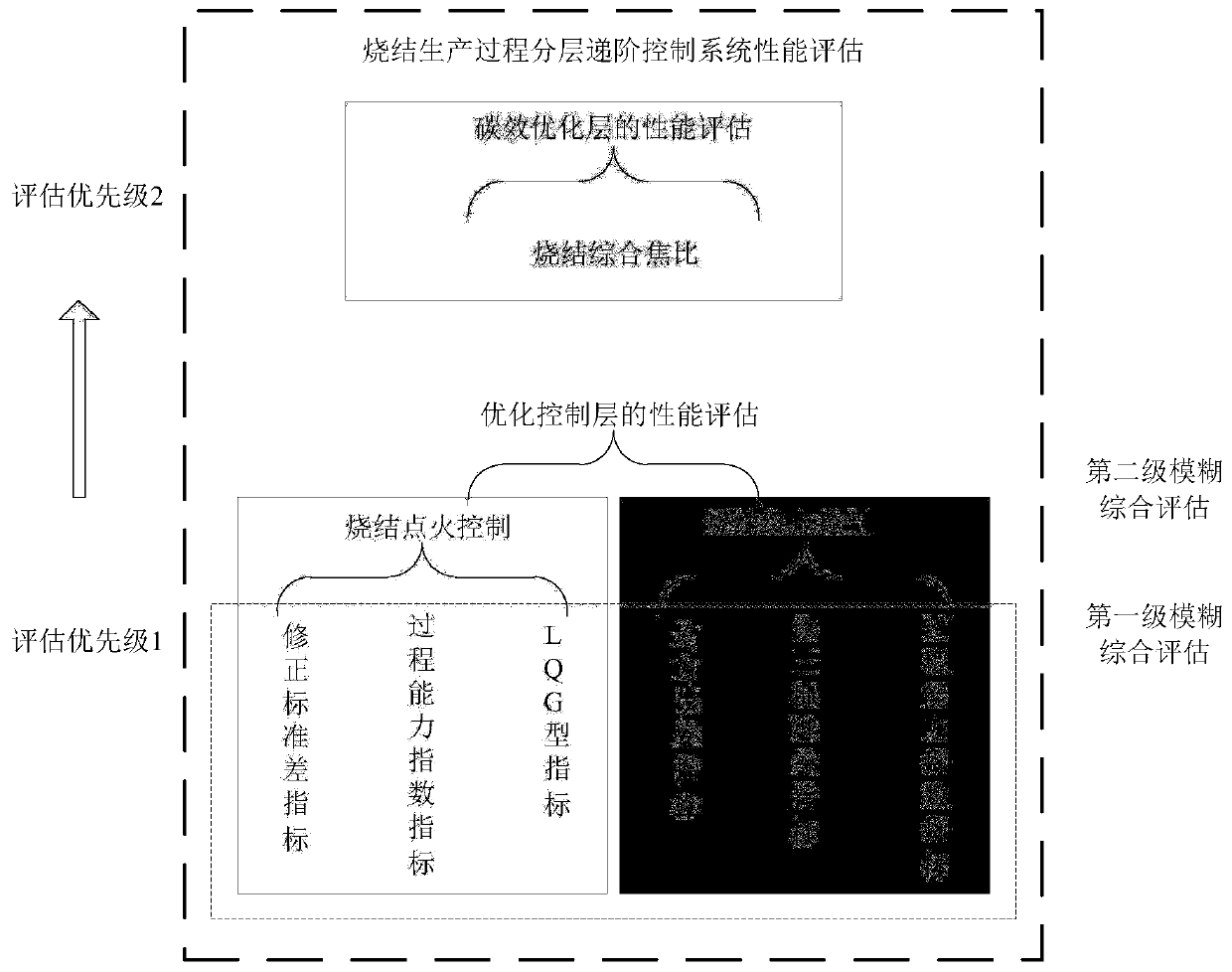

A performance evaluation method of sintering production process based on fuzzy synthesis

A production process, fuzzy synthesis technology, applied in the direction of instruments, adaptive control, control/regulation system, etc., can solve problems such as waste of blast furnace gas, coke oven gas and coke powder, economic losses, wrong setting values, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

