Filter screen assembly for air conditioner, air conditioner and working method of air conditioner

A filter and air conditioner technology, applied in air conditioning systems, applications, heating methods, etc., can solve problems such as poor filtering effect, noise, and the air outlet cannot be disassembled and cleaned.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

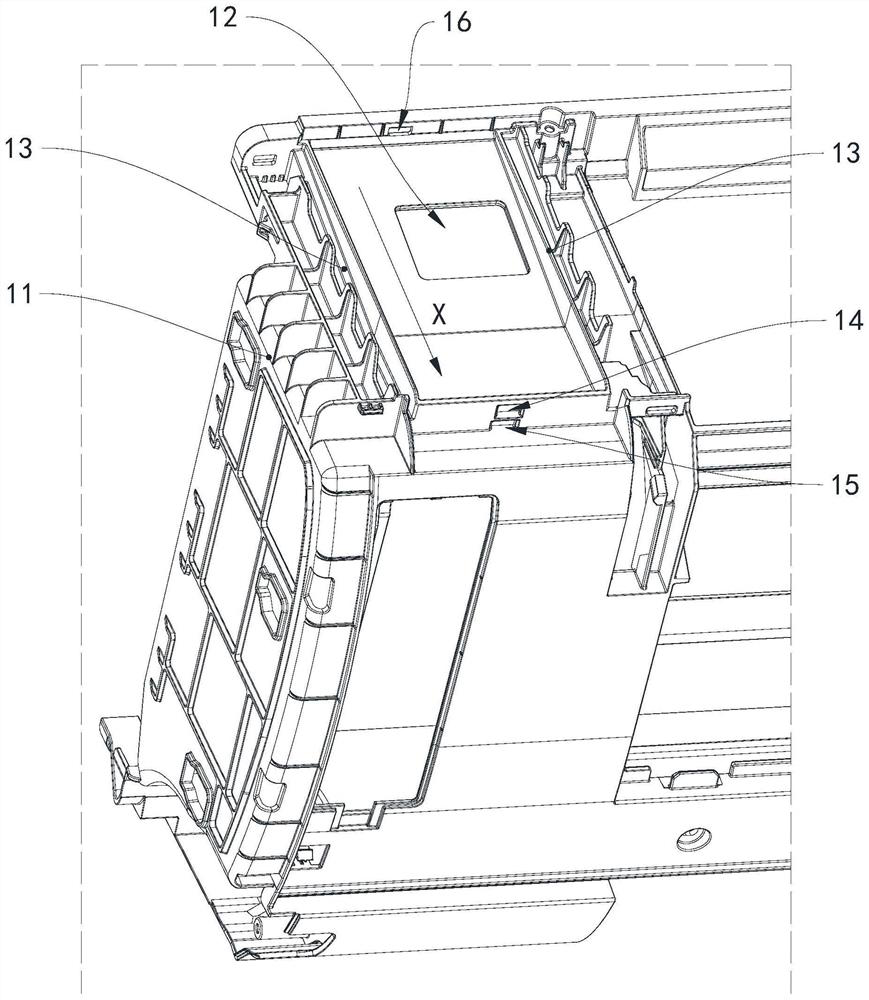

[0047] see figure 1 and figure 2The air conditioner includes an air conditioner housing 11 , a fresh air module and a filter screen assembly 2 . The air conditioner housing 11 is provided with a vent 12 , and the filter screen assembly 2 is detachably installed at the vent port 12 and covers the vent port 12 . The ventilation port 12 is located at one end of the air conditioning housing 11 in the length direction, the fresh air module is located in the air conditioning housing 11 and is close to the ventilation opening 12 , and the air processed by the fresh air module is discharged from the ventilation opening 12 .

