B1-level flame-retardant cable

A technology of flame-retardant cables and flame-retardant materials, applied in the direction of insulated cables, flat/ribbon cables, cables, etc., can solve the problem of replacing the entire cable with the core, and achieve the effect of reducing the resistance of the pull-out and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

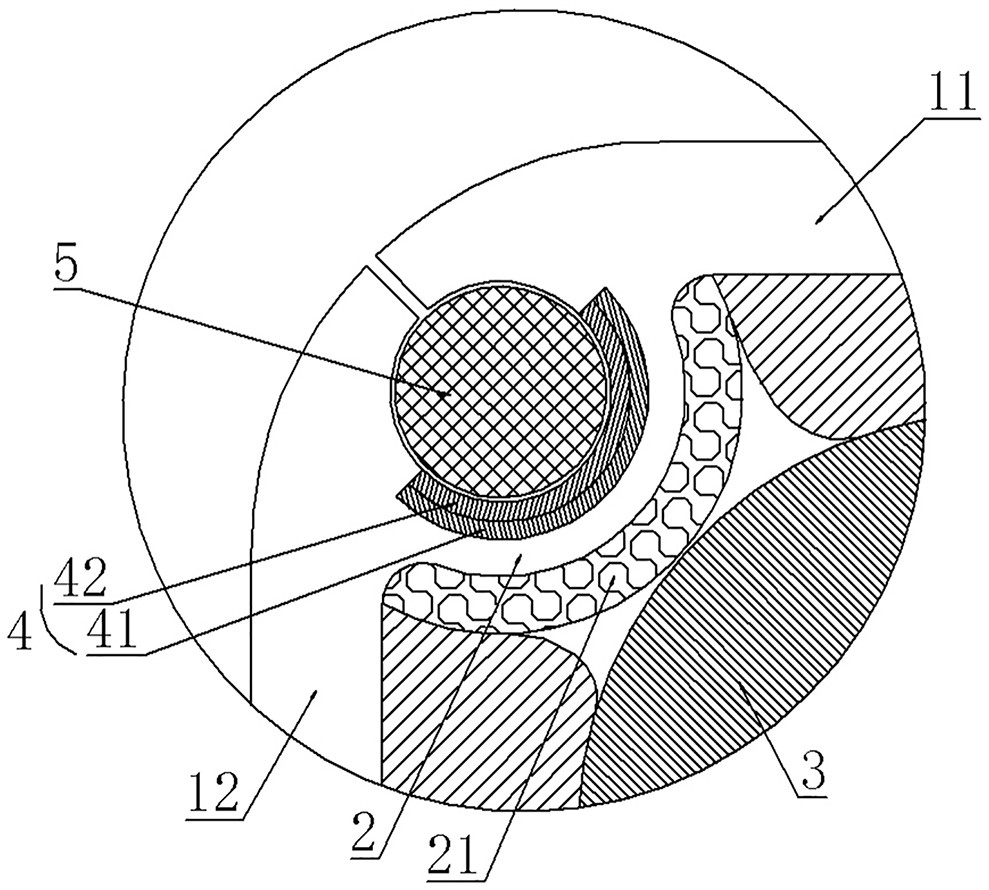

[0044] see figure 2 , as a specific embodiment of the B1-level flame-retardant cable provided in this application, the thermal deformation member 4 includes:

[0045] The passive layer 41 is arranged along the inner wall of the inwardly curved portion 2;

[0046] The active layer 42 is stacked on the side of the passive layer 41 facing away from the inner wall of the inwardly curved portion 2, and is thermally connected to the tensile cord 5, and the corresponding ends of the passive layer 41 and the active layer 42 are fixed, and the thermal expansion coefficient of the active layer 42 greater than the thermal expansion coefficient of the passive layer 41;

[0047] The tensile cord 5 is attached to the active layer 42 .

[0048]In the specific implementation, initially, the thermal deformation member 4 is attached to the inner wall of the inner curved portion 2 in an arc shape; when the thermal deformation member 4 is heated, the elongation of the active layer 42 is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com