Fabricated prefabricated enclosing wall

A prefabricated and fenced technology, which is applied in fences, building types, buildings, etc., can solve problems such as pollution, time-consuming and material quality of fences, and poor environment, so as to achieve good durability, speed up project construction, and ensure construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

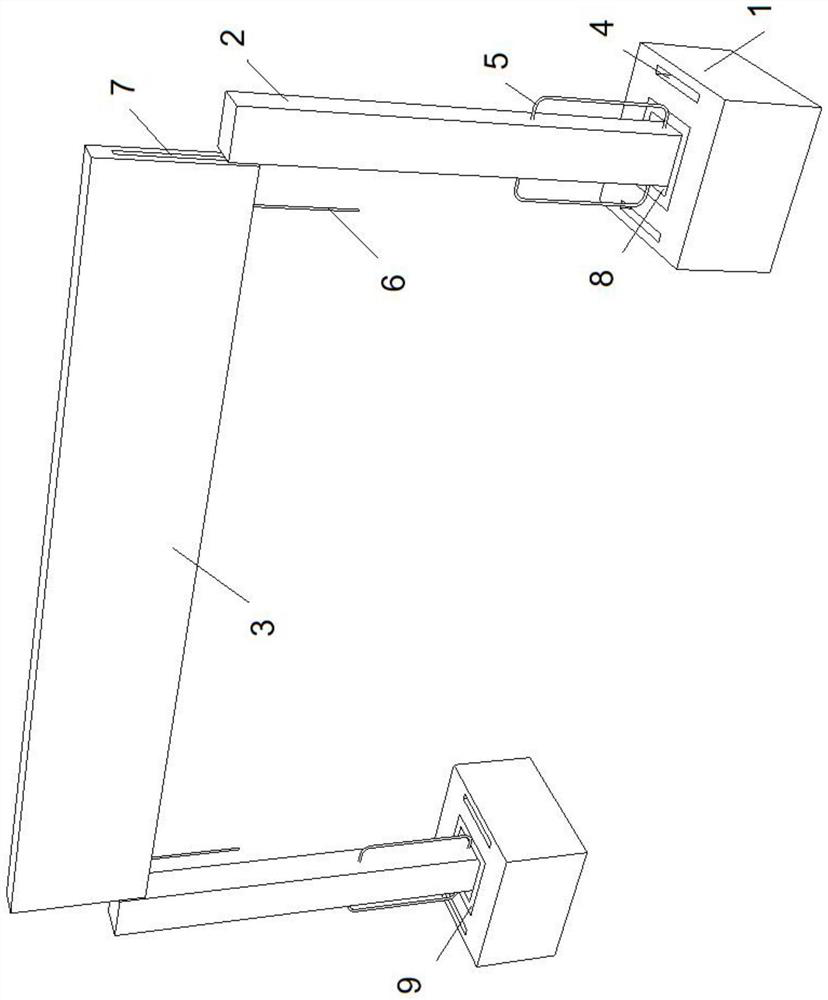

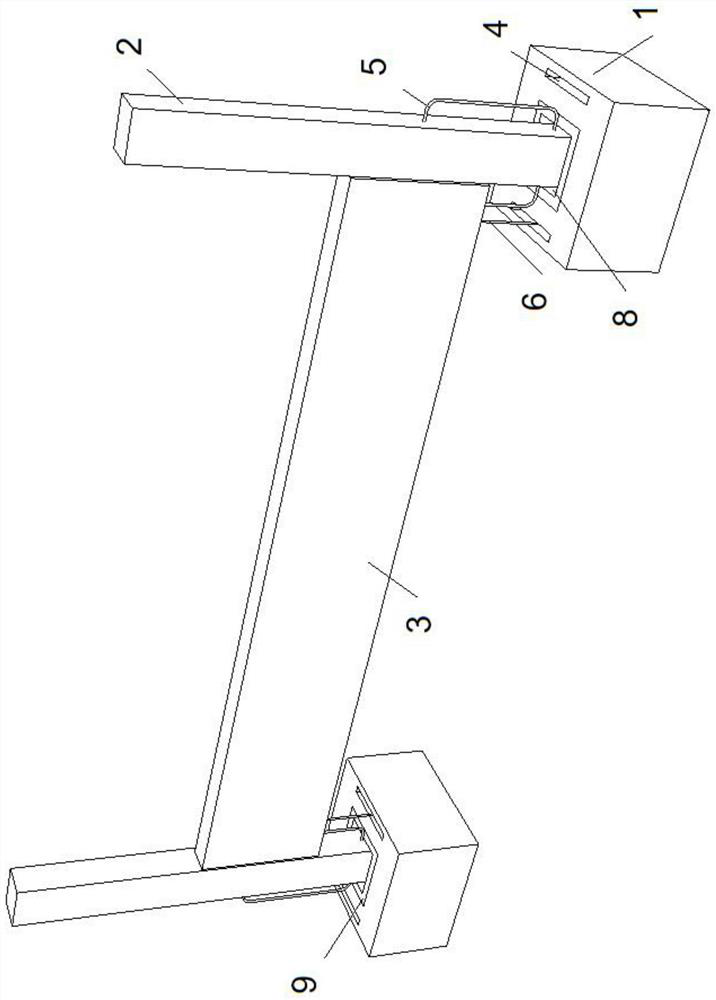

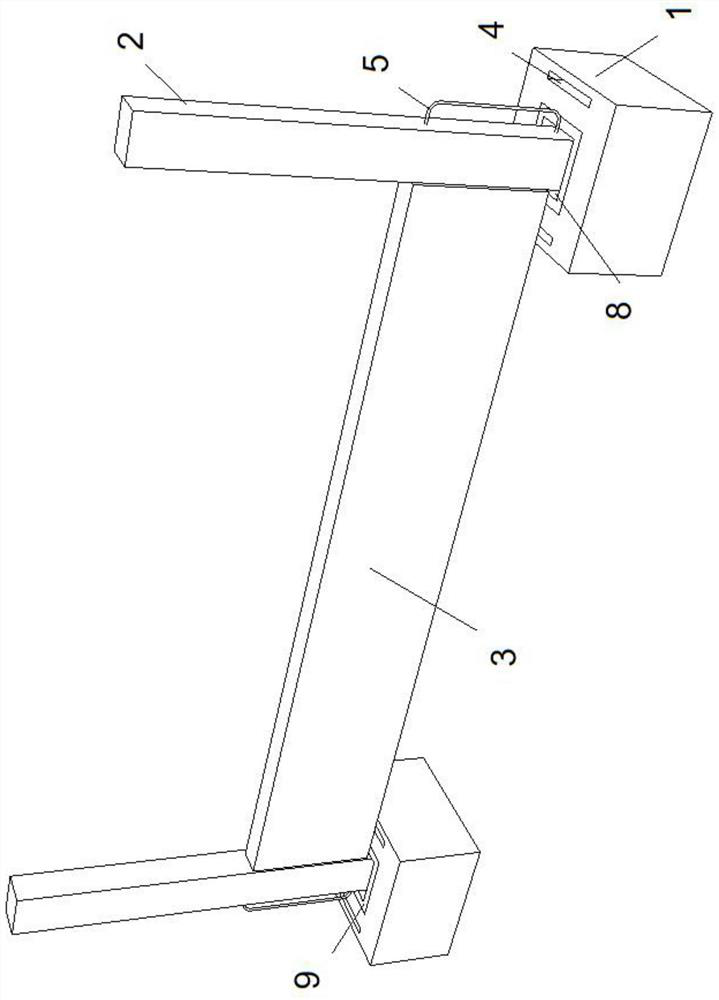

[0018] A prefabricated prefabricated wall proposed by the present invention includes a prefabricated foundation 1, a prefabricated column 2 and a prefabricated low wall 3;

[0019] like Figure 1-2 As shown, the upper end face of the prefabricated foundation 1 is provided with a prefabricated foundation cup-shaped slot 8 vertically, the left and right sides of the prefabricated foundation cup-shaped slot 8 are vertically arranged with a foundation limit slot 4, and the prefabricated foundation 1 is provided with two groups; the prefabricated column 2 Two groups are vertically arranged, the bottoms of the two groups of prefabricated columns 2 are inserted into the two groups of prefabricated foundation cup-shaped slots 8 respectively, and the left and right sides of the bottom of the prefabricated columns 2 are provided with prefabricated column limit bars 5, and the prefabricated column limit bars 5 are located at Above the prefabricated foundation 1 and in contact with the to...

Embodiment 2

[0024] like figure 1 As shown in the figure, in the prefabricated prefabricated enclosure proposed by the present invention, compared with the first embodiment, prefabricated foundation metal embedded parts 9 are arranged on the inner wall of the prefabricated foundation cup-shaped slot 8, and the outer wall of the bottom of the prefabricated column 2 is embedded with the prefabricated foundation metal. The inner wall of piece 9 is fitted. The prefabricated base metal embedded parts 9 have high strength and can ensure the verticality of the prefabricated columns 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com