Bedstead positioning device and welding method thereof

A technology of positioning device and bed frame, which is applied in the direction of welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of affecting welding quality, poor positioning and overlapping effects, etc., achieve strong practicability, great market promotion value, and improve welding Efficiency and effectiveness of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

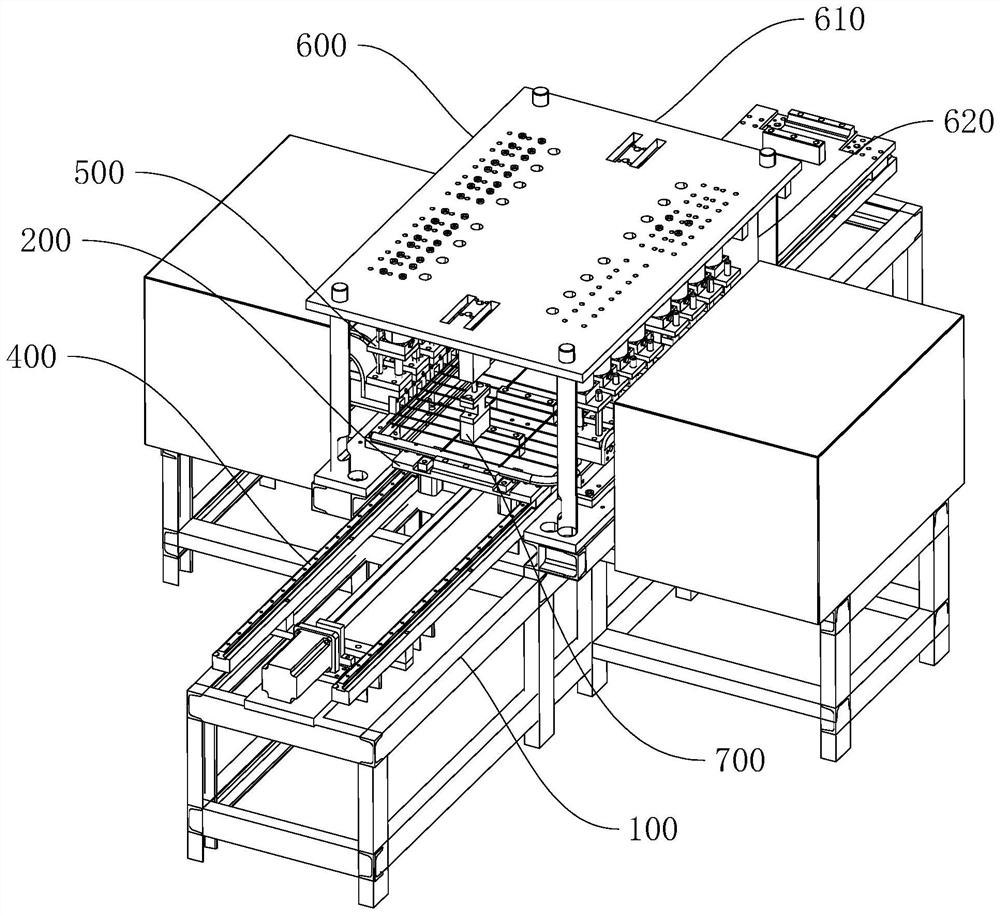

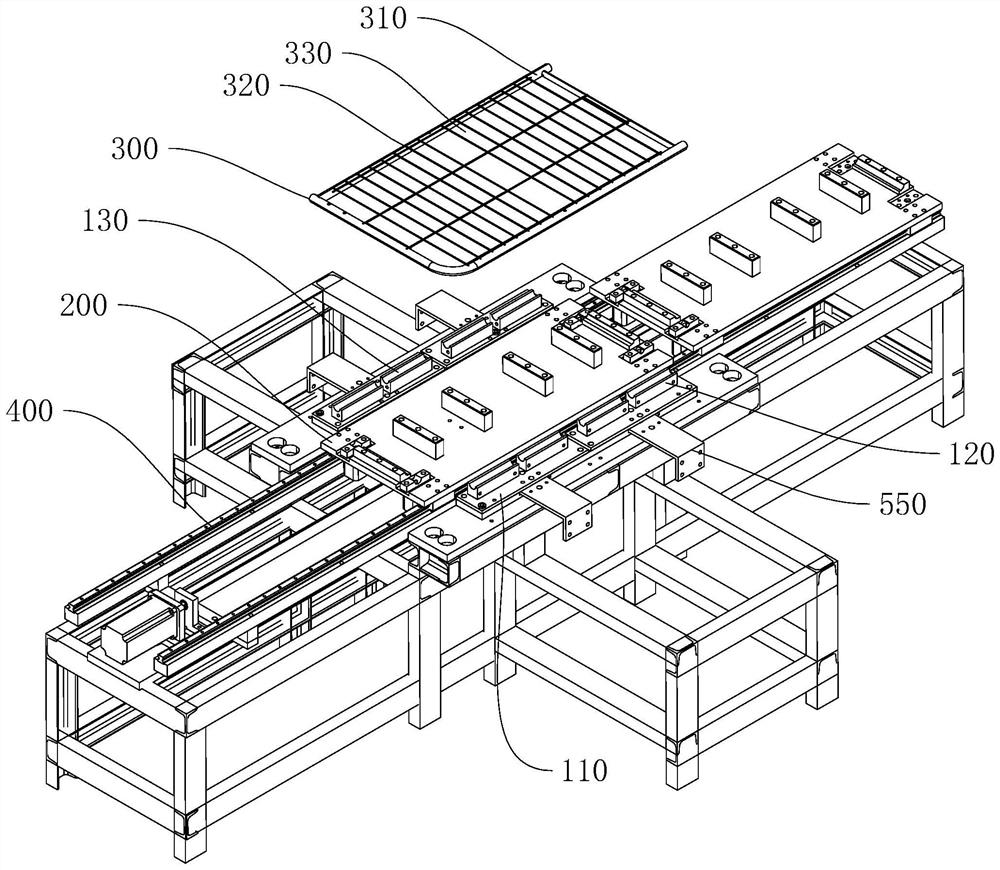

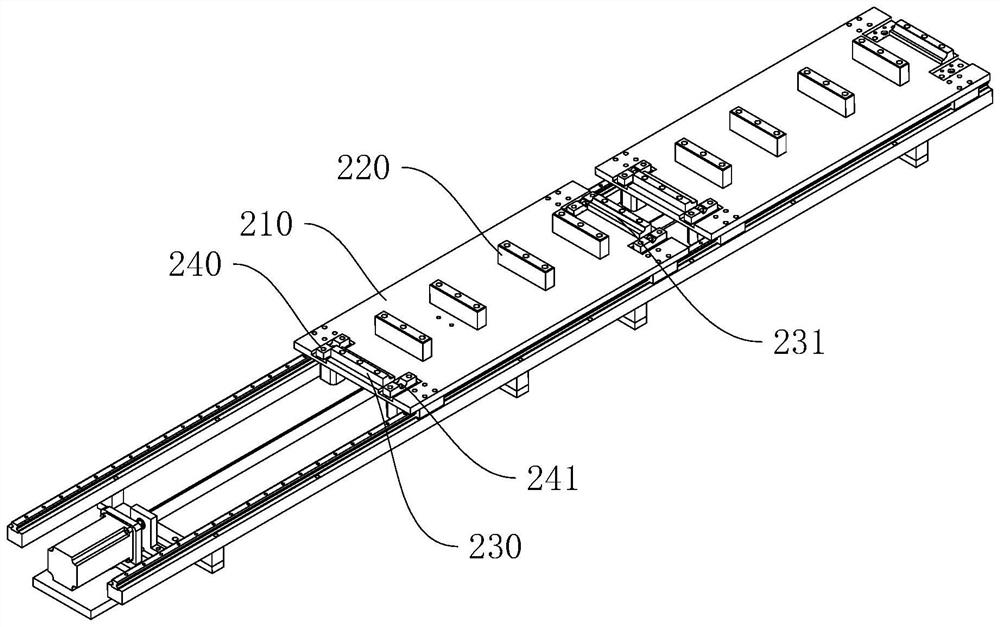

[0057] Embodiment 1: a bed frame positioning device, see figure 1 and figure 2 , including a frame 100, a positioning mechanism 200 and a welding mechanism 500. The frame 100 is provided with a set of sliding mechanisms 400. The sliding mechanism 400 is correspondingly installed with a positioning mechanism 200. The welding mechanism 500 is arranged on both sides of the middle of the frame 100. , and the stable installation of the welding mechanism 500 is realized by setting the connecting plate 550 to be fixedly connected with the frame 100 , and the positioning mechanism 200 is used for positioning and placing the bed frame assembly 300 . The bed frame assembly 300 is a square structure, including an outer frame 310 and a mesh frame assembly 320, the outer frame 310 is composed of four circular tubes connected end to end, and the mesh frame assembly 320 is formed by a plurality of iron wires welded alternately to form a mesh with an array mesh port 330. , the mesh port 330...

Embodiment 2

[0063] In order to ensure the stability of the welding telescopic member 540 during expansion and contraction, the welding telescopic member 540 is further provided with a telescopic guide post 560 , and the welding head 530 is correspondingly provided with a through hole adapted to the telescopic guide post 560 . When the welding telescopic piece 540 is in motion, the linear positioning of the telescopic guide post 560 is used to make the welding telescopic piece 540 more stable when it moves. In the embodiment of the present application, the welding telescopic element 540 adopts a telescopic cylinder, and other telescopic mechanisms can also be used to control the welding head 530 to realize welding. see Figure 5 , in order to fully abut the grid assembly 320 and the outer frame 310, the bottom of the fixing plate 610 is provided with a pre-compression member 700 for pre-compressing the bed frame assembly 300, and the pre-compression member 700 includes a pre-compression te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com