Expanded-base prestressed composite anchor cable uplift pile, preparation method and equipment

A technology of prestressed and uplift piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, and can solve the problems of discounting the bearing capacity of piles, affecting the quality of uplift piles, and being unable to further improve the anti-floating capacity of uplift piles, etc. , to achieve the effect of guaranteeing the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

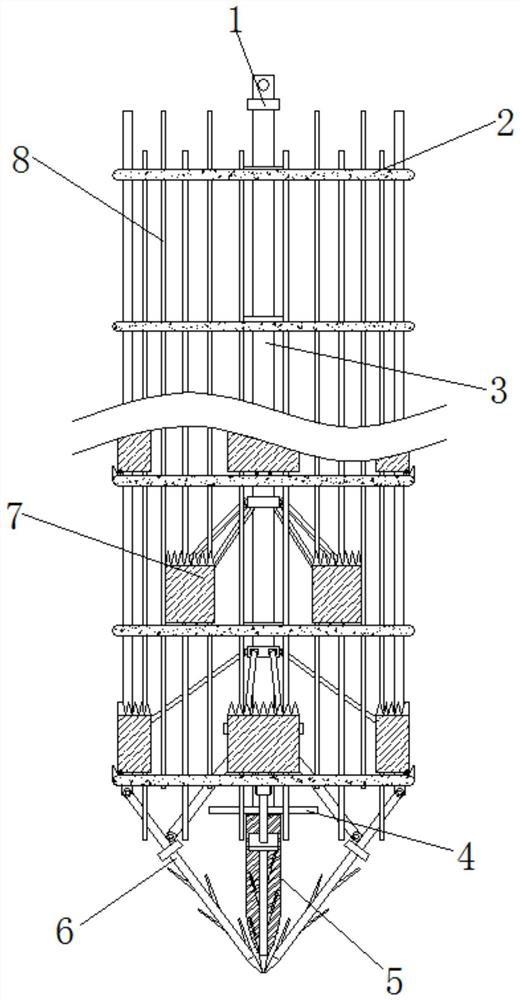

[0049] Further, the preparation method of the bottom-expanded prestressed composite anchor cable uplift pile, the method steps are as follows:

[0050] 1. First, place the uplift pile reinforcement cage composed of circular steel bars 2, straight steel bars and prestressed steel strands 8 into the pre-drilled holes on the ground through a crane;

[0051] 2. Then move the anti-pull pile preparation equipment to the outside of the hole, so that the outlet of the hole is located under the middle of the preparation equipment, then insert the I-beam 22 under the top group of circular steel bars 2, and put the I-beam The two ends of 22 are placed on the top of the U-shaped movable plate 17, so as to suspend the uplift pile reinforcement cage in the hole;

[0052] 3. Then, the output shaft of the gearbox 21 is fixedly connected with the connector 1 at the top of the main rod 3, and the second hydraulic cylinder 24 is controlled to rise, so that the bottom end of the insertion rod 6 i...

Embodiment 1

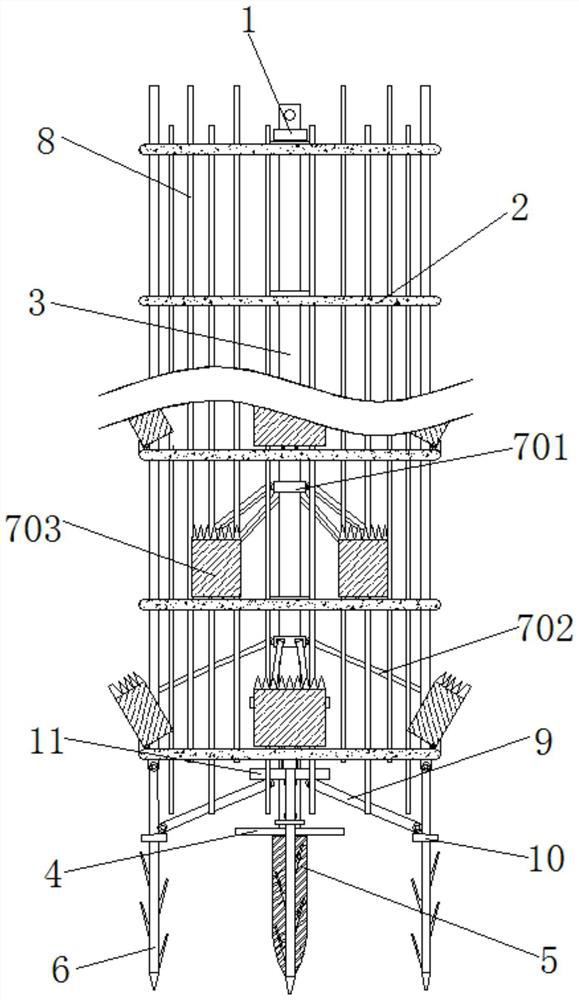

