Small-sized double-rotor fault simulation experiment table and fault diagnosis simulation method

A fault simulation and test bench technology, which is applied in the field of rubbing fault simulation experiments, can solve problems such as inconvenient maintenance and difficult disassembly, and achieve the effect of complete functions, compact structure, and protection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The content of the present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

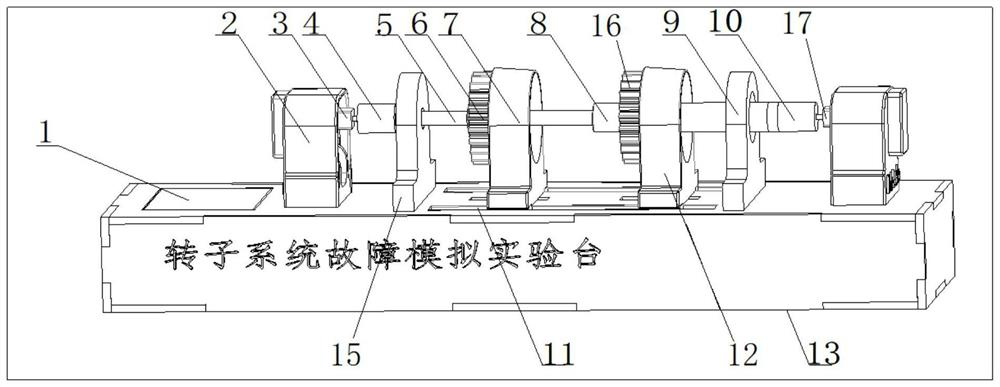

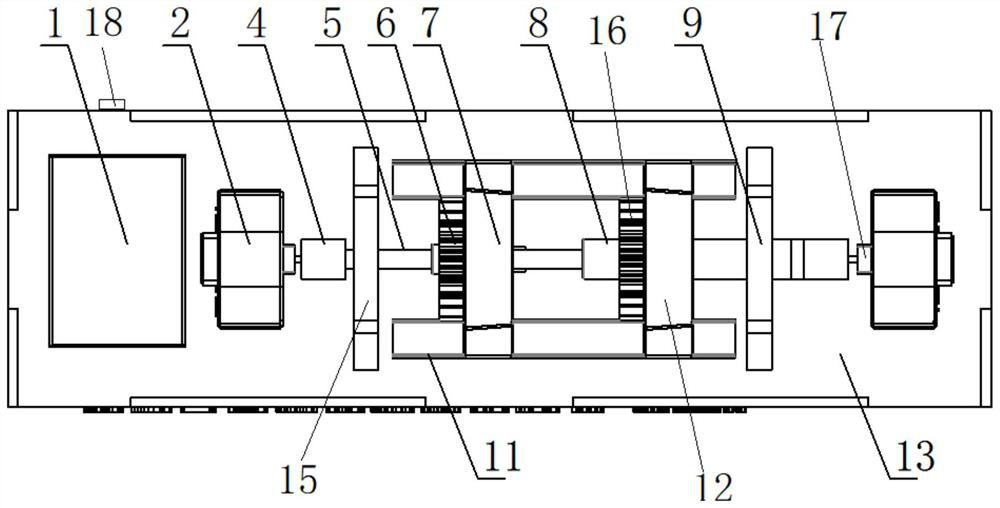

[0085] like Figure 1-Figure 4 , Image 6 As shown in the figure, a small double-rotor fault simulation test bench includes the base of the test bench and two other main components. Among them, the first part is the upper mechanical part, namely the mechanical simulation module; the second part is the lower embedded control part.

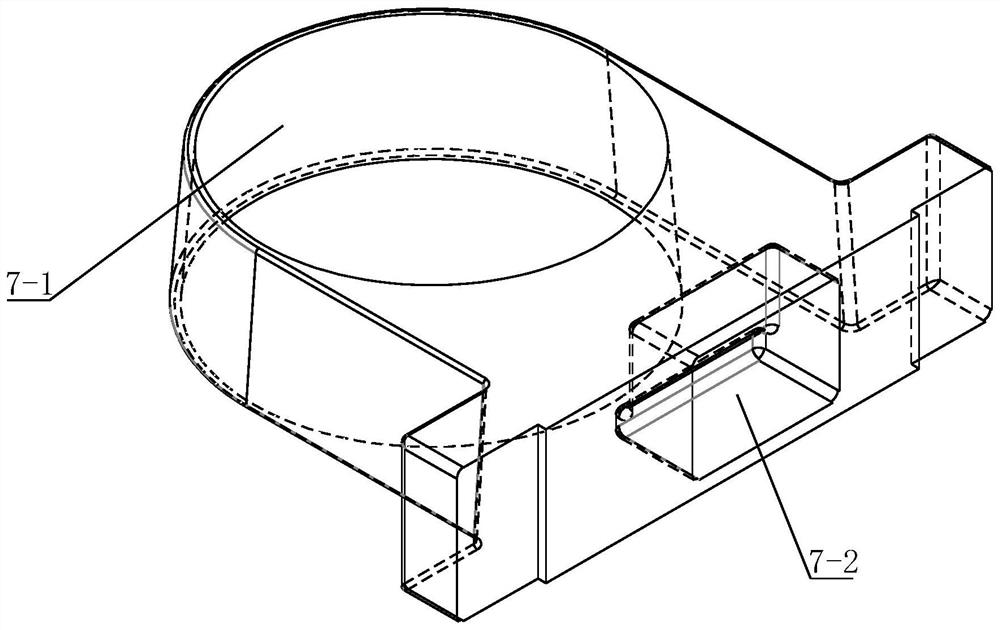

[0086] The mechanical simulation module includes two three-degree-of-freedom adjustable motor bases, a motor with an encoder installed on the motor base, and two coaxial rotors (one of which is directly installed on the shaft and connected to the motor through a coupling). , one of the motors is fixed on the sleeve, the inside of the sleeve is mounted on the rotating shaft by two bearings, and one end of the sleeve is connected with the other motor by a coupling, this structure can make the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com