Low-temperature long-service-life natural graphite negative electrode material as well as preparation method and application thereof

A technology of natural graphite and negative electrode materials, which is applied in the preparation/purification of graphite and carbon, battery electrodes, etc., and can solve problems such as the difficulty of covering multiple flake graphite layers, the inability to use natural graphite negative electrode materials, and the high viscosity of asphalt. Achieve the effects of improved cycle life, long service life, and good low-temperature charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

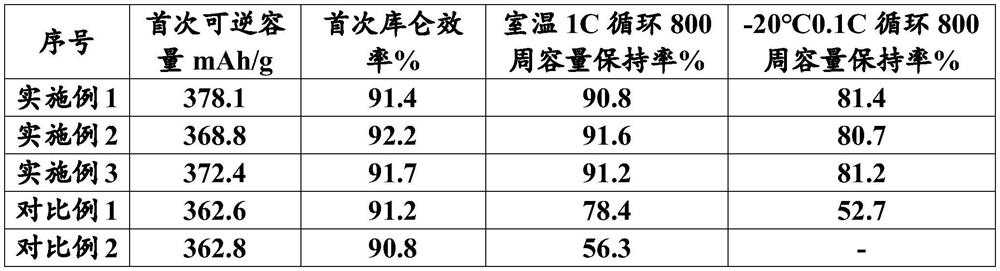

Examples

preparation example Construction

[0041] The preparation method of the present invention will be described in further detail below with reference to specific examples. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies implemented based on the above content of the present invention are covered within the intended protection scope of the present invention.

[0042] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents, materials, etc. used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0044] (1) Add 20 g of asphalt to 150 g of washing oil, and stir at high speed (20 r / min) to fully dissolve the asphalt to obtain an asphalt solution (kinematic viscosity at 100° C. 90 mPa·S);

[0045](2) put 100g natural graphite into the reactor, vacuumize for 60min, when the vacuum degree of the reactor reaches 0.07MPa, open the pitch solution suction valve, all the pitch solutions obtained in step (1) are sucked into the reactor, and the liquid feed is completed Then close the suction valve, stop vacuuming, and at the same time stir the mixture at a high speed (20r / min) for 40min, pressurize (12MPa) after immersion, depressurize to make the pressure inside and outside the reactor the same, pass nitrogen and heat to 230℃ remove wash oil;

[0046] (3) after all the washing oil in the reaction kettle of step (2) is discharged, under the condition that the pressure is 1.5MPa, the reaction kettle is heated to 410°C for 10h according to the heating rate of 5°C / min to carry out t...

Embodiment 2

[0050] (1) Add 25 g of asphalt to 200 g of naphthalene oil, and stir at high speed (30 r / min) to fully dissolve the asphalt to obtain an asphalt solution (kinematic viscosity at 100° C. 100 mPa·S);

[0051] (2) put 100g natural graphite into the reactor, vacuumize for 50min, when the vacuum degree of the reactor reaches 0.07MPa, open the pitch solution suction valve, all the pitch solutions obtained in step (1) are sucked into the reactor, and the liquid feed is completed Then close the suction valve, stop vacuuming, and at the same time stir the mixture at a high speed (30r / min) for 40min, pressurize (15MPa) after immersion, depressurize to make the pressure inside and outside the reactor the same, and heat it to 250℃ by introducing nitrogen remove naphthalene oil;

[0052] (3) after all the naphthalene oil in the reaction kettle of step (2) is discharged, under the condition that the pressure is 2.0MPa, the reaction kettle is heated to 420°C for 8h according to the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com