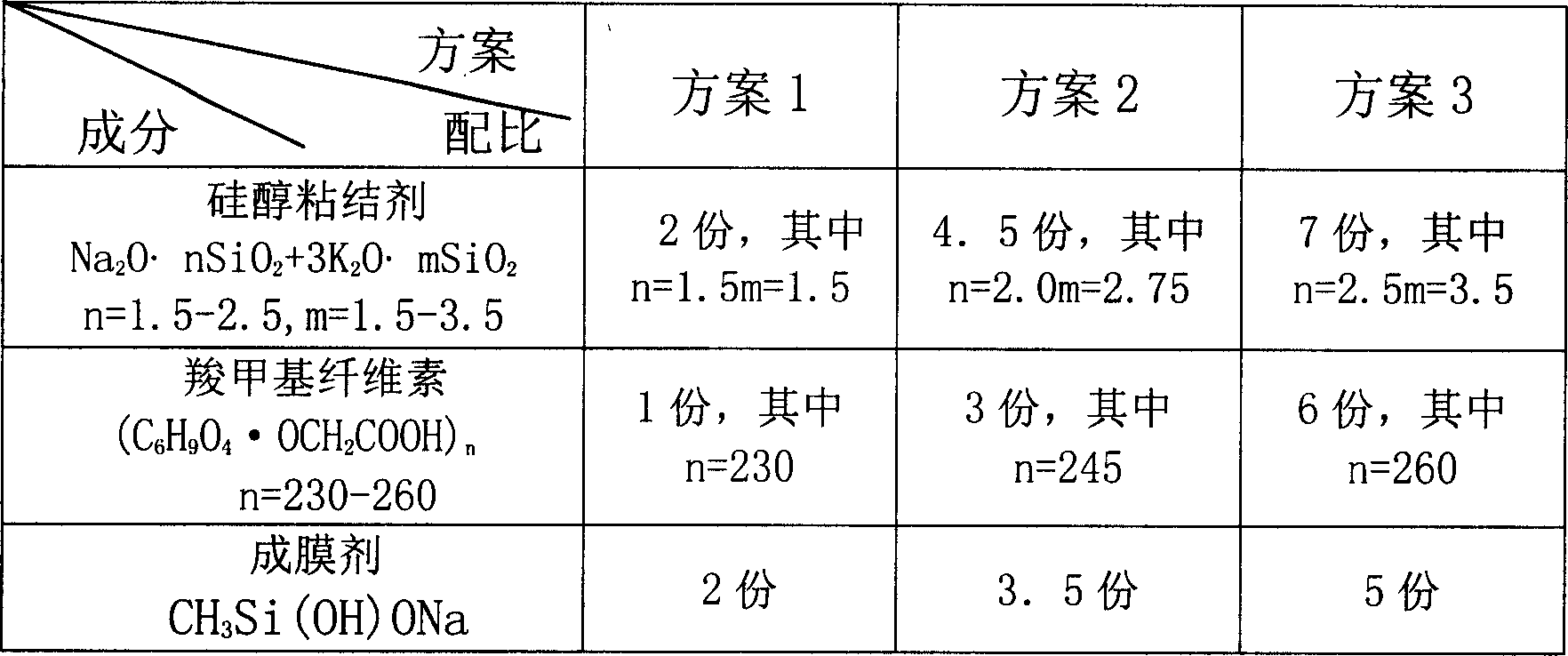

[0010] The specific preparation scheme of polysilicon solution is as follows:

[0011]...

