Device and method for measuring roughness of laminated surface of precast concrete member

A technology of prefabricated concrete and measuring devices, applied in measuring devices, measuring inclination, using optical devices, etc., can solve problems such as the lack of methods for determining the reference plane, and achieve comprehensive measurement and evaluation methods, simple test methods, and reasonable evaluation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings.

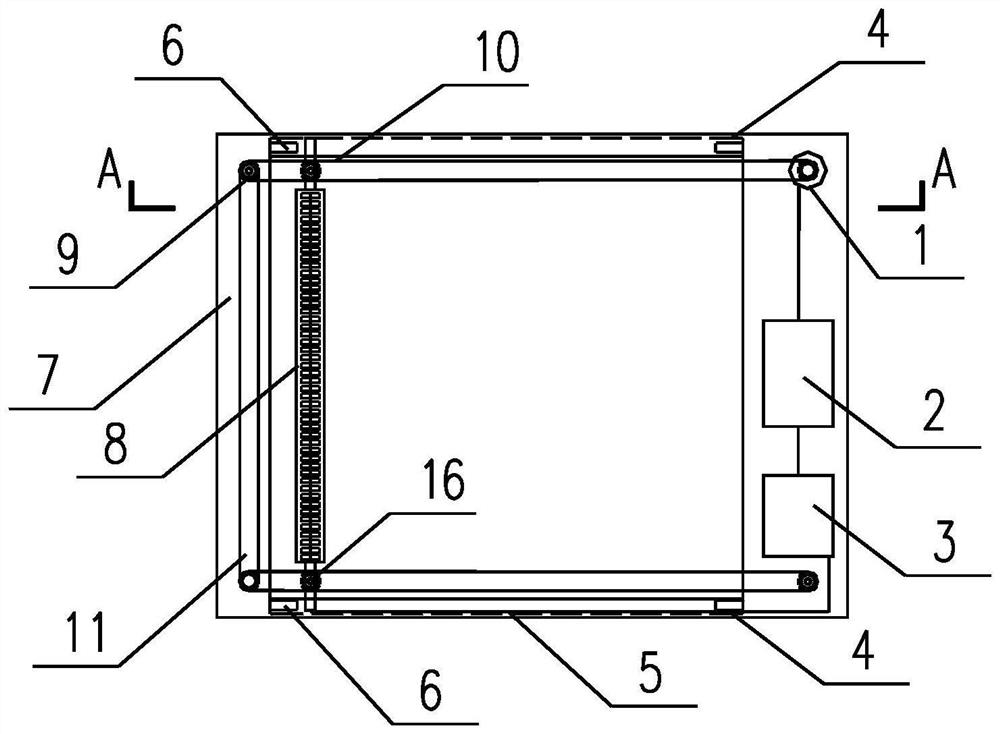

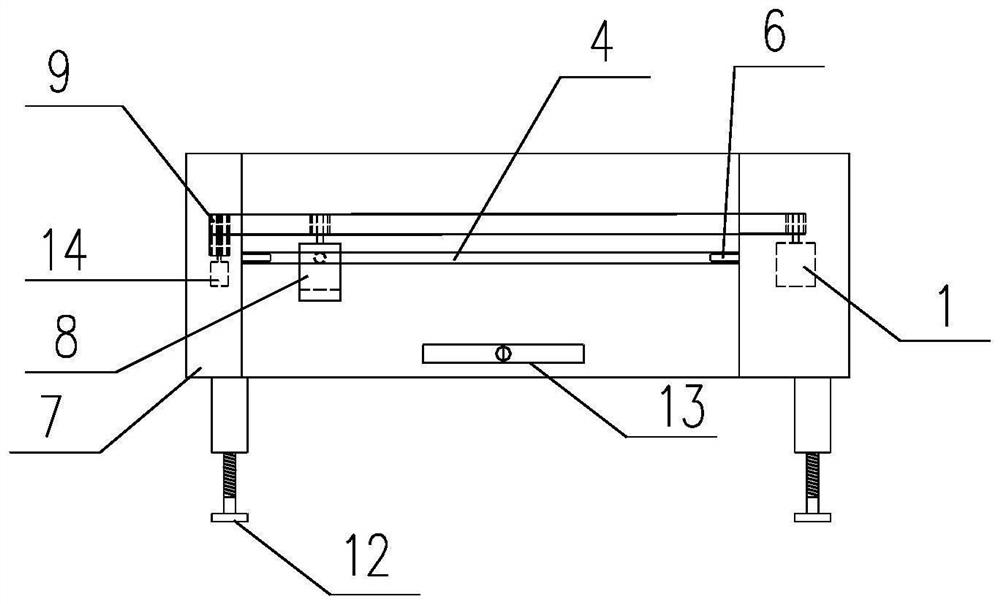

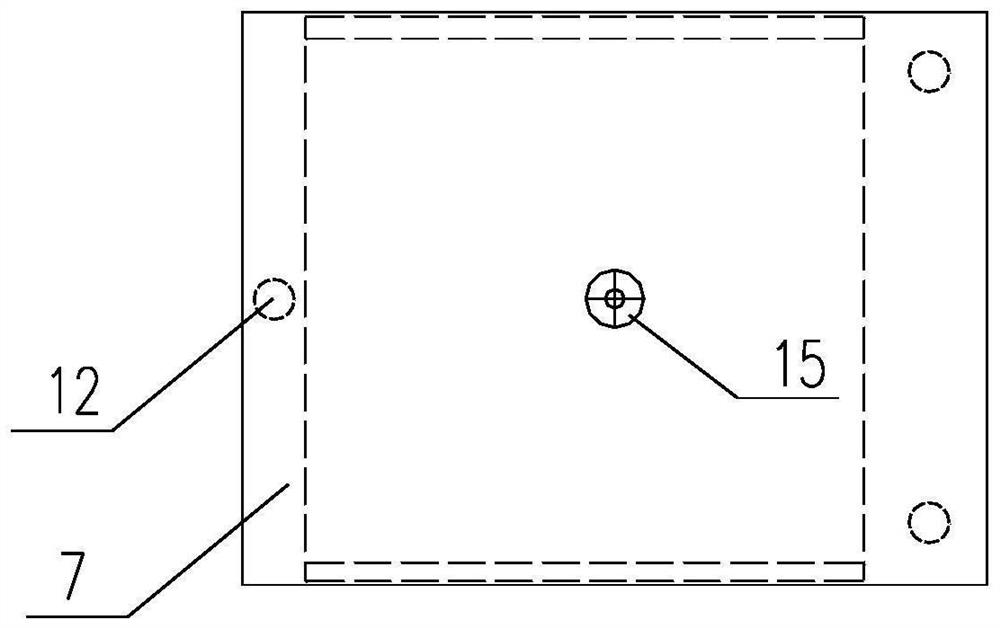

[0051] refer to Figure 1 to Figure 4 , a measuring device for the roughness of the superimposed surface of prefabricated concrete components, including a frame 7, a scanning unit 8, a stepping motor 1, an information acquisition module 3 and a power supply and a controller module 2, the top of the frame 7 is provided with a circle The level device 15 is used to reflect whether the rack is placed horizontally; the inside of the rack 7 is distributed with a stepping motor 1, an information acquisition module 3 and a power supply and a controller module 2, and the inner cavity of the rack 1 is provided with a scanning Unit 8, two guide grooves 4 of the same height are distributed on both sides of the frame perpendicular to the scanning unit 8, and limiters 6 are respectively provided at both ends of the guide groove 4, and the stepping motor 1 drives the scanning unit al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com