Garbage processor and control method thereof

A technology of garbage disposer and control method, which is applied in the direction of instruments, scientific instruments, buildings, etc., which can solve the problems of easy deposition and blockage of kitchen waste, and achieve the effect of simple and flexible switching method and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

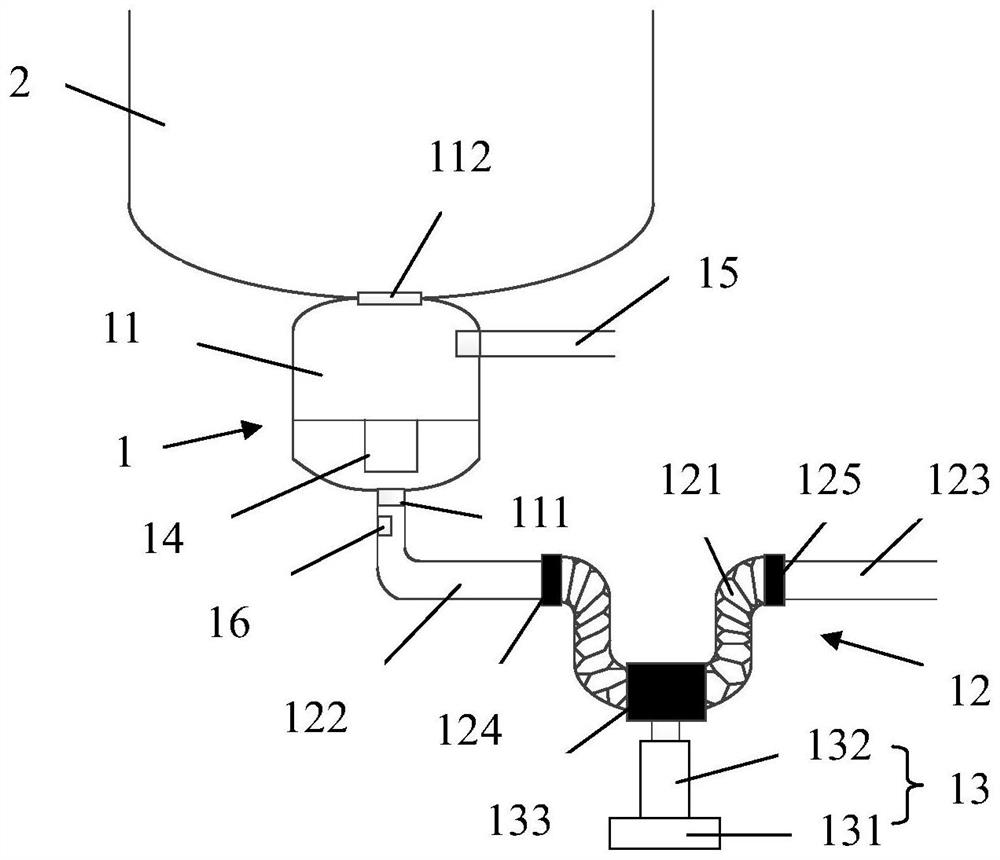

[0055] like figure 1 and figure 2 As shown, this embodiment provides a garbage disposer 1, including a garbage disposal cavity 11, a downpipe 12 and a drive mechanism 13, the bottom of the garbage disposal cavity 11 has a garbage outlet 111, and the top of the garbage disposal 1 has a garbage outlet 111. There is a garbage inlet 112 suitable for connecting with the water outlet of the water tank 2. The kitchen waste in the water tank 2 can enter the garbage disposal cavity 11 through the water outlet and the garbage inlet 112, and be ground and pulverized by the grinding component and then discharged. to the sewer pipe 12.

[0056] Further, the sewer pipe 12 is connected to the garbage outlet 111, one end of the sewer pipe 12 is connected to the garbage outlet 111, and the other end is connected to the external sewer pipe, which is suitable for discharging the ground kitchen waste to Urban sewage recycling system.

