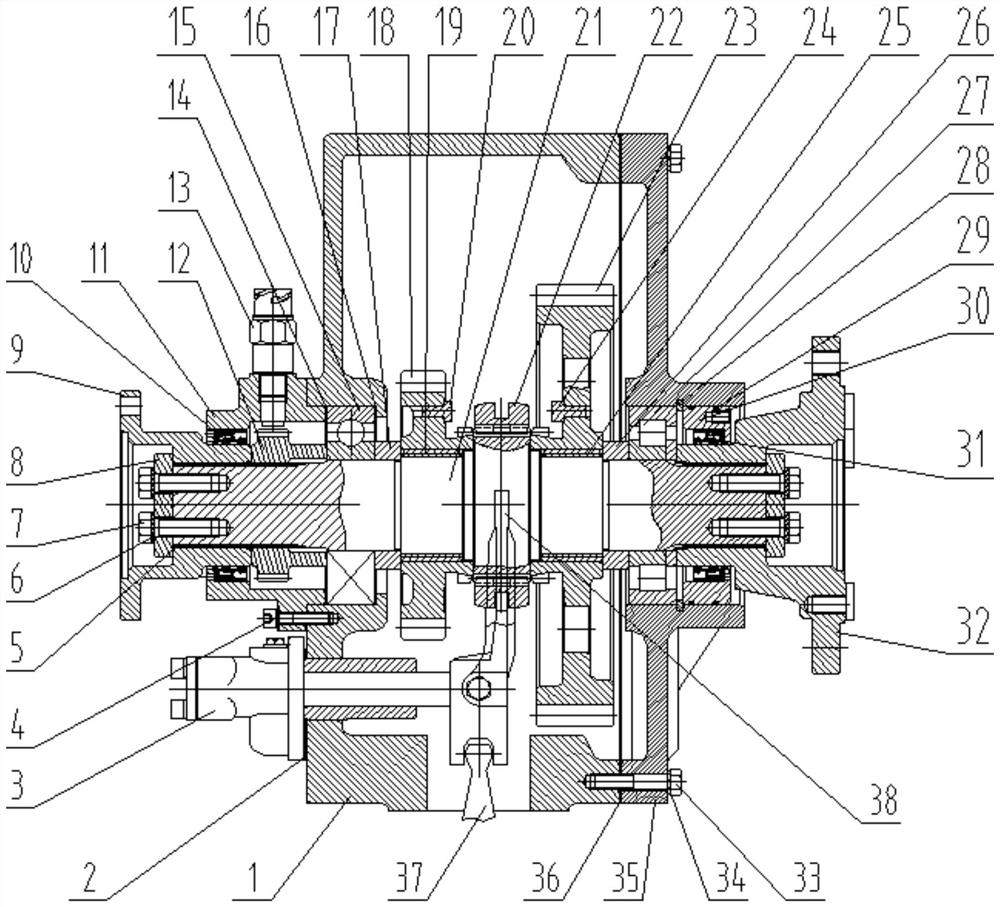

Engineering machinery gearbox output shaft assembly and adjusting method

A technology for output shaft assembly and construction machinery, which is applied in the direction of mechanical equipment, mechanical control devices, transmission boxes, etc., and can solve the problems of gear disengagement, accelerated tooth wear, and fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The adjustment method is as follows:

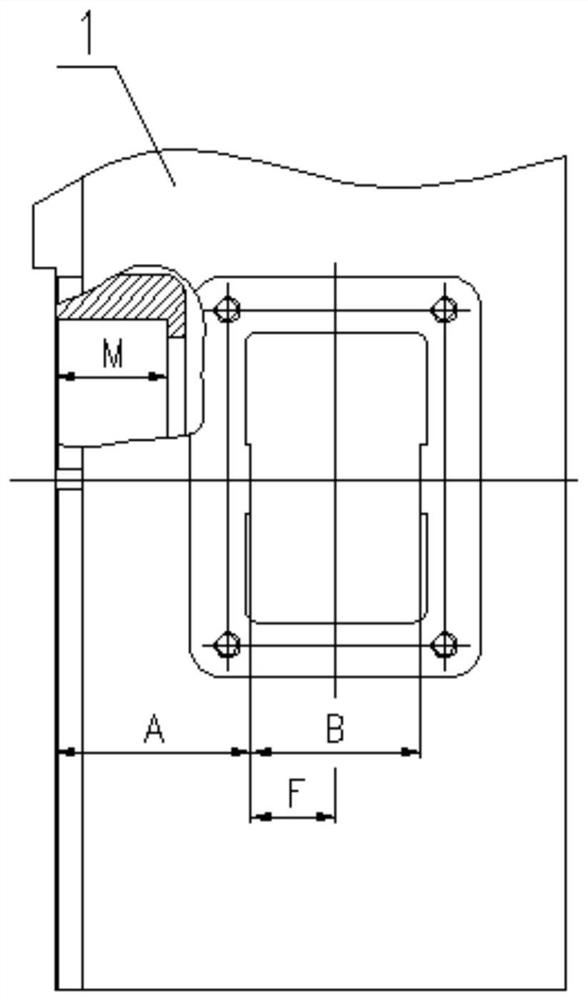

[0039] S1: The distance from the left limit surface of the window of box 1 to the installation surface of shift fork assembly 3 is A=78.86mm;

