Organic electroluminescent device and its prepn. method

An electroluminescent device and device technology, applied in the field of device preparation, can solve the problems of complex preparation process and inapplicability of small molecule OLED devices, etc., and achieve improved luminous efficiency and stability, low lighting voltage and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

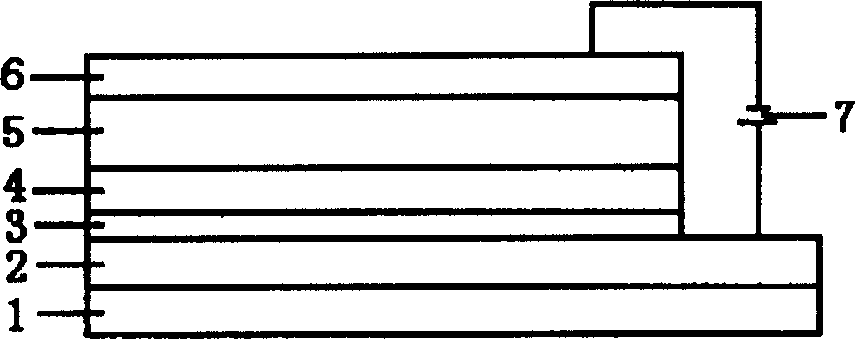

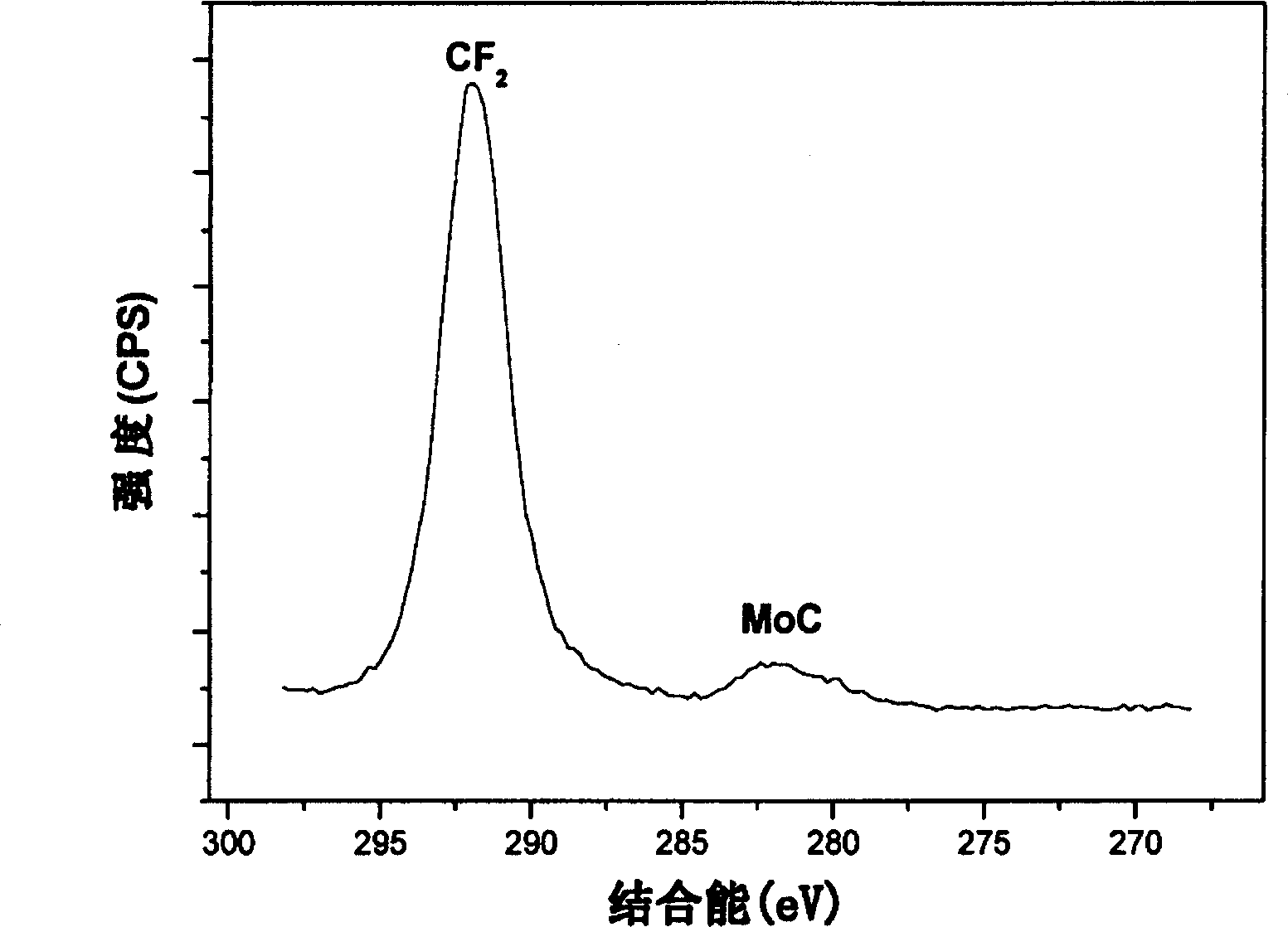

[0034]The ITO glass with a sheet resistance of 70Ω was cleaned and dried by boiling detergent and ultrasonic deionized water, and the film thickness of ITO was 100nm. Put the cleaned ITO glass under a pressure of 1×10 -3 In the vacuum chamber of pa, a Teflon buffer film is evaporated on the ITO film by thermal evaporation method, the evaporation rate is 0.04nm / s, and the film thickness is 2nm. On the Teflon buffer film, continue to vapor-deposit the hole transport layer NPB, the vapor deposition rate is 0.4nm / s, and the film thickness is 40nm. Continue to vapor-deposit organic functional layer Zn(Ac) on the NPB layer 2 , the evaporation rate is 0.2nm / s, and the film thickness is 60nm. In Zn(Ac) 2 The metal layer is continuously vapor-deposited on the layer, and the metal layer is sequentially composed of Mg-Ag alloy and Ag. The total evaporation rate of Mg-Ag is 1.5nm / s, and the ratio of Mg and Ag evaporation rates is 4:1. The film thickness is 100nm; the evaporation rate ...

Embodiment 2

[0036] The ITO glass with a square resistance of 60 Ω was cleaned and dried by boiling detergent and ultrasonic deionized water, and the film thickness of ITO was 180 nm. Put the cleaned ITO glass under a pressure of 1×10 -4 In the vacuum chamber of pa, a Teflon buffer film was