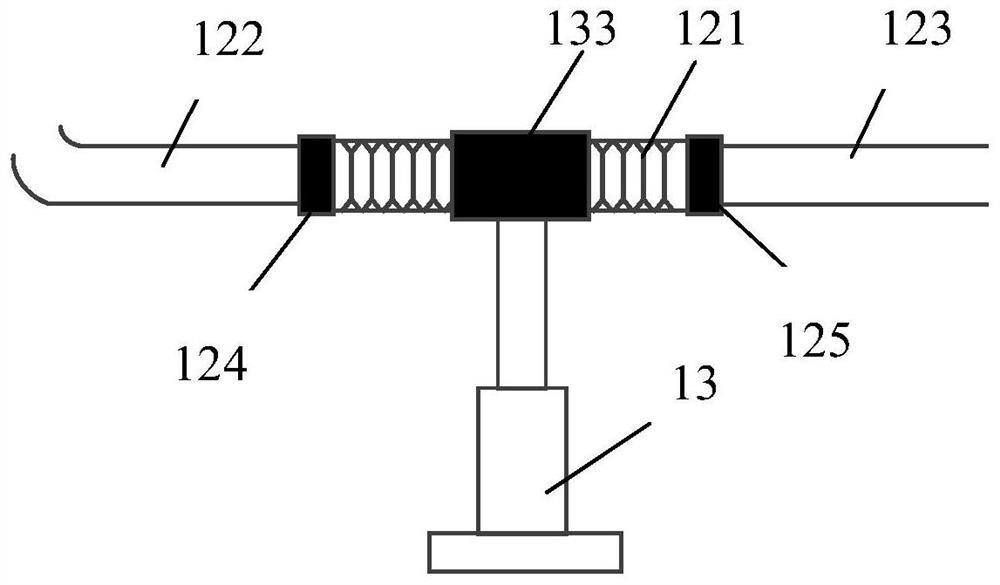

[0057] In this embodiment, the downpipe 12 includes at le...

Embodiment 2

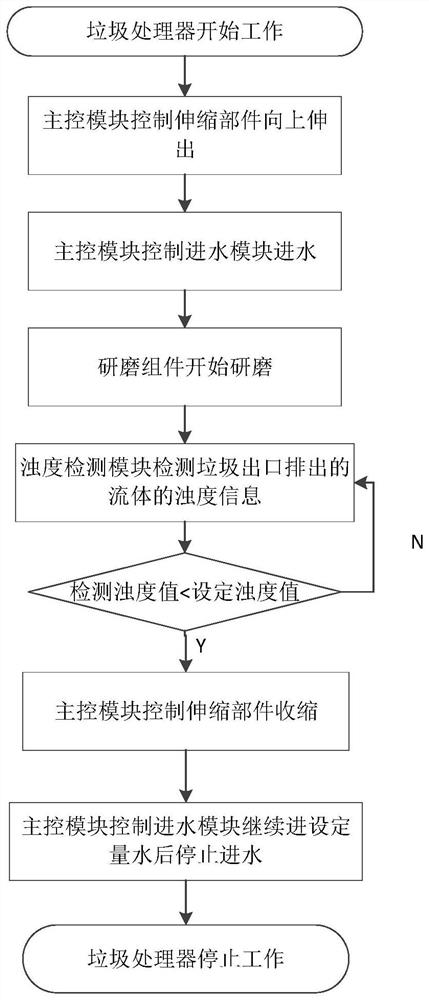

[0082] like Figure 1 to Figure 3 As shown, this embodiment also provides a control method for a garbage disposer, which is applied to the garbage disposer 1 of the first embodiment. The control method includes the following steps: when the garbage disposer 1 starts to work, the driving mechanism 13 The hose 121 is controlled to switch from the first U-shaped state to the second straight state.

[0083] The above-mentioned control method of the garbage disposer provided in this embodiment is mainly aimed at the problem that the garbage discharged after the garbage disposer 1 is processed is easily deposited at the bottom of the U-shaped sewer pipe 12 and causes blockage. The hose 121 is released so that the hose 121 is switched from the U-shaped to the straight-shaped, thereby effectively preventing the clogging caused by the accumulation of garbage at the bottom of the U-shaped tube.

[0084] Optionally, combine figure 2 and image 3 As shown, the control method further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com