[0040] S2: The distance between the two limit surfaces of the measurement box 1 window is B=67.98mm;

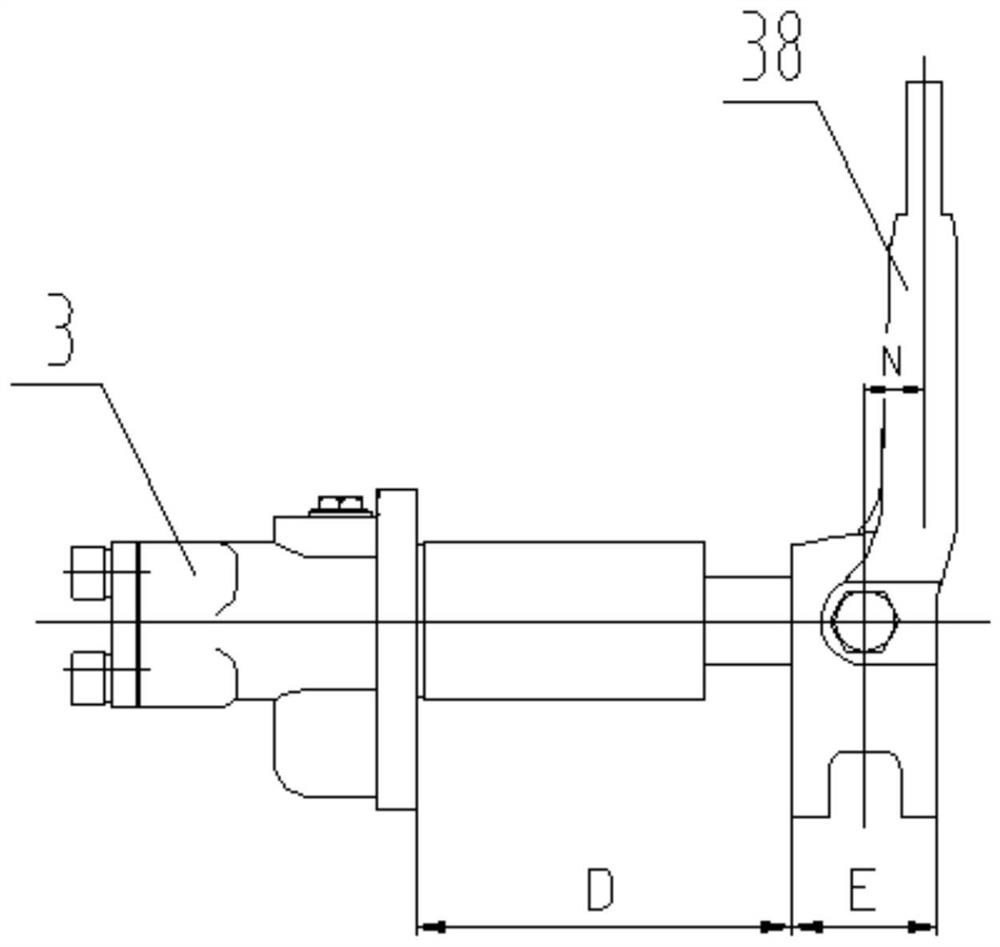

[0041] S3: Adjust the shift fork 38 of the shift fork assembly 3 to the neutral position, and measure the distance from the end face of the shift fork bracket in the shift fork assembly 3 to the limit surface on the left side of the shift fork 38 as D=94.62 mm;

[0042] S4: Measure the thickness of the two outer limit surfaces of the U-shaped head of the shift fork 38 to be E=37.06mm;

[0043] S5: Calculate the distance from the two outer sides of the U-shaped head of the shift fork 38 to the left and right limit surfaces of the box 1 window as F=(B-E) / 2=15.46mm;

[0044] S6: The shift fork 38 is adjusted to the center of the two limit planes of the window of the box body 1: the thickne...

Embodiment 2

[0052] The adjustment method is as follows:

[0053] S1: The distance from the left limit surface of the window of box 1 to the installation surface of shift fork assembly 3 is A=78.92mm;

[0054] S2: The distance between the two limit surfaces of the measurement box 1 window is B=68.06mm;

[0055] S3: Adjust the shift fork 38 of the shift fork assembly 3 to the neutral position, and measure the distance from the end face of the shift fork bracket in the shift fork assembly 3 to the limit surface on the left side of the shift fork 38 as D=94.96 mm;

[0056] S4: Measure the thickness of the two outer limit surfaces of the U-shaped head of the shift fork 38 to be E=36.98mm;

[0057] S5: Calculate the distance from the two outer sides of the U-shaped head of the shift fork 38 to the left and right limit surfaces of the box 1 window as F=(B-E) / 2=15.54mm;

[0058] S6: The shift fork 38 is adjusted to the center of the two limit planes of the window of the box body 1: the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com