evaporated on the ITO film by thermal evaporation method, the evaporation rate was 0.02nm / s, and the film thickness was 1nm. The hole transport layer TPD is continuously evaporated on the Teflon buffer film, the evaporation rate is 0.2nm / s, and the film thickness is 40nm. Continue to vapor-deposit the organic functional layer Alq on the TPD layer 3 , the evaporation rate is 0.1nm / s, and the film thickness is 60nm. in Alq 3 The metal layer is continuously evaporated on the layer, and the metal layer is composed of Ca and Ag in turn. The evaporation rates of Ca and Ag are 0.6nm / s and 0.3nm / s respectively, and the film thicknesses are 35nm and 130nm respectively. The lighting voltage of the device is 2...

Embodiment 3

[0038] The ITO glass with a sheet resistance of 30Ω was cleaned and dried by boiling detergent and ultrasonic deionized water, and the film thickness of ITO was 240nm. Put the cleaned ITO glass under a pressure of 1×10 -5 In the vacuum chamber of pa, a Teflon buffer film is evaporated on the ITO film by thermal evaporation method, the evaporation rate is 0.01nm / s, and the film thickness is 6nm. On the Teflon buffer film, the hole transport layer MTDATA was continuously evaporated, the evaporation rate was 0.2nm / s, and the film thickness was 40nm. Continue to vapor-deposit organic functional layer Zn(Ac) on top of MTDATA layer 2 , the evaporation rate is 0.2nm / s, and the film thickness is 40nm. In Zn(Ac) 2 The metal layer is continuously evaporated on the layer, and the metal layer is composed of Ca and Ag in turn. The evaporation rates of Ca and Ag are 0.8nm / s and 0.2nm / s respectively, and the film thicknesses are 25nm and 150nm respectively. The lighting voltage of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com