Self-elevating ocean platform pile leg and pile shoe equipment cable take-up and pay-off system

An offshore platform and self-elevating technology, applied in the field of ship design and construction, can solve the problems of small scope of application, high labor intensity, and few types of cables, so as to enhance safety and convenience, improve automation, and ensure electrical continuity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

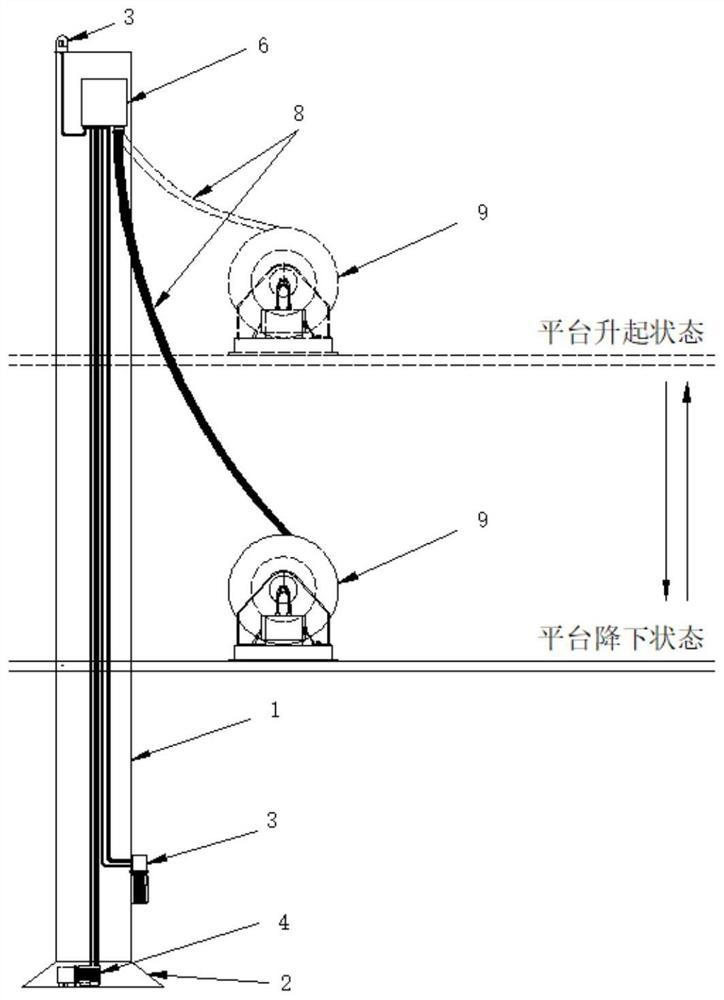

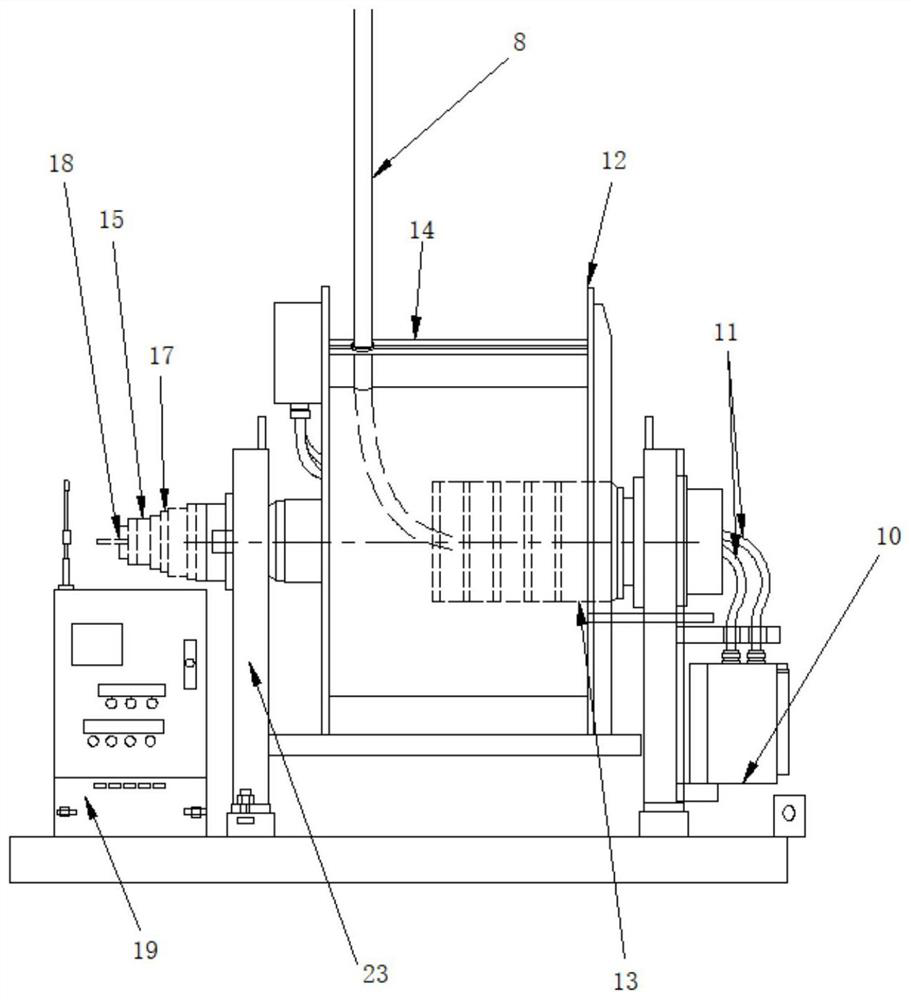

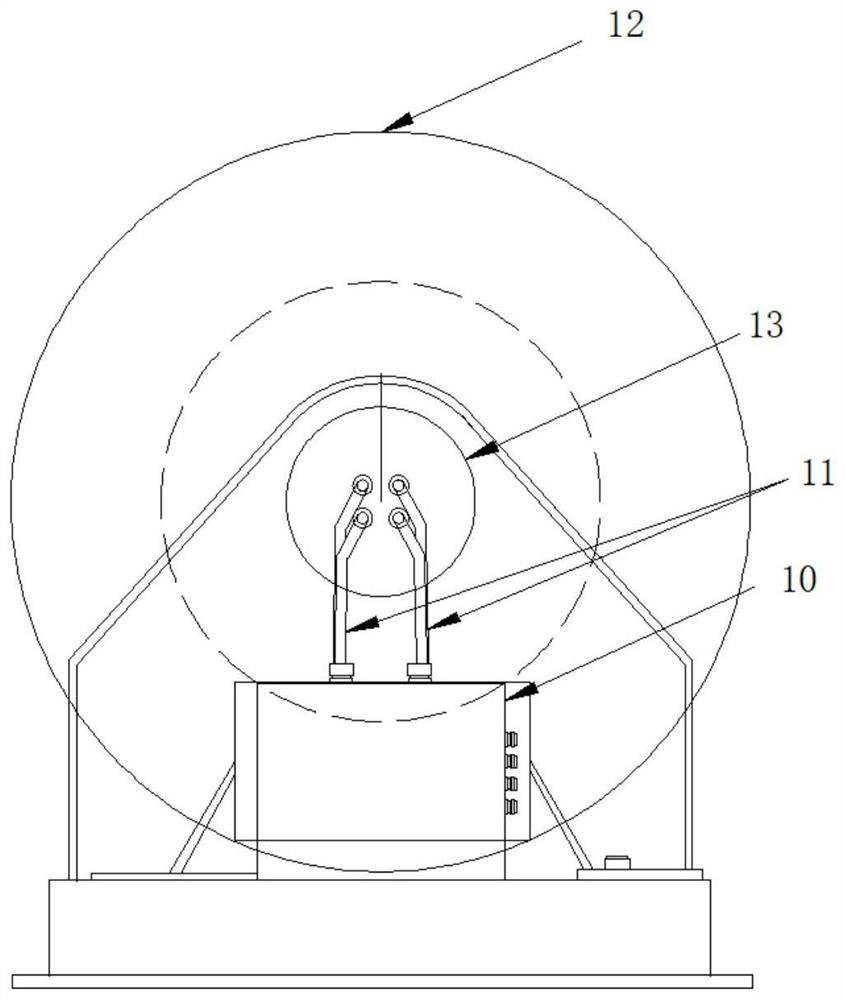

[0026] The present invention will be further described with reference to the accompanying drawings.

[0027] like figure 1 Shown is a self-elevating offshore platform pile leg and pile shoe equipment cable retraction system, which has pile legs placed upright, and pile shoes at the bottom of the pile legs. The pile legs are provided with a plurality of pile leg equipment. There are also a plurality of spud shoe devices, and these spud leg devices and spud shoe devices are connected with a variety of different types of cables to transmit power and execution signals. The types of these cables include power cables and control cables. A junction box is arranged on the top of the leg, and the cables connected to the leg equipment and the pile boot are collected into the junction box to form a flexible composite cable. Eventually a flexible composite cable (such as Figure 4 shown). Flexible composite cables or even electric winches, wound around the shafts that the electric winc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com