Method for evaluating fire risk classification management of chemicals in storage process

A technology for classified management and chemicals, applied in the direction of chemical analysis using combustion, rigid containers, analytical materials, etc., can solve the problems of lack of classification and inspection methods, unclear classification of chemical storage fire hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

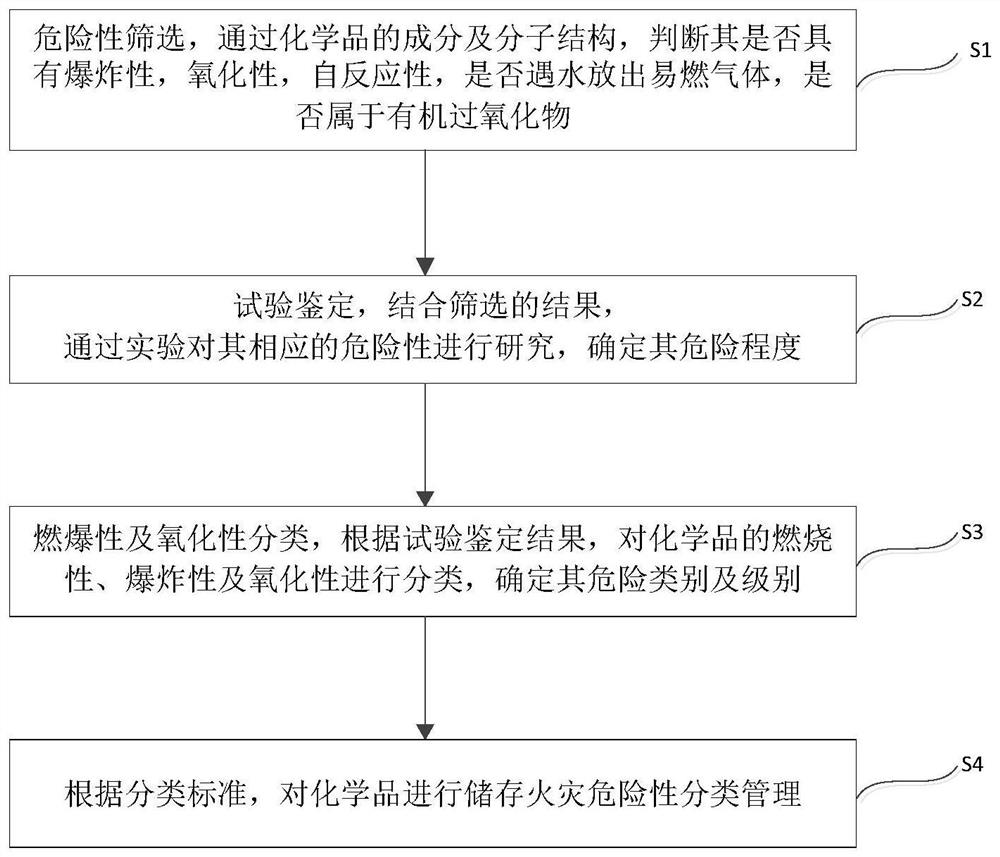

[0053] combine Figure 1 to Figure 7 As shown, a specific embodiment of a method for evaluating the classification and management of fire hazard during storage of chemicals provided by the present invention will be described.

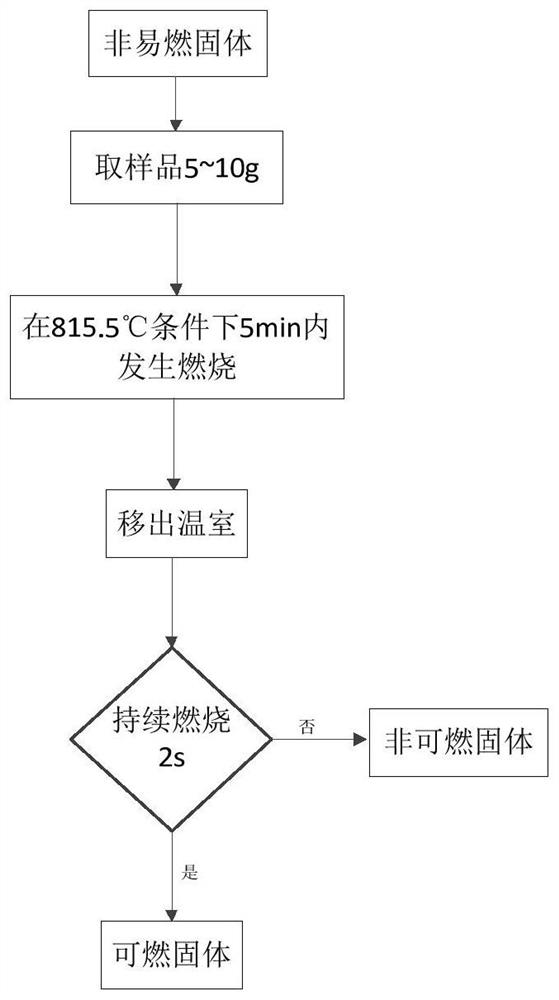

[0054] A method for evaluating the classification management of fire hazard in the storage process of chemicals, formulating the classification standard of storage fire hazard, and clearly classifying the storage fire hazard of five categories A, B, C, D, and E; Flammable, flame-retardant and non-combustible chemicals in fire hazard are defined and corresponding experimental test methods are formulated; according to storage fire hazard classification standards and experimental test methods, a fire hazard classification process is formulated.

[0055] The specific steps include:

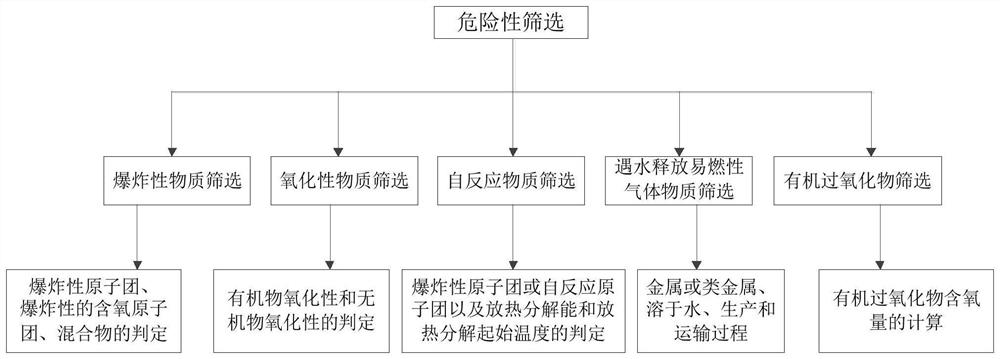

[0056] Step S1. Carry out hazard screening, determine the explosiveness, oxidativeness and self-reactivity of the chemical, determine the water-contacting property of the chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com