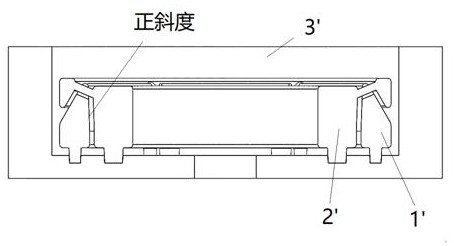

Tool for combining reverse-inclination resin sand mold core and combining and assembling method of tool

A technology of backslope and resin sand, which is applied in the direction of cores, molds, mold components, etc., can solve the problem that two cores cannot be loaded, and achieve the effect of high combination accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method of the present invention will be described below through specific embodiments, but the present invention is not limited thereto, and any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention shall be included in the scope of the present invention. within the scope of protection.

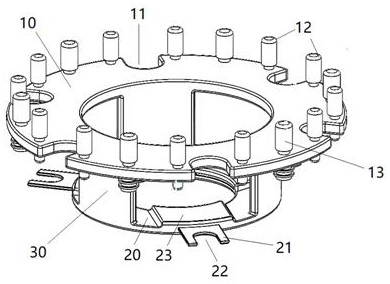

[0032] like Figure 3-4 As shown, the present invention provides a tooling for the combination of reverse slope resin sand cores, which is used to install the first core 1 and the second core 2. The tooling is composed of upper and lower layers, including an upper disc 10 and a lower disc 20 and the support column 30 between them. The diameter of the upper disk 10 is larger than the diameter of the lower disk 20 . The specific size of the diameter of the upper disk 10 and the lower disk 20 can be determined according to the size of the core to be assembled. The distance between the upper disk 10 and the lower disk 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com