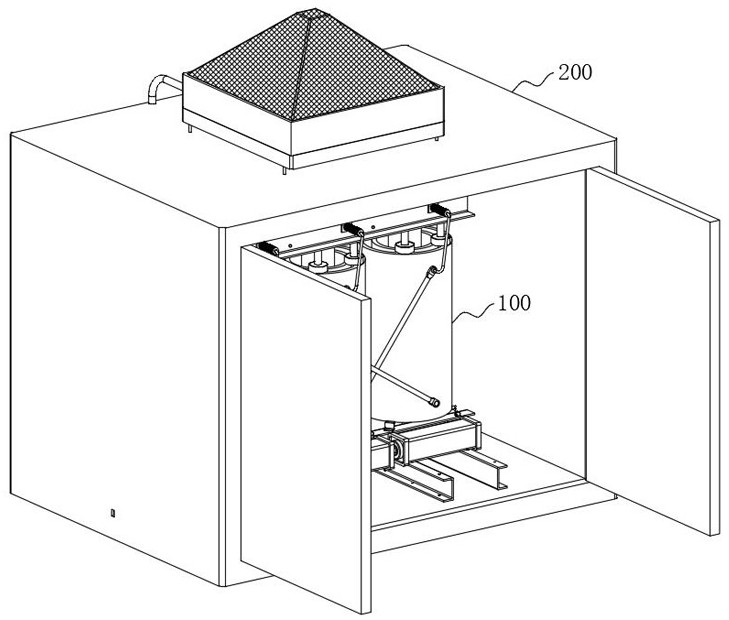

Dry-type high-frequency high-voltage transformer

A high-frequency, high-voltage, transformer technology, applied in the field of transformers, can solve the problem of slowing down the heat dissipation efficiency of dry-type transformers, and achieve the effect of facilitating cooling and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

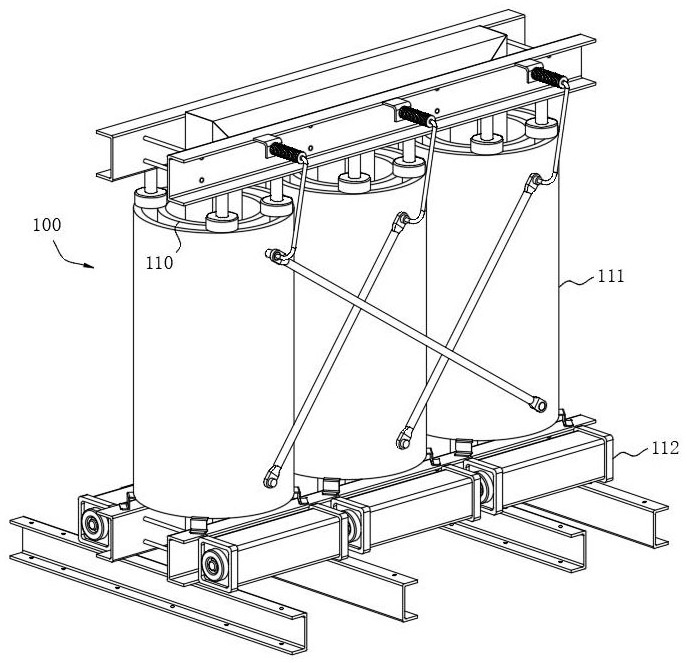

Method used

Image

Examples

no. 2 example

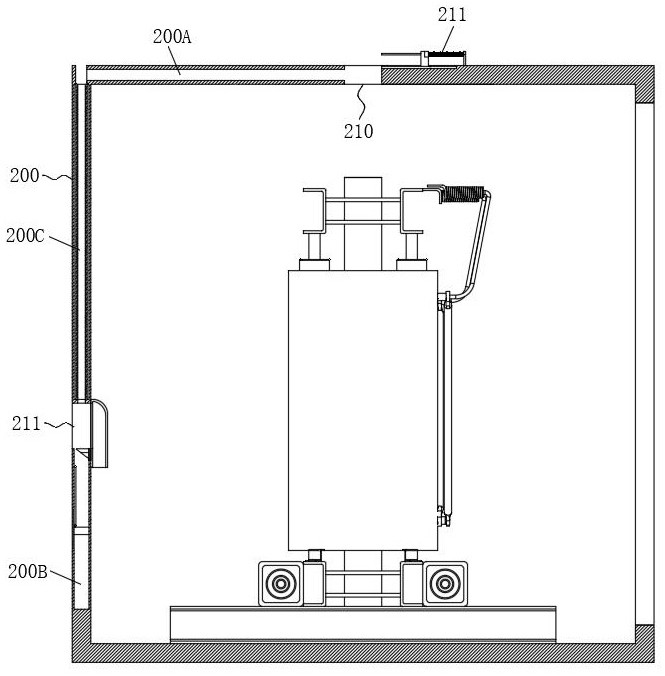

[0052] In the second embodiment, considering that it is easy to encounter wind when it rains, the wind easily blows the rain into the exhaust hole 210 and the sealing member 211, causing the liquid to enter the box 200. For this, please refer to Figure 5 As shown in the figure, a connecting plate 230 is fixedly arranged at the bottom of the protective plate 216, the connecting plate 230 has a ring structure, and a straight rod 231 is disposed at the bottom of the connecting plate 230. A compression spring 232 is arranged between one end of the body 200 and the top inner wall of the box body 200. The rainwater enters the liquid collecting tank, and the guard plate 216 is moved down by gravity, so that the bottom end of the connecting plate 230 is in contact with the top of the box body 200. At this time, the exhaust hole 210 is cut off by the protective plate 216 and the connecting plate 230, and cannot communicate with the outside world, so the gas can only enter the gas deliv...

no. 3 example

[0054] In the third embodiment, considering that the fan 112 blows upwards from the bottom, and the wind becomes hotter during the process of blowing from the bottom to the top, the heat dissipation performance of the top of the transformer body 100 is poor. Therefore, as Figure 8-Figure 11 As shown, the bottom of the liquid storage chamber 200B is fixedly provided with a connection spring 251, the top of the connection spring 251 is provided with a carrier plate 250, the top of the carrier plate 250 is provided with two straight plates 252, and the floating block 214 is located between the two straight plates 252. During the time, the top of the floating block 214 is rotatably connected with the bottom end of the partition plate 215, a gap 253 is formed on the inner wall of the box body 200 on the side of the liquid storage cavity 200B, and a storage cavity 200E is opened on the inner wall of the box body 200 at the bottom of the gap 253. A sealing plate 254 is slidably arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com