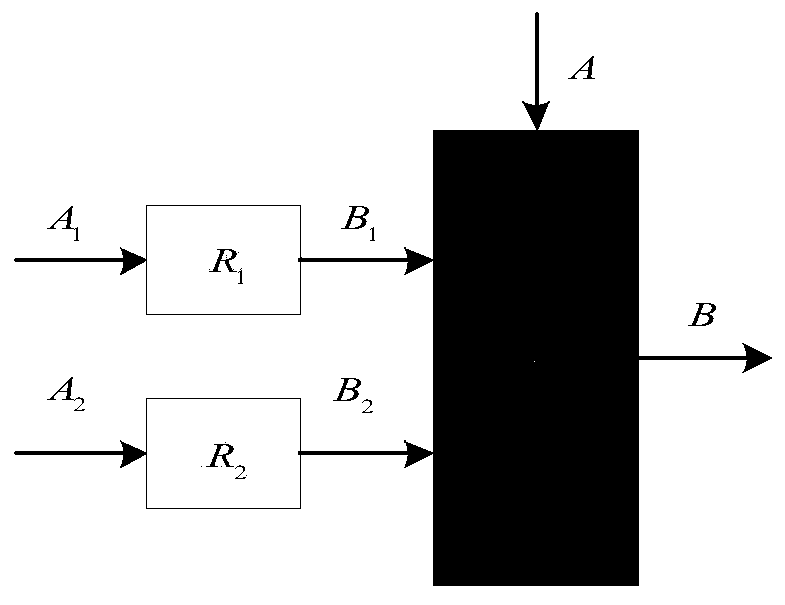

Method used

Image

Examples

Embodiment 2

[0109] Embodiments of the present invention provide a method for evaluating the performance of a sintering production process based on fuzzy synthesis, comprising the following steps:

[0110] (1) Establish an evaluation factor set for optimizing the control layer, that is, collect historical data of sintering production to obtain original sample data and establish a sample database;

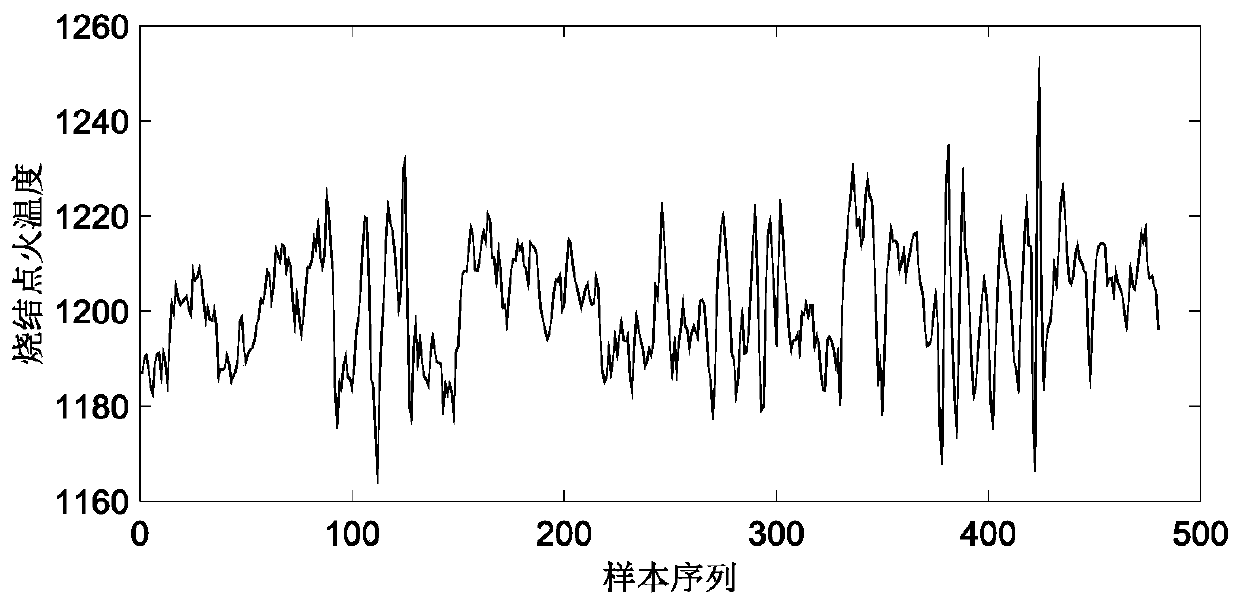

[0111] The historical data of sintering production is stored in the local database of the industrial computer in the operating room in the form of daily reports. According to the data in the daily reports, the historical data of ignition temperature and sintering end position for one month are collected to form the original sample data. The evaluation period is set to 10 days , the data average value of every half hour is used as a set of data, and a total of 480 sets of evaluation data are obtained, and a sample database is established with these data; and the formulas (1) to (6) of Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com