Multi-modal industrial process fault diagnosis method based on confrontation of local maximum mean value difference

A local maximum, industrial process technology, applied in the direction of comprehensive factory control, electrical testing/monitoring, etc., can solve problems such as difficulty in fault diagnosis and modeling, and achieve the goal of improving target modal fault diagnosis accuracy, reducing distribution differences, and improving performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

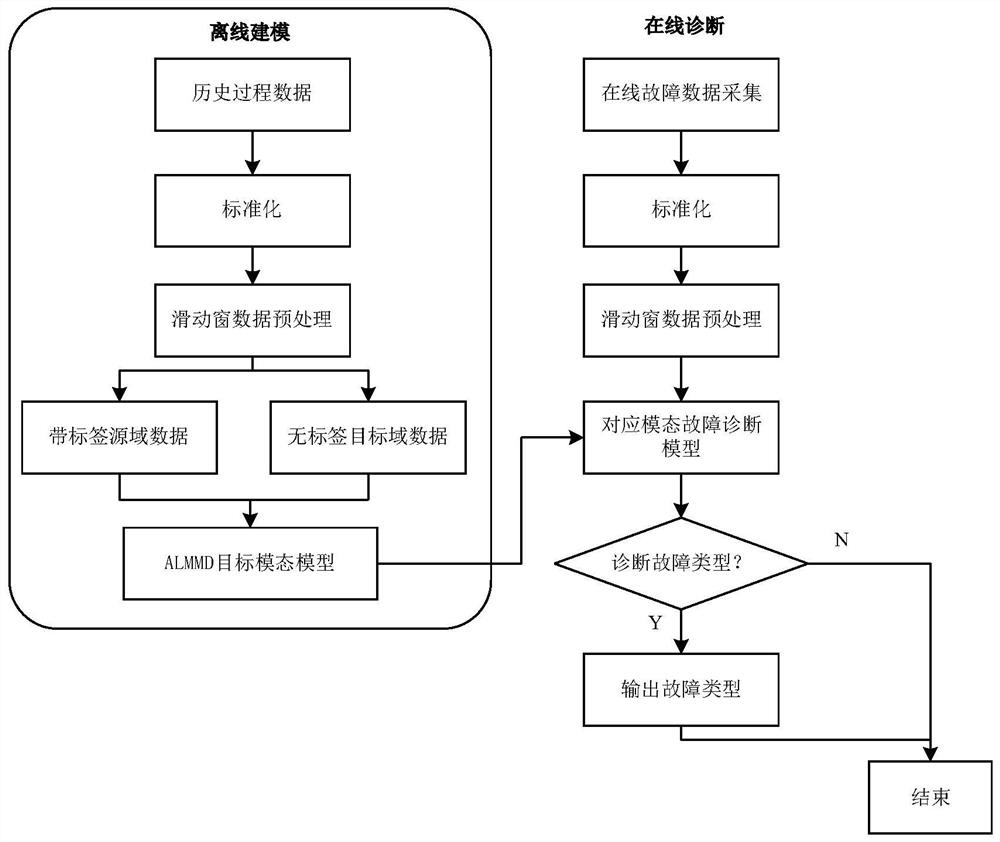

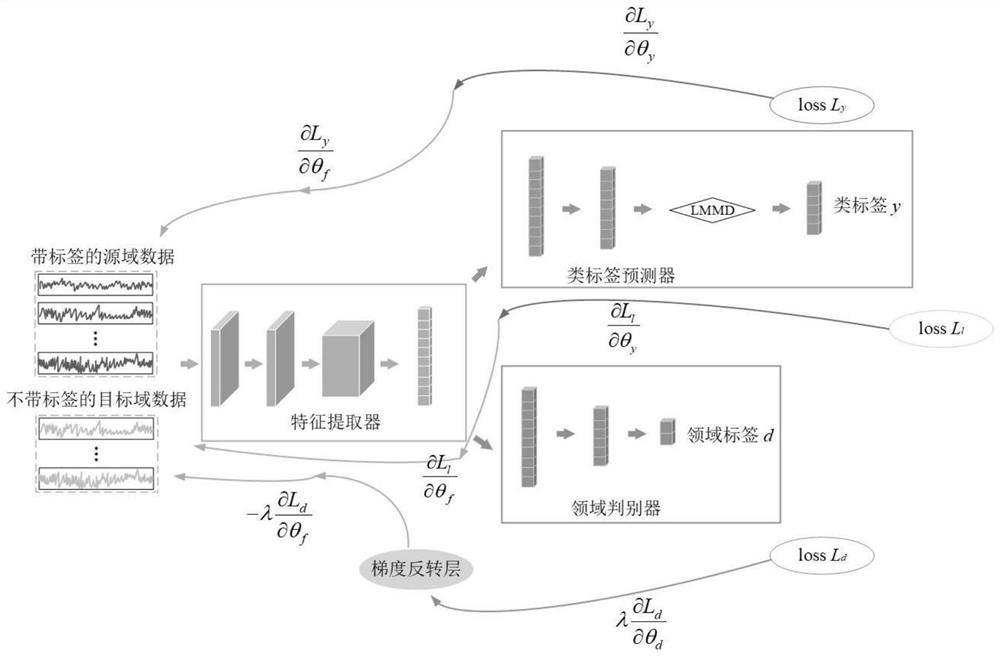

AI Technical Summary

Problems solved by technology

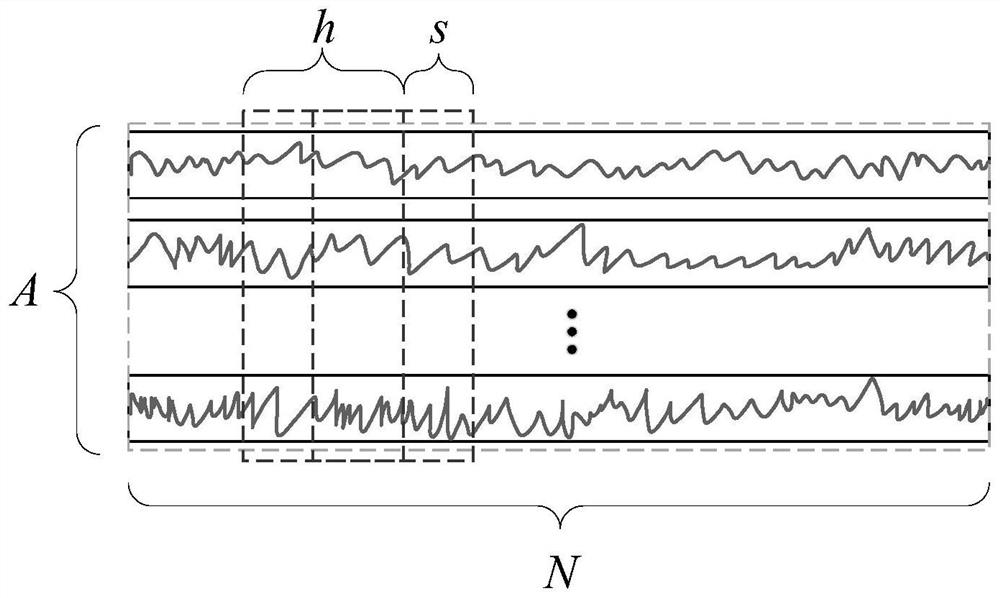

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is described in detail below in conjunction with actual process data:

[0058] The Tennessee-Eastman Process (TE Process) is a model that simulates an actual chemical process and is often used as a benchmark for testing fault diagnosis in complex multimodal industrial processes. The TE process contains five operating units: a reactor unit, a product separator unit, a condenser unit, a compressor unit, and a stripper unit. Based on the simulation model, the present invention performs experimental simulation on the multi-modal industrial process. As shown in Tables 1 and 2, 22 process variables and 19 component variables are selected, with a total of 41 observation variables. The process uses raw materials A, C and D. , E generate two liquid products G, H. According to the optimal operating conditions, three modes are set in the simulation, as shown in Table 3.

[0059] Set the sampling interval to 0.02 hours, and collect normal samples and fault s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com