Efficient and environment-friendly gravitational dust removal and recovery system for dust in putty powder production process

A production process, gravity dedusting technology, applied in the direction of human health protection, dispersed particle separation, climate change adaptation, etc., can solve the problems of easy clogging, general filtering effect, poor dust removal effect, etc., and achieve the effect of avoiding clogging and filtering burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the description below, a lot of specific details are given to provide a more thorough understanding of the invention. However, for the technical personnel of the art, it is easy to see that the present invention can be implemented without one or more details. In other examples, in order to avoid confusion with the present invention, some technical characteristics of public knowledge in the art have not been described.

[0031] The connection method can adopt existing methods such as bonding, welding, bolt connection, etc., which are subject to actual needs.

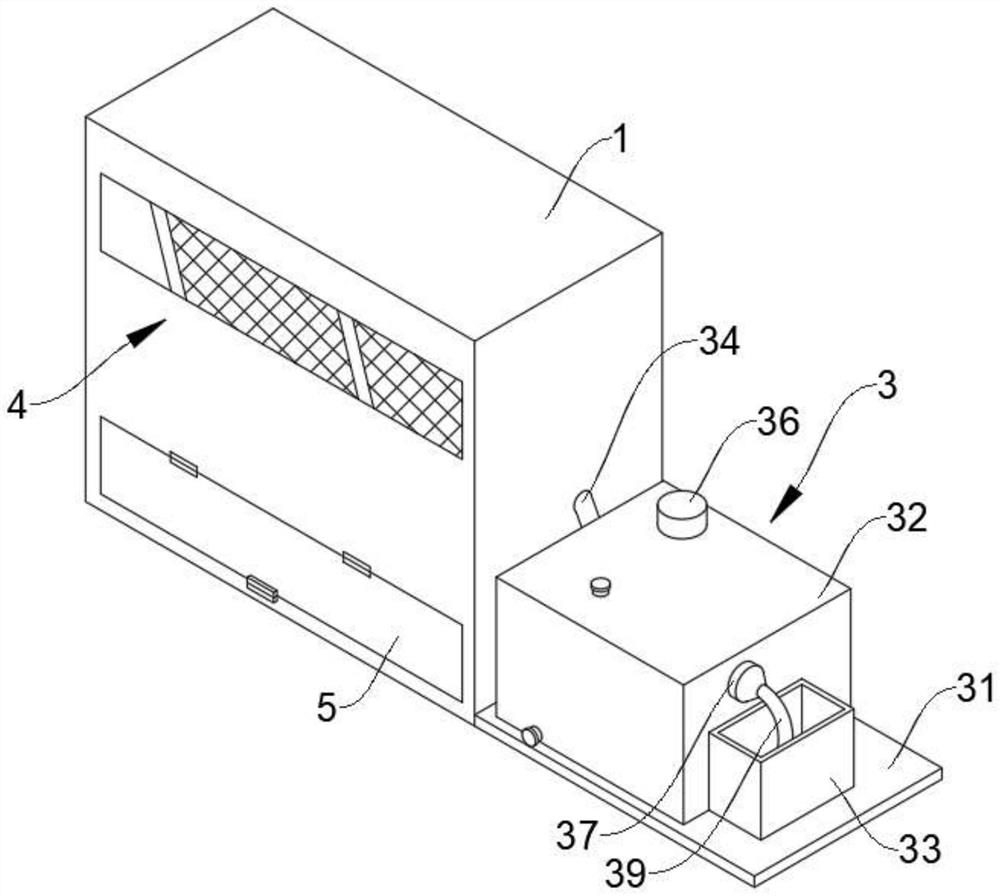

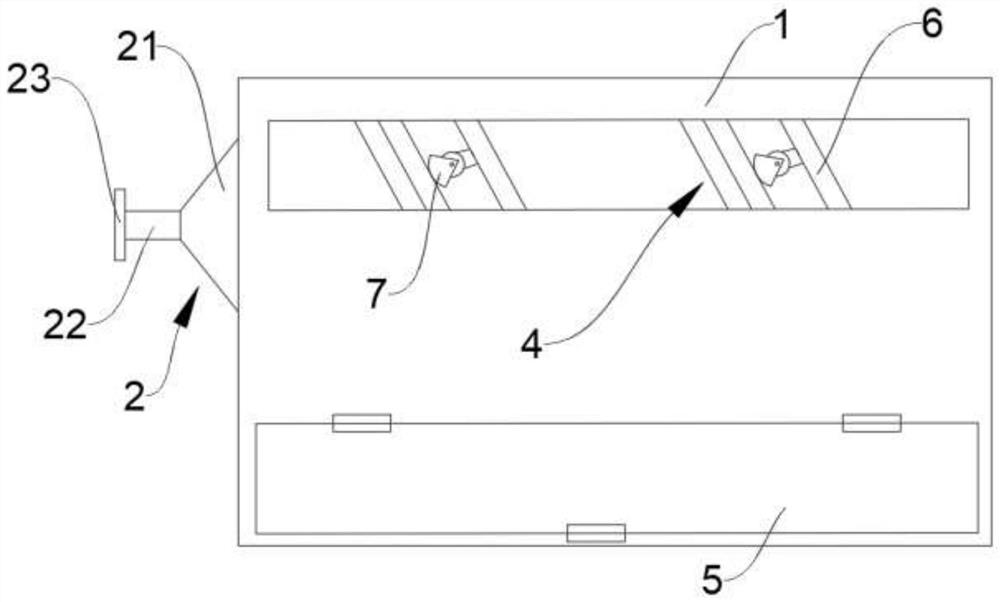

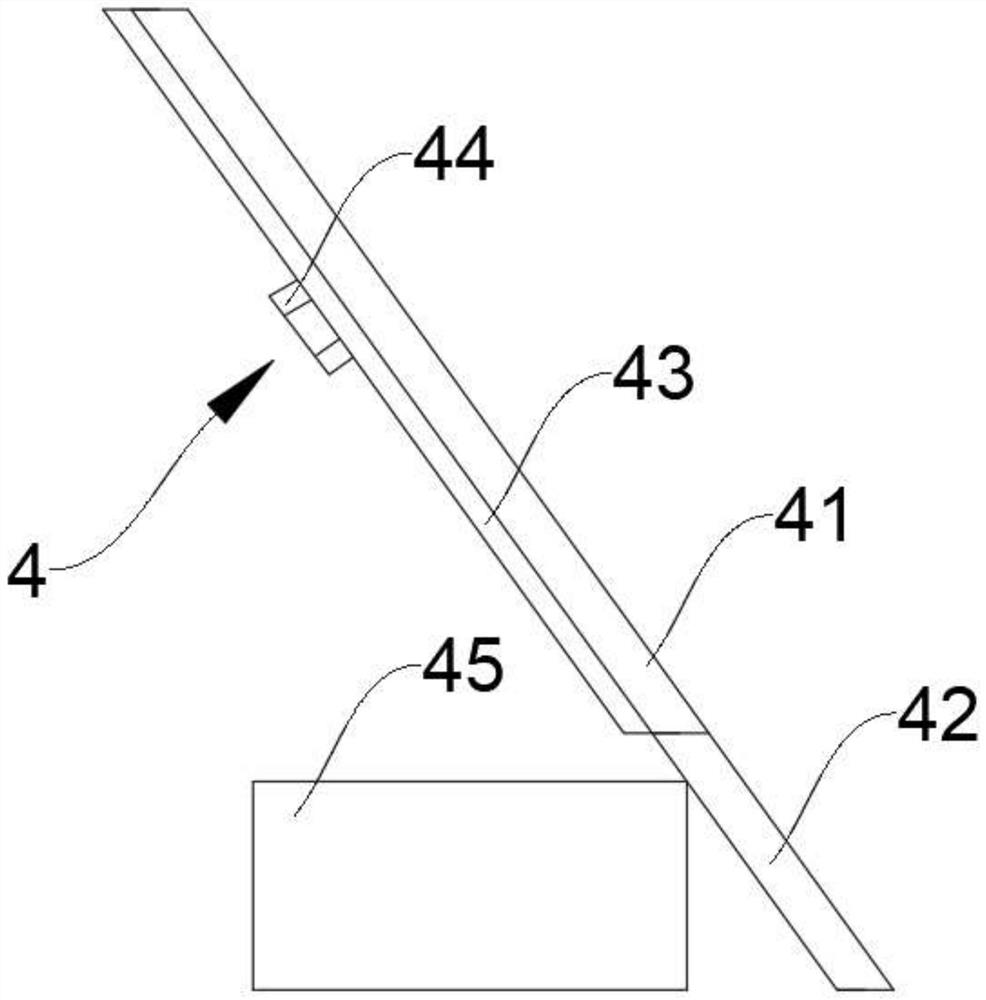

[0032] In order to filter and clean the dust in the air, such as Figure 1 to Figure 5 A kind of putty powder shown in the production process of stuffed powder, high -efficiency and environmental protection gravity dust removal recovery system, including processing box 1, the inner wall of the processing box 1, there are multiple recycling combinations 4, multiple recycling combinations include filter box 41, oblique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com