Industrialized seedling raising system based on stacked tray darkroom technology

A darkroom and technology technology, applied in the field of darkroom seedling raising, can solve the problems of affecting seedling effect, large difference in growth rate, uneven seed germination, etc., and achieve the effect of reducing temperature and extending the distance of gas flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

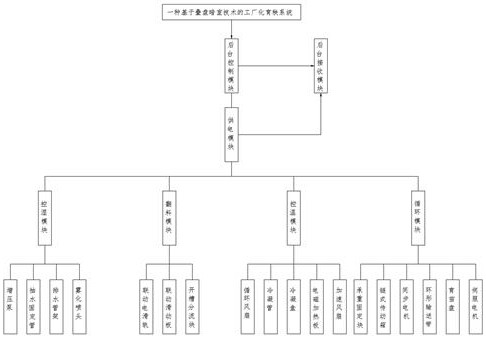

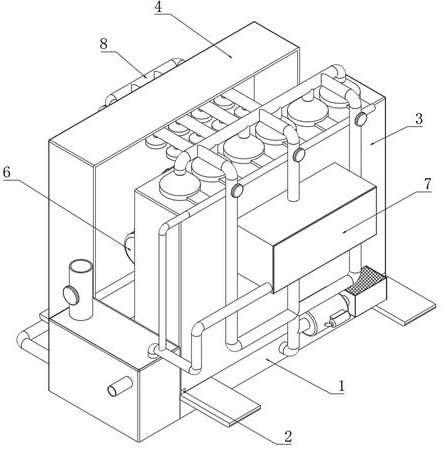

[0040] Example: as Figure 1-9 As shown in the figure, the present invention provides a technical solution, a factory-based seedling raising system based on the stacking darkroom technology, including a power supply module, a circulation module, a material turning module, a temperature control module, a humidity control module, a background receiving module and a background control module ;

[0041] The background control module is respectively connected with the power supply module, the circulation module, the material turning module, the temperature control module, the humidity control module and the background receiving module;

[0042] The power supply module is respectively connected with the circulation module, the material turning module, the temperature control module, the humidity control module and the background receiving module;

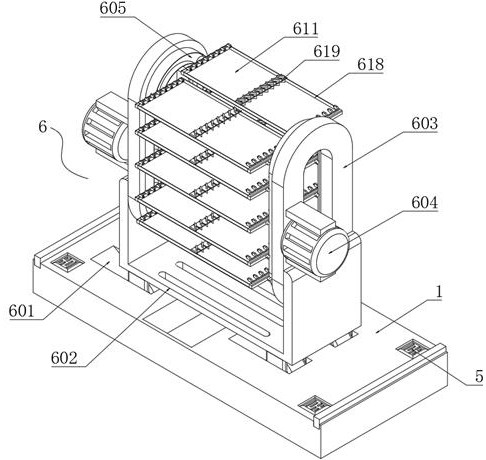

[0043] The circulation module includes a load-bearing fixed block 1, a chain transmission box 603, a synchronous motor 604, an endless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com