Cylindrical lens grating with staggered cylindrical lens units, 3D display screen and manufacturing method of cylindrical lens grating

A technology of lenticular grating and display screen, applied in optics, optical components, instruments, etc., can solve the problems of insufficiently balanced stereoscopic display screen resolution, large difference in resolution loss, etc., to improve display effect, prevent light interference, show good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved objects and effects of the present invention in detail, the following detailed description is given in conjunction with the embodiments and the accompanying drawings.

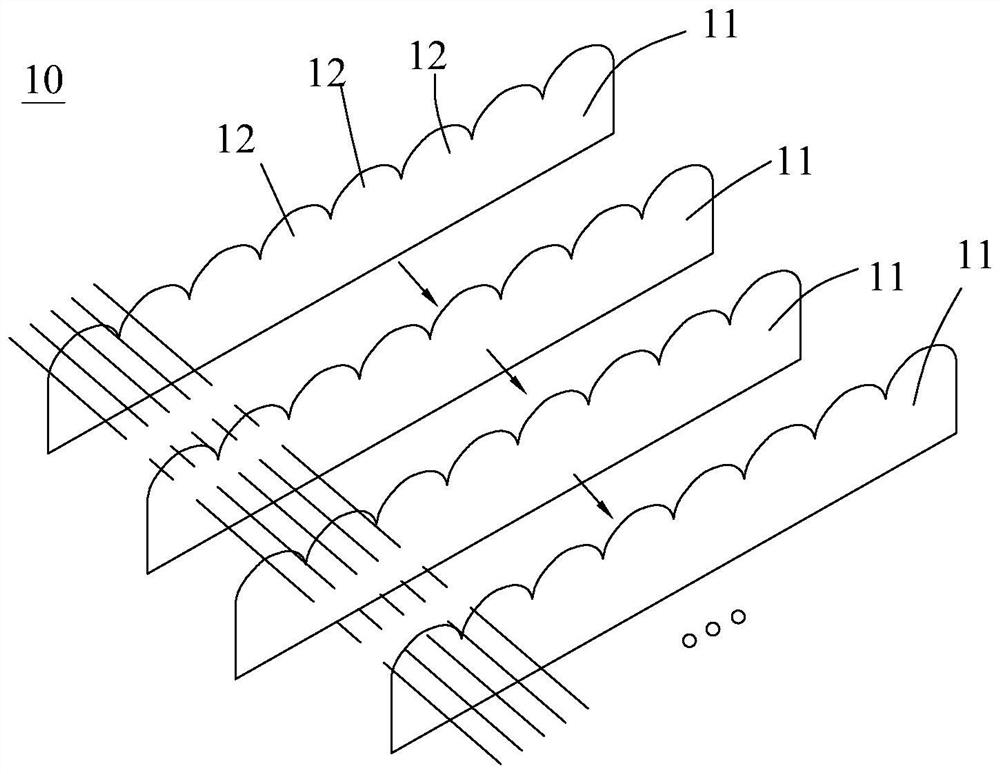

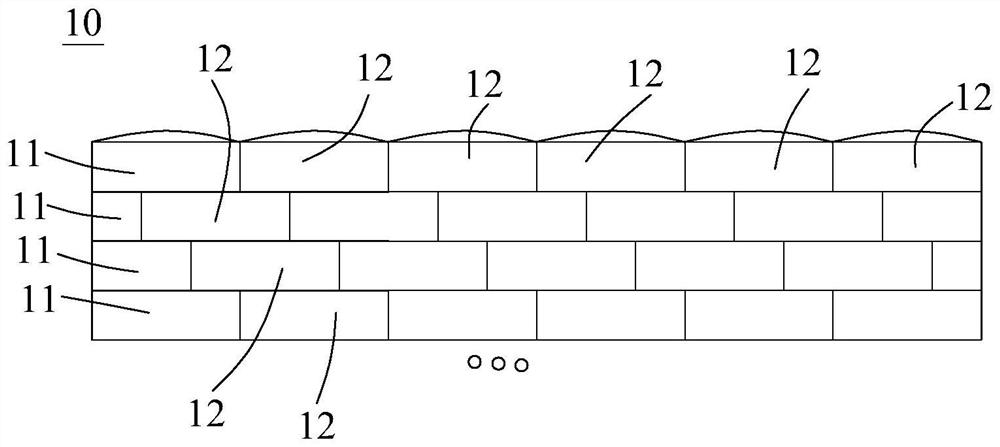

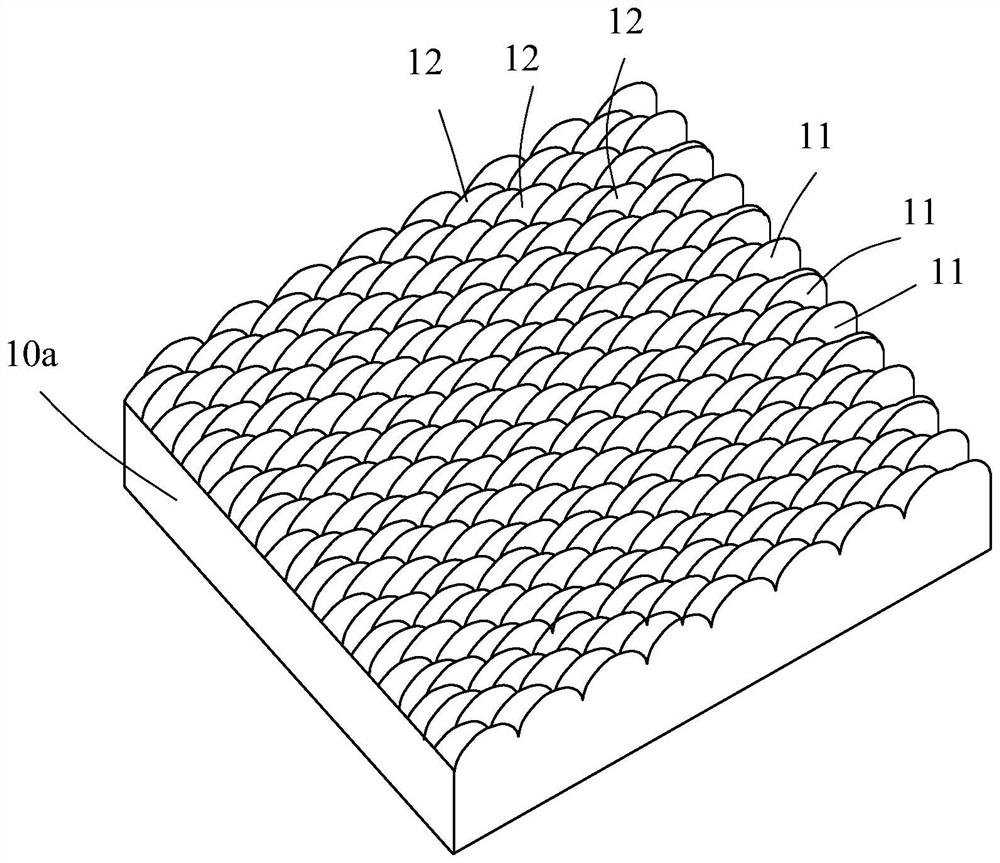

[0029] refer to Figure 1 to Figure 3 , the present invention discloses a lenticular grating 10 with interlaced lenticular units 12, comprising several lenticular grating sheets 11, each lenticular grating sheet 11 has several lenticular units 12 along the length direction, the lenticular unit 12 The width direction of the lenticular grating sheet 11 corresponds to the length direction of the lenticular grating sheet 11 , the length direction of the lenticular lens unit 12 corresponds to the thickness direction of the lenticular grating sheet 11 , and a plurality of the lenticular grating sheet 11 along the thickness direction The directions are stacked in sequence, and staggered along the length direction by a distance of N / M of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com