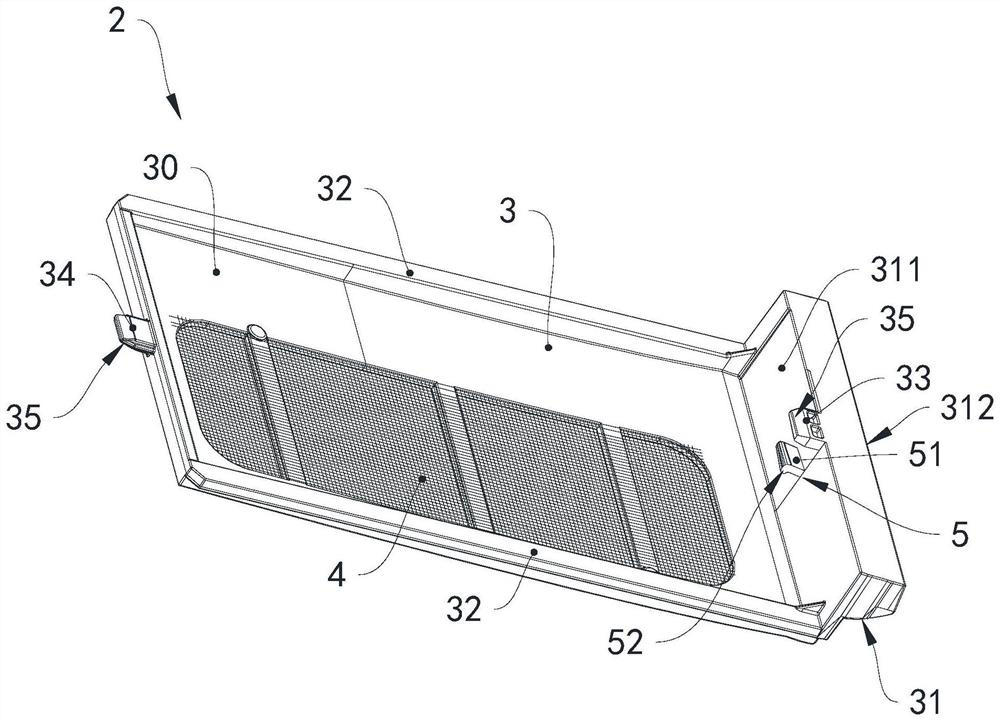

[0048] see Figure 2 to Figure 6 , the filter mesh assembly 2 includes a filter mesh support 3 and a filter mesh 4, the filter mesh 4 is mounted on the filter mesh support 3, the filter mesh support 3 includes a support body 30 and a pull handle 31, the support body 30 is provided with an opening 301, and the filter mesh 4 Cover the opening 301, the direction ...

no. 2 example

[0054] As a description of the second embodiment of the filter screen assembly of the present invention, only the differences from the first embodiment of the filter screen assembly described above will be described below.

[0055] see Figure 7 and Figure 8 The cross section of the pull handle 231 perpendicular to the width direction of the filter screen bracket is arc-shaped, and the buckle 25 is located on the pull handle 231 and extends in the opposite direction of the pull direction. A first plug portion 233 is provided on the side of the pull handle 231 away from the bracket body 230 , the first plug portion 233 extends parallel to the pulling direction, and one end of the bracket body 230 away from the pull handle 231 is provided with a second plug portion 234, the second plug portion 234 extends parallel to the drawing direction.

[0056] A limiting protrusion 2321 is provided on the slide rail 232 . The limiting protrusions 2321 can make the sliding rails 232 inte...

no. 3 example

[0060] As a description of the third embodiment of the filter screen assembly of the present invention, only the differences from the first embodiment of the filter screen assembly described above will be described below.

[0061] see Figure 9 In this embodiment, the matching guide rail 313 is formed by the air inlet baffle bracket 3101 and the limiting ribs 3102 of the panel body. A chute 3131 for matching the guide rail 313 is formed between the limiting ribs 3102 of the body, and the filter screen assembly 320 is slidingly matched with the chute 3131 . Along the pulling direction, the width of the end of the chute 3131 away from the pull handle 331 is smaller than the width of the end of the chute 3131 close to the pull handle 331 . The width of the chute 3131 at one end away from the pull handle 331 is small, which can ensure proper assembly and prevent the filter screen assembly 320 from shaking. disassembly and assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com