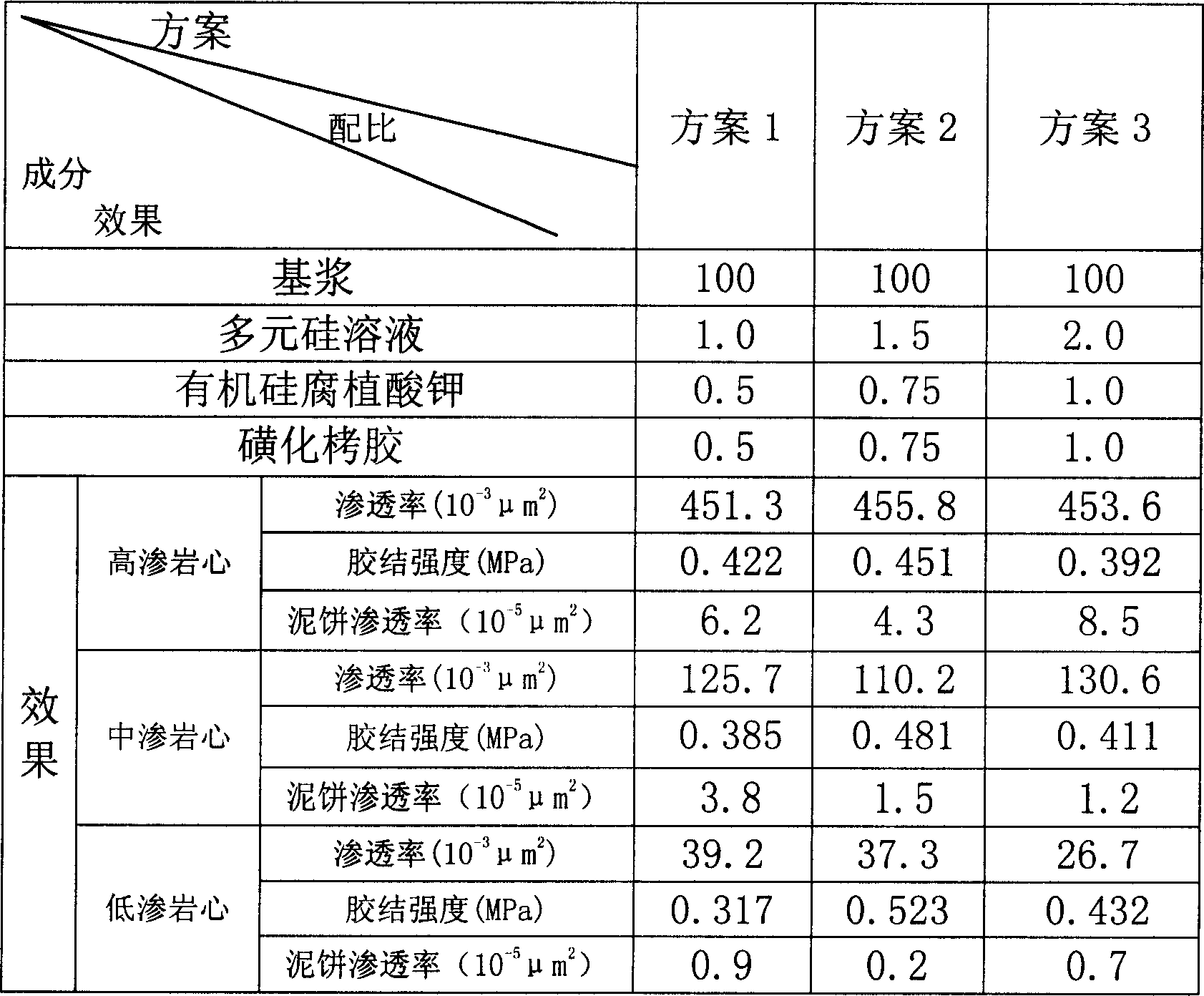

Embodiment 1

[0016] Example 1. During the construction of Well Xing 1-320-18 in Daqing, the multi-component silicon drilling fluid prepared in Scheme 1 in the above table was used. The secondary sound change was reduced by 1.20% compared with the primary sound change. The rheological property was reasonable and the inhibition was strong. The well diameter is regular, 98.1% of the well intervals are completely cemented at the first and second interfaces, the construction process is simple, the cost is low, the drilling fluid mud cake is thin, and the cementation strength of the second interface is high.

Embodiment 2

[0017] Example 2. During the construction of Well Xing 1-332-22 in Daqing, the multi-silicon drilling fluid prepared in Scheme 2 of the above table was used, and the secondary sound change decreased by 0.77% compared with the primary sound change. It is not because the content of multi-silicon is more The more the better, but in this program is the best, the cementing quality is in the best state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com