Leachate pool capping structure

A technology of leachate and floating cover membrane, applied in infrastructure engineering, waterway systems, buildings, etc., can solve problems such as damage to anti-seepage systems, and achieve the effects of less input resources, convenient movement, and low renovation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

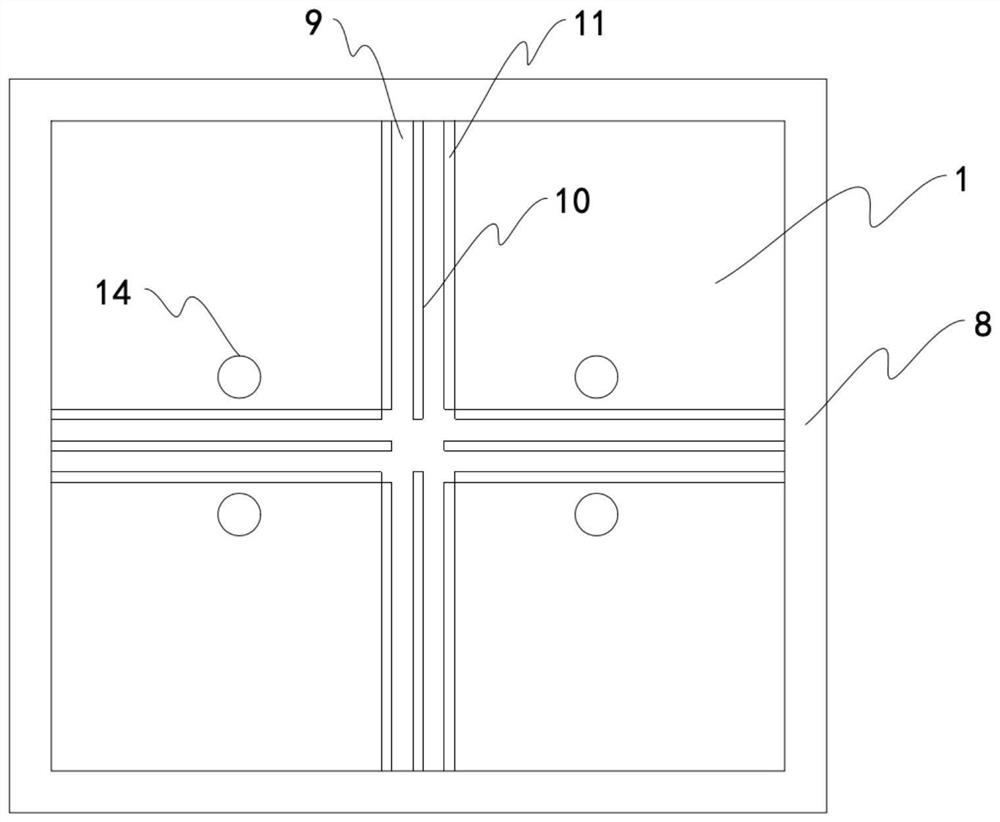

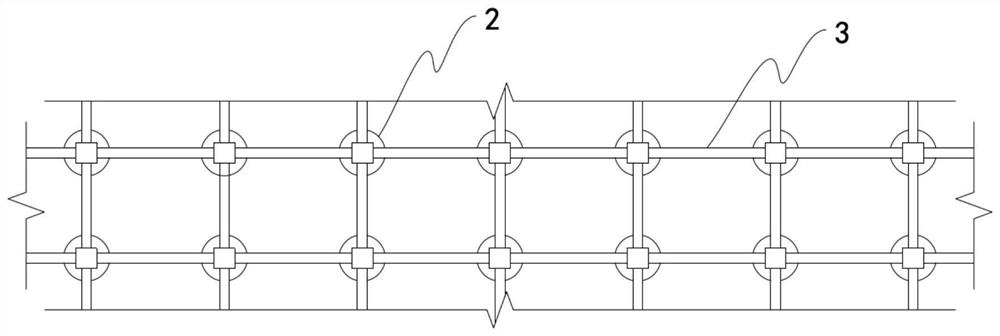

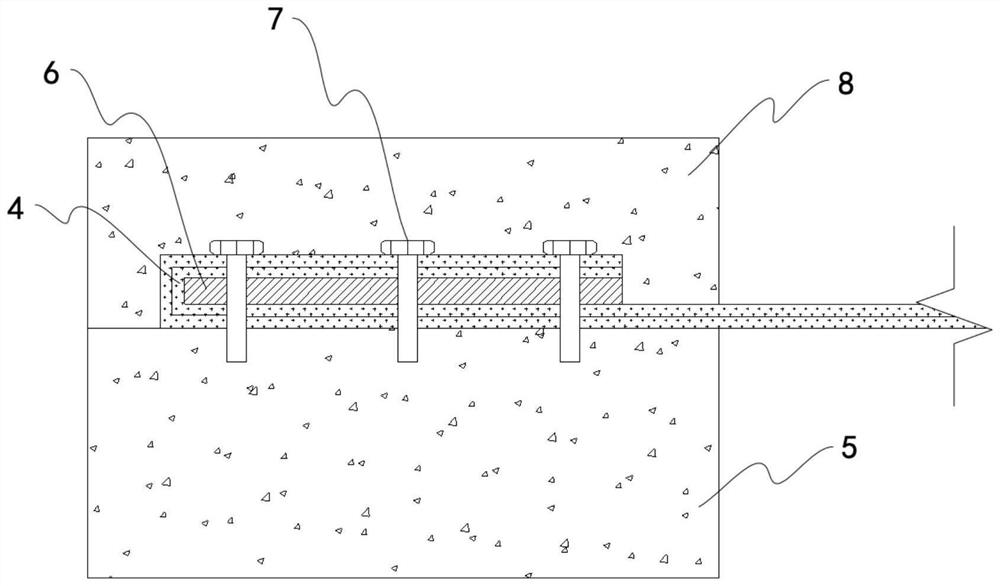

[0020] like Figure 1-4 As shown, a leachate tank capping structure includes a floating cover membrane main body 1, and also includes a concrete anchoring foundation 5 casted around the edge of the leachate tank. It is welded, the bottom of the floating cover film main body 1 is evenly connected with a plurality of floating ball strings, and the floating ball string is formed by a plurality of evenly distributed floating balls 2 connected in series by the HDPE film tape 3 and the anti-corrosion rope , the edge of the floating cover membrane main body 1 has an anchoring portion 4 exposed to the leachate pool, the anchoring portion 4 is laid flat on the concrete anchoring foundation 5, and the The end of the part 4 away from the leachate pool is rolled back and laid on the stainless steel plate 6, and the stainless steel plate 6 and the anchoring parts 4 located on the upper and lower sides of the stainless steel plate 6 are penetrated and fixed by the stainless steel expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com