Material-structure integrated optimization method for steel-aluminum hybrid frame

An optimization method and frame technology, applied in multi-objective optimization, design optimization/simulation, constraint-based CAD, etc., to achieve high reliability and applicability, save development costs and development cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

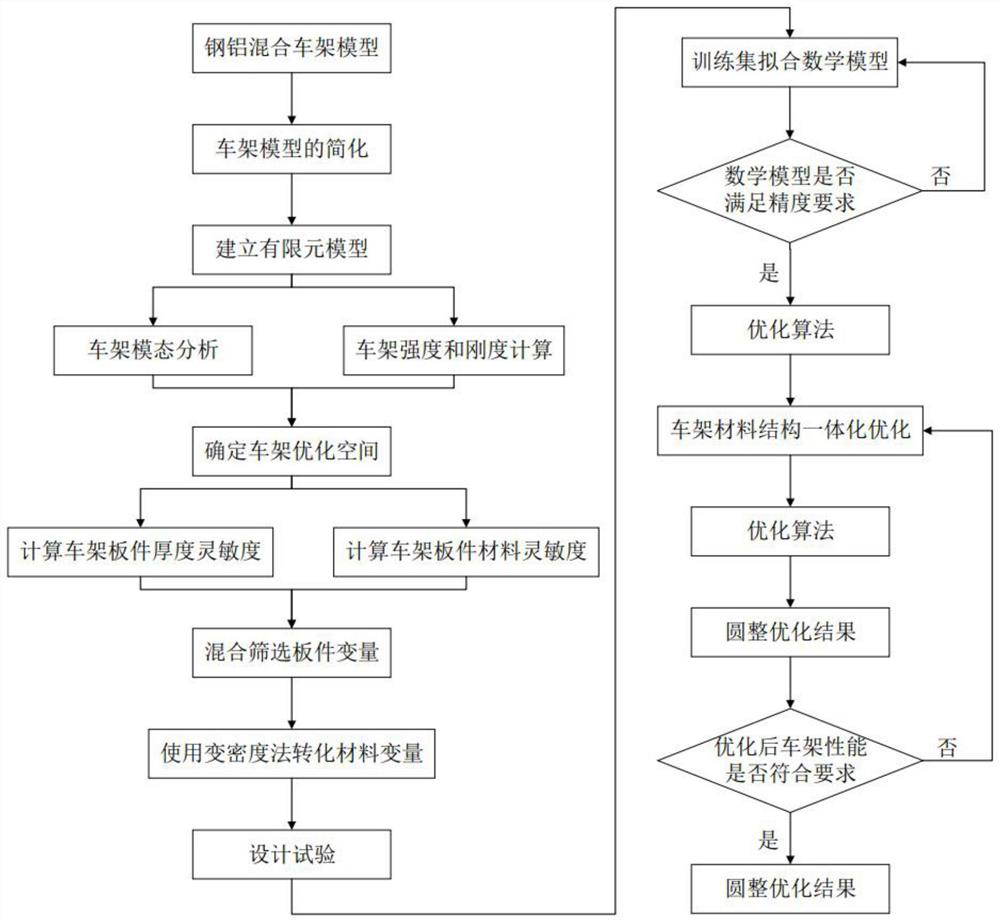

[0046] like figure 1 As shown, a material-structure integration optimization method for a steel-aluminum hybrid frame includes the following steps:

[0047] Step 1: Optimize the establishment of the object model;

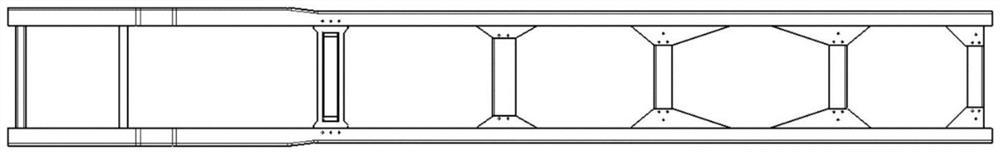

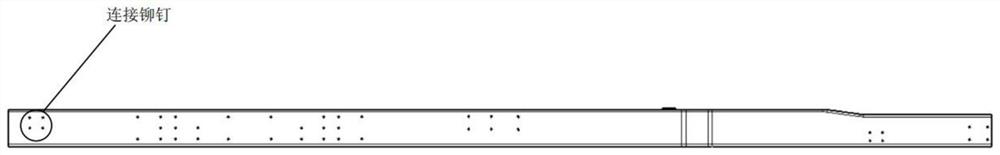

[0048] A frame is mainly composed of longitudinal beams, cross beams, ingot beams, and shaped column beams. After the model is simplified, a simplified 3D model of the frame is established in Catia, such as figure 2 and image 3 shown. The main materials of the frame plates are Q345B and high-strength aluminum. Check the mechanical design manual to know that the main performance parameters are: The density of Q345B is 7.9×10 -6 kg / mm 3 , the Poisson’s ratio is 0.3, and the elastic modulus is 2.1×10 5 MPa, the yield strength is 345MPa; the material properties of high-strength aluminum are: the density is 2.7×10 -6 kg / mm 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com