Silk thread circular blowing cooling device for textile production

A cooling device and textile technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of weak air flow, spinning dirt and deformation, slow spinning cooling and forming process, etc., to achieve cooling The effect of small molding and low degree of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

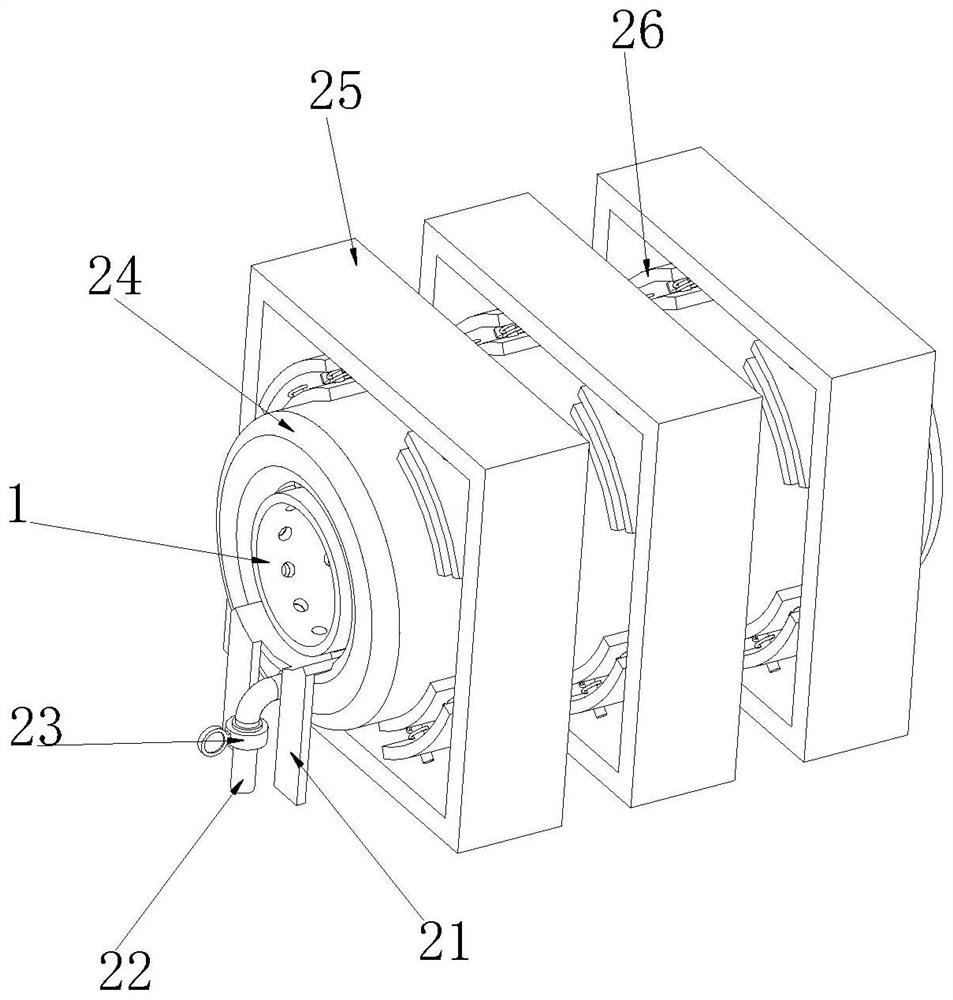

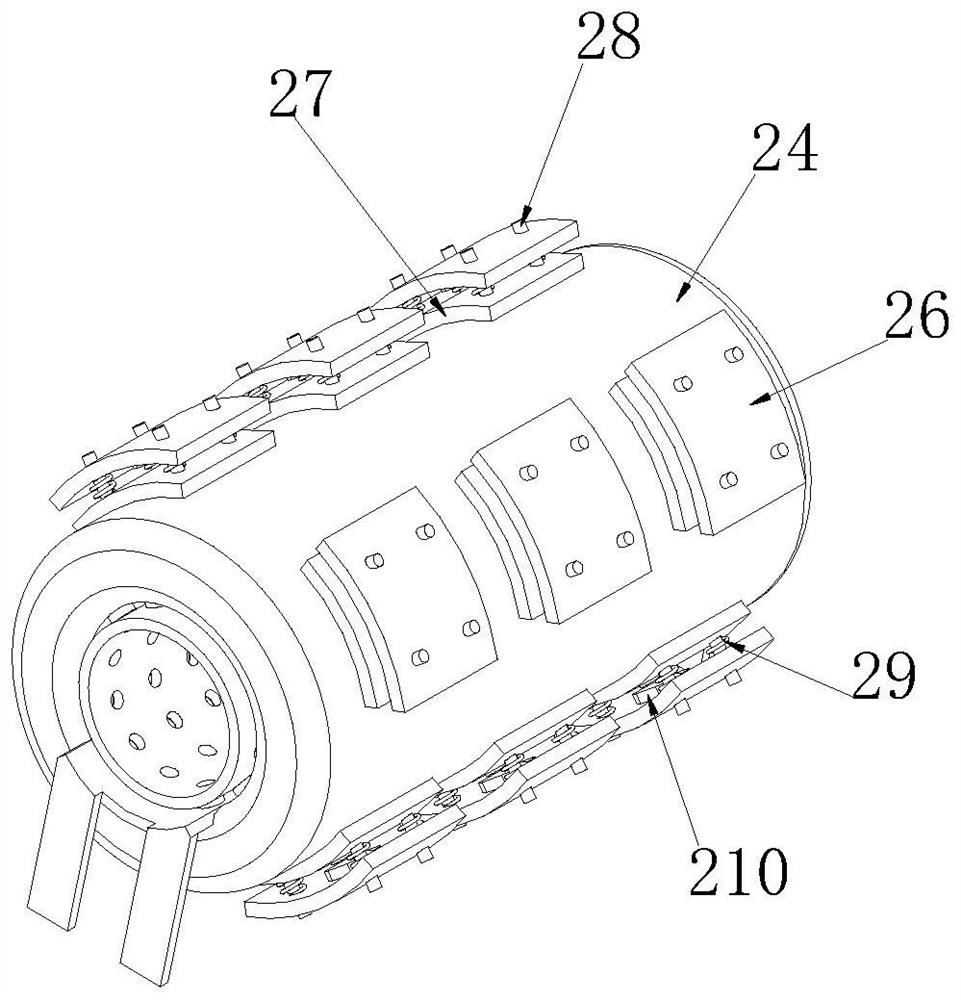

[0029] see Figure 1-2 As shown, a wire ring blowing cooling device for textile production includes a ring blowing sleeve 1, the outer side wall of the ring blowing sleeve 1 is provided with a ring blowing bracket 21, the upper end of the ring blowing bracket 21 is a cylindrical structure, and the lower end is a cylindrical structure. It is a four-leg structure, and the inner diameter of the cylindrical upper end structure is larger than the outer diameter of the ring blowing sleeve 1. The outer side wall of the ring blowing bracket 21 is connected with a rubber air bag 24, and one side of the outer side wall of the ring blowing bracket 21 is connected to the air inlet. Pipe 22, the outer side wall of the air inlet pipe 22 is connected with a first control valve 23, the inner side wall of the ring blowing bracket 21 is connected with a communication pipe at the position of the hole on the outer side wall of the ring blowing sleeve 1, and the outer side wall of the communication...

Embodiment 2

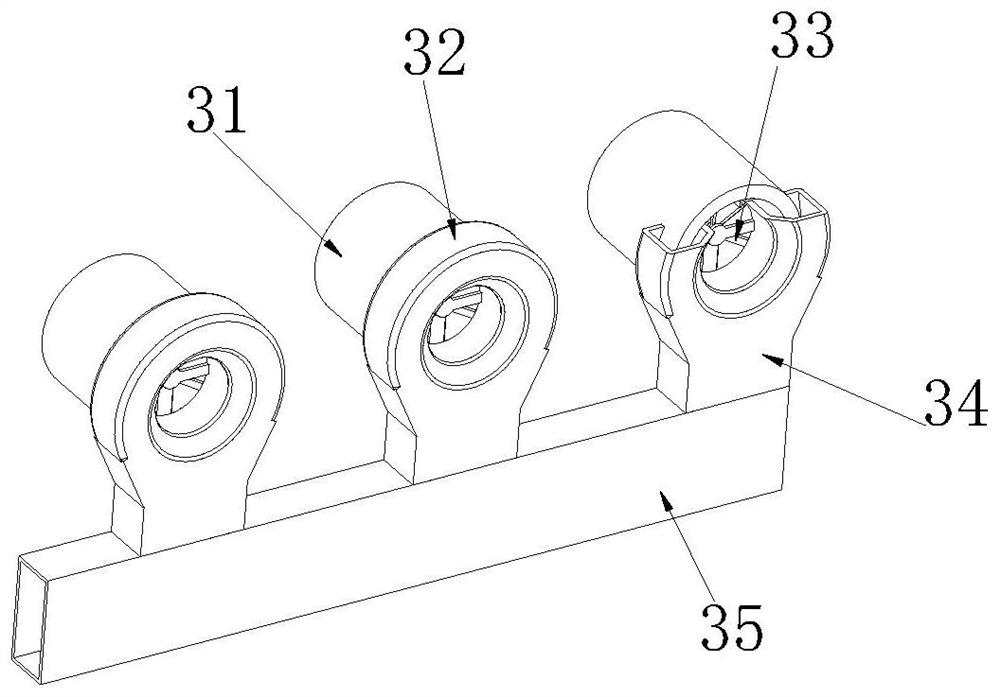

[0033] see Figure 3-4 As shown, the inner side wall of the ring blowing sleeve 1 is connected with an air duct 31 at the position corresponding to the hole, and the end of the air duct 31 away from the ring blowing sleeve 1 is connected with a miscellaneous exhaust sleeve 32, and the outer diameter of the miscellaneous sleeve 32 is larger than that of the air guide. The size of the outer diameter of the pipe 31, the size of the inner diameter is equal to the size of the inner diameter of the air duct 31, the inner wall of the miscellaneous exhaust sleeve 32 is in close contact with the inner wall of the air duct 31, and one side of the outer side wall of the miscellaneous exhaust sleeve 32 is integrally formed. Inside the miscellaneous sleeve 32, one end close to the air duct 31 is connected with a miscellaneous discharge rotating blade 33, the bottom end of the miscellaneous pipe 34 is connected with a miscellaneous discharge pipe 35, and the outer side wall of the miscellane...

Embodiment 3

[0037] see Figure 5-8 As shown, the rubber airbag 24 is provided with a rotating groove 44, the number of rotating grooves 44 is two, and the two rotating grooves 44 are respectively connected on both sides of the ring blowing bracket 21, and the inner side wall of the rotating groove 44 is slidably connected with a rotating frame 43 A connecting plate 45 is connected to the side of the outer side wall of the rotating frame 43 away from the ring blowing bracket 21 , a cleaning sponge is connected to the side of the outer side wall of the connecting plate 45 that is close to the rubber airbag 24 , and the side of the outer side wall of the rotating frame 43 that is close to the air inlet duct 22 An interlocking groove 42 is integrally formed, the inner side wall of the ring blowing bracket 21 is connected with a rotating bracket 46 at the position corresponding to the interlocking groove 42, and the middle position of the outer side wall of the rotating bracket 46 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com