Sectional cementing grouting filling method for coal mine caving area

A cementation and coal mine technology, applied in the fields of filling, mining equipment, earthwork drilling, etc., can solve the problems of air leakage in the goaf, and achieve the effects of low cost, easy operation, and broad application and promotion prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

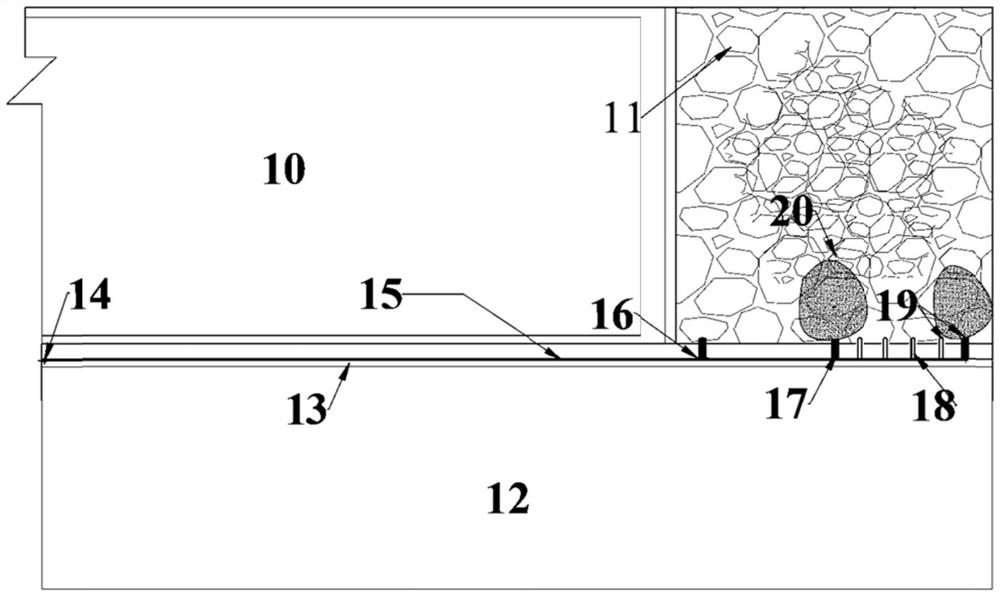

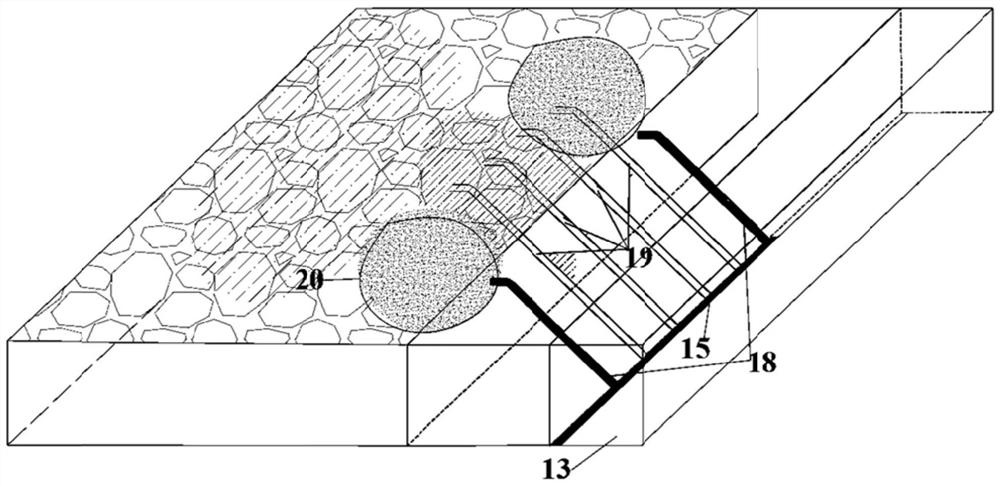

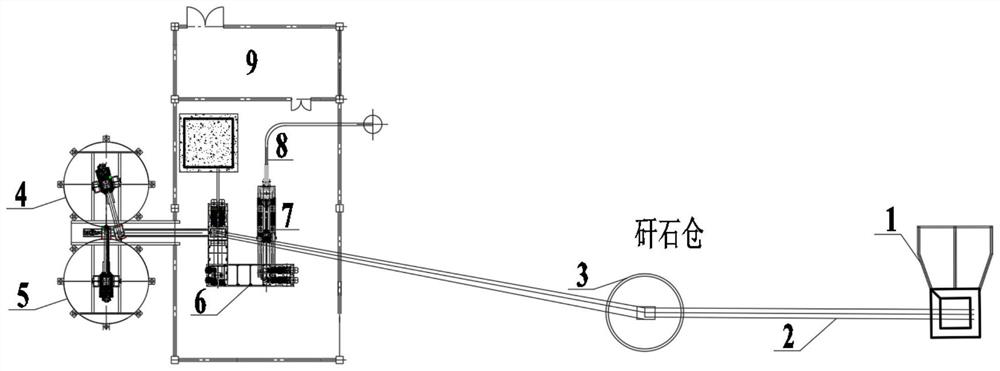

[0043] From the mining roadway 13 of the adjacent continuous working face 12, a number of filling holes are constructed through the coal pillar to this working face.

[0044] Cement grouting fills the hole with pre-buried steel pipes 19, and the spacing is reasonably selected according to the actual conditions of the mining roadway 13 and the advancing speed of the working face, and the construction position of the orifice is in the mining roadway 13;

[0045] The raw gangue grouting filling hole 18 is sleeved on the side of the mining roadway 13 adjacent to the continuous working face 12, and the filling pipeline is connected. The spacing is reasonably arranged according to the diffusion radius of the high-parameter raw gangue fluidized slurry. Drop off top.

[0046] When the working face is advanced to the position of the cemented grouting filling hole 17, the flexible membrane bag 20 is connected to the orifice on one side of the working face; through inspection and contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com