Continuous liquid-liquid homogeneous reactor

A homogeneous reactor and reaction technology, applied in chemical methods, chemical/physical/physical chemistry stationary reactors, chemical instruments and methods for making liquids react with liquids, etc., which can solve the problems of long residence time and large volume. , to achieve the effects of easy concentration control, high reaction conversion rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and embodiments.

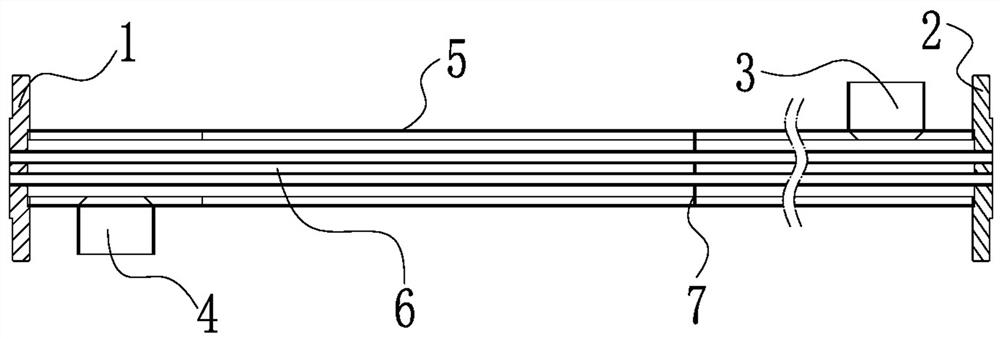

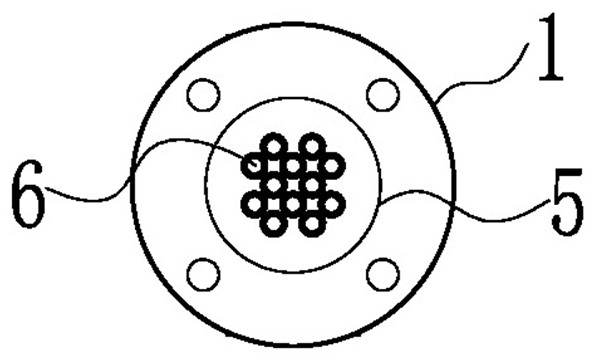

[0021] refer to figure 1 and figure 2 , at least one reaction tube 6 is placed in the casing 55 of the present invention, and the two ends of the casing 55 are fixed with a flange (liquid inlet) 1 and a flange (liquid outlet) 2, The two ends of the reaction tube 6 are respectively fixedly connected with the flange (liquid inlet) 1 and the flange (liquid outlet) 2, and the tube wall near the two ends of the sleeve 55 is also provided with a cooling and heating medium outlet. 3. Inlet and outlet, the sleeve 55 with the reaction tube 6 is also fixed with a reaction tube support 7.

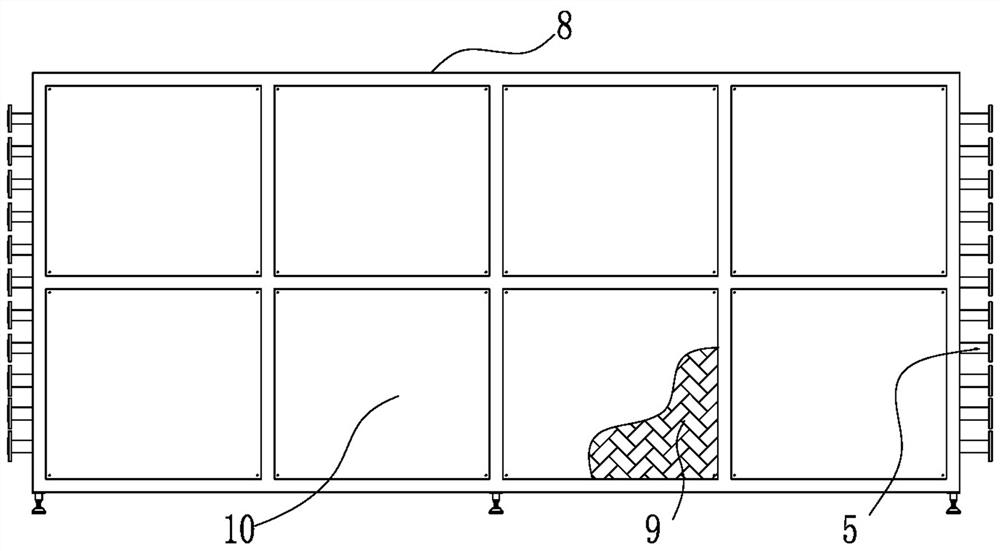

[0022] refer to image 3 and Figure 4 , when a plurality of sleeves 55 of the present invention are used in combination, at least one sleeve 55 with a reaction tube 6 is fixedly arranged in the box 8, and the box 8 is also provided with a thermal insulation filler 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com