Natural graphite-based modified composite material and preparation method thereof, and lithium ion battery comprising modified composite material

A composite material and natural graphite technology, which is applied to the negative electrode material of lithium ion battery, its preparation, and the field of natural graphite-based modified composite material, can solve the problem that defect sites cannot be well improved, the material cycle performance has no qualitative improvement, and there is no qualitative improvement. Reveal the effects of improving the isotropy on the electrode expansion rate, and achieve the effect of improving the electrochemical performance, reducing the electrode expansion rate, and having a high degree of isotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

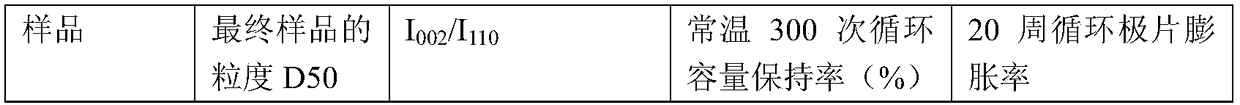

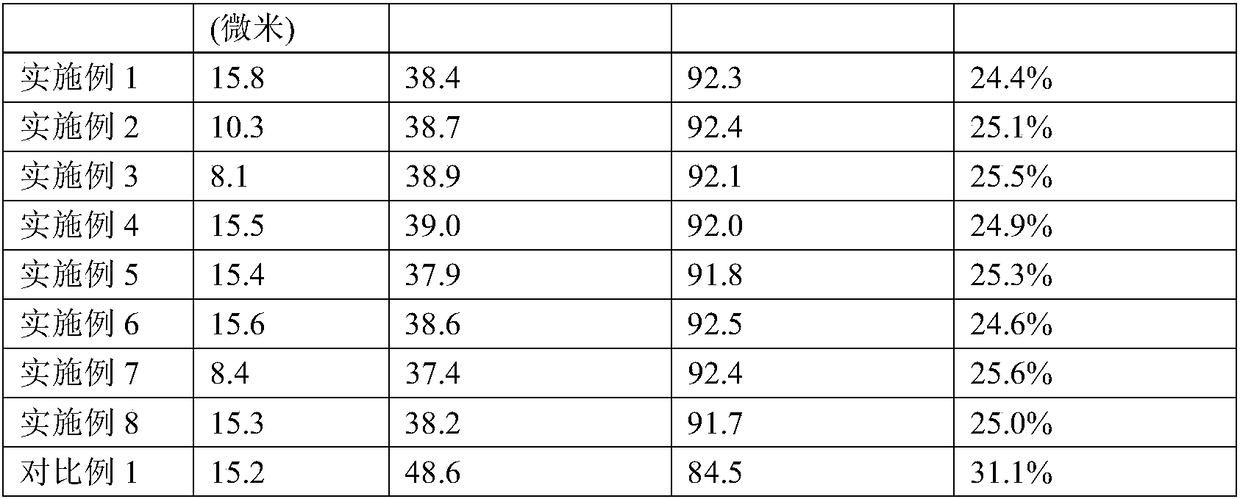

[0063] Spherical natural graphite (with an average particle size of 15 μm) was subjected to cold isostatic pressing at a pressure of 130 MPa for 5 minutes. The product after isostatic pressing is crushed to the approximate particle size of the raw material, and classified. Then according to the mass ratio of 85:15, put the graded samples and coal tar pitch (softening point is 110°C) into the stirring heater and stir for 10 minutes, then raise the temperature to 300°C and stir for 30 minutes at a constant temperature, and then carbonize at 1200°C , to obtain natural graphite-based modified composite anode materials.

[0064] Electrochemical performance test:

[0065] The natural graphite-based composite material obtained in Example 1 is used as the negative electrode active material, after being uniformly mixed according to the mass ratio of active material: CMC:SBR=96.5:1.5:2, coated on the copper foil current collector, and dried to obtain the negative electrode A spare pie...

Embodiment 2

[0071] Spherical natural graphite (with an average particle size of 10 μm) was subjected to cold isostatic pressing at a pressure of 100 MPa for 5 minutes. The product after isostatic pressing is crushed to the approximate particle size of the raw material, and classified. Then, according to the mass ratio of 60:40, put the graded samples and coal tar pitch (softening point is 110°C) into the stirring heater and stir for 10 minutes, then raise the temperature to 300°C and stir for 30 minutes at a constant temperature, and then carbonize at 1200°C , to obtain natural graphite-based modified composite anode materials.

[0072] The same method as in Example 1 was used to prepare negative electrodes, assemble button batteries and finished batteries, and perform performance tests. The obtained cycle performance and electrode expansion rate are listed in Table 1.

[0073] Adopt the same method as Example 1 to carry out XRD test, and the obtained results are listed in Table 1.

Embodiment 3

[0075] Spherical natural graphite (average particle size 8 μm) was subjected to cold isostatic pressing at a pressure of 80 MPa for 5 minutes. The product after isostatic pressing is crushed to the approximate particle size of the raw material, and classified. Afterwards, according to the mass ratio of 90:10, put the graded samples and coal tar pitch (softening point is 110°C) into the stirring heater and stir for 10 minutes, then raise the temperature to 300°C and stir for 30 minutes at a constant temperature, and then carbonize at 1100°C , to obtain natural graphite-based modified composite anode materials.

[0076] The same method as in Example 1 was used to prepare negative electrodes, assemble button batteries and finished batteries, and perform performance tests. The obtained cycle performance and electrode expansion rate are listed in Table 1.

[0077] Adopt the same method as Example 1 to carry out XRD test, and the obtained results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com