Multifunctional transformer framework

A transformer skeleton and multi-functional technology, applied in the field of transformers, can solve problems such as inconvenience of use, hidden dangers of transformer safety, short circuit of coils, etc., and achieve the effects of accelerating heat dissipation, reducing danger, and avoiding coil contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

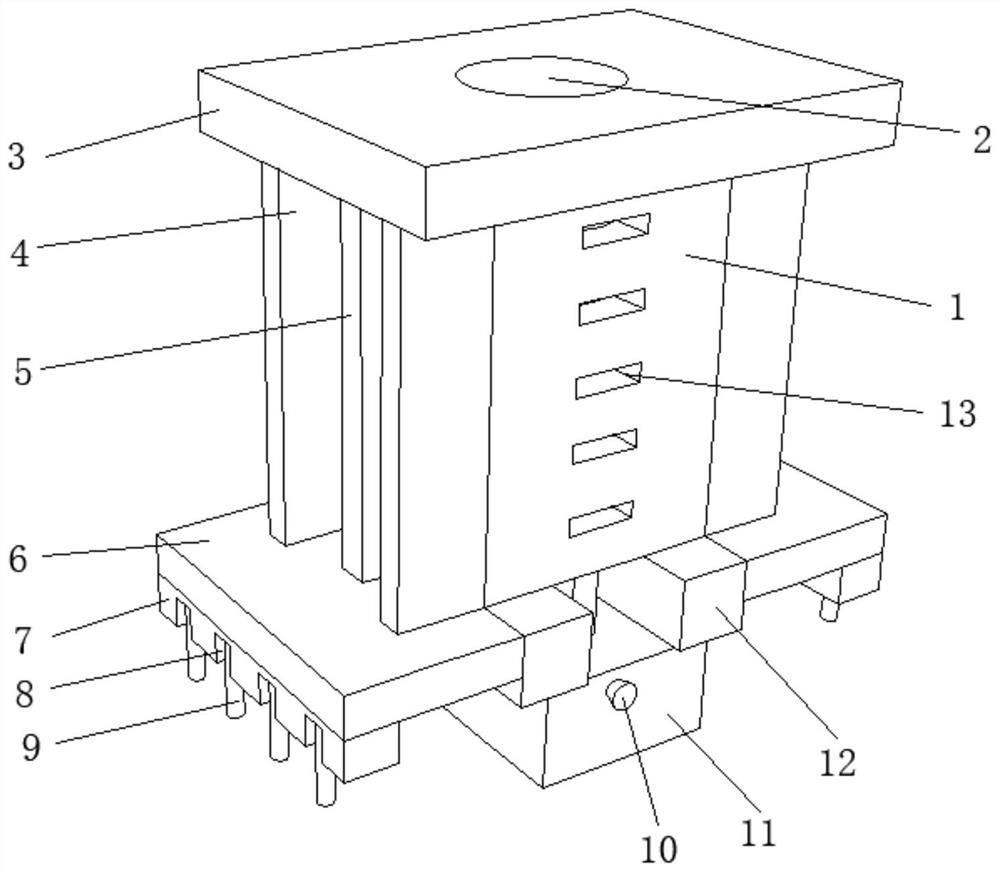

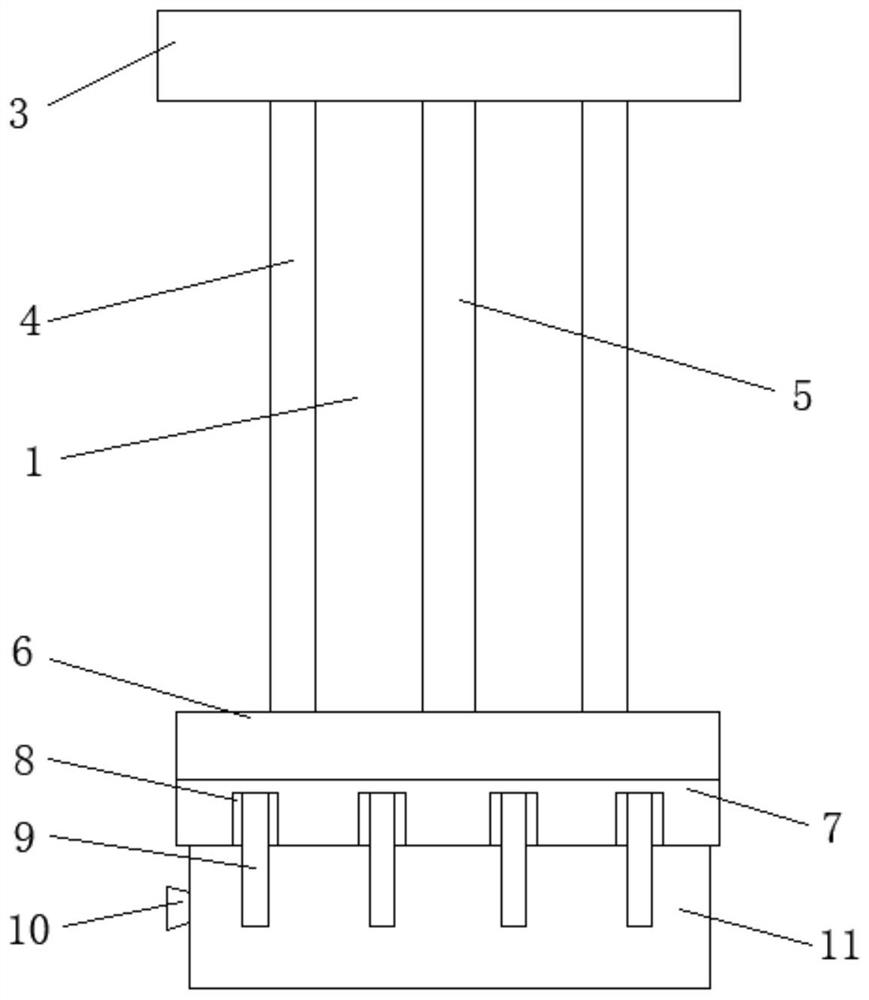

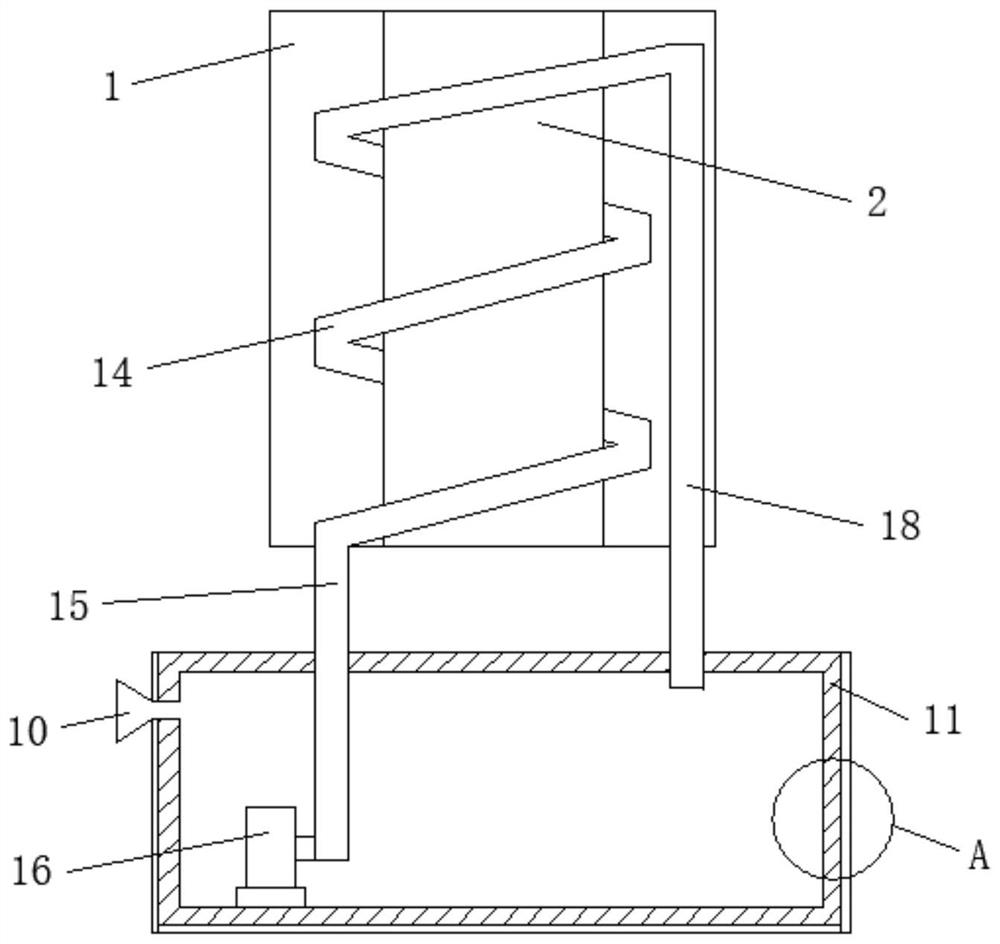

[0036] refer to Figure 1-4 , the present invention provides a multi-functional transformer skeleton, including a central column 1, the middle of the central column 1 is provided with a port 2, the left and right sides of the bottom end of the central column 1 are fixedly connected to the top of the beam frame 12, and the bottom of the beam frame 12 is fixedly connected. The ends are fixedly connected to the top of the water tank 11 , the inner wall of the bottom end of the water tank 11 is fixedly connected with a water pump 16 , the output end of the water pump 16 is fixedly connected to one end of the water inlet pipe 15 , and the other end of the water inlet pipe 15 is fixedly connected to one end of the annular pipe 14 . , the other end of the annular pipe 14 is fixedly connected to the top of the water outlet pipe 18, and the outer wall of the water tank 11 is provided with thermally conductive silica gel 17.

[0037] When the transformer is working, the coil is energize...

Embodiment 2

[0040] refer to Figure 1-4 , in the multifunctional transformer skeleton provided by the present invention, the top of the central column 1 is fixedly connected with a top plate 3, which plays a role of shielding, the through port 2 runs through the middle of the top plate 3, and the top middle of the bottom plate 6 is fixedly connected to the winding column 5. The bottom end, the top of the winding column 5 is fixedly connected with the top plate 3, the top of the baffle 4 is fixedly connected to the bottom end of the top plate 3, the baffle 4 surrounds the winding column 5 on the inside, the left and right sides of the center column 1 Baffles 4 are fixedly connected to the front and rear of the winding column 5, and baffles 4 are provided at the front and rear ends of the winding column 5 to isolate the coil wound on the surface of the winding column 5 in the interior, so as to achieve the purpose of isolating the coil and avoid the contact of the coil. Phenomenon.

Embodiment 3

[0042] refer to Figure 1-4 In the multifunctional transformer skeleton provided by the present invention, the top of the groove 8 is fixedly connected with a metal needle 9, the length of the metal needle 9 is greater than the length of the needle seat 7, and the metal needle 9 is arranged in the groove 8 to avoid contact with the coil. Contact, the annular pipe 14 is arranged inside the central column 1, the annular pipe 14 surrounds the outer circumference of the port 2, and the efficiency of heat dissipation is increased. Cooling liquid is added in the water tank 11 , and the front end of the center column 1 is evenly distributed with heat dissipation holes 13 , and the heat dissipation holes 13 all penetrate the center column 1 to achieve the effect of heat dissipation by air flow.

[0043]Working principle: When the transformer is working, the coil is energized to dissipate heat, and the water pump 16 transports the cooling liquid to the water inlet pipe 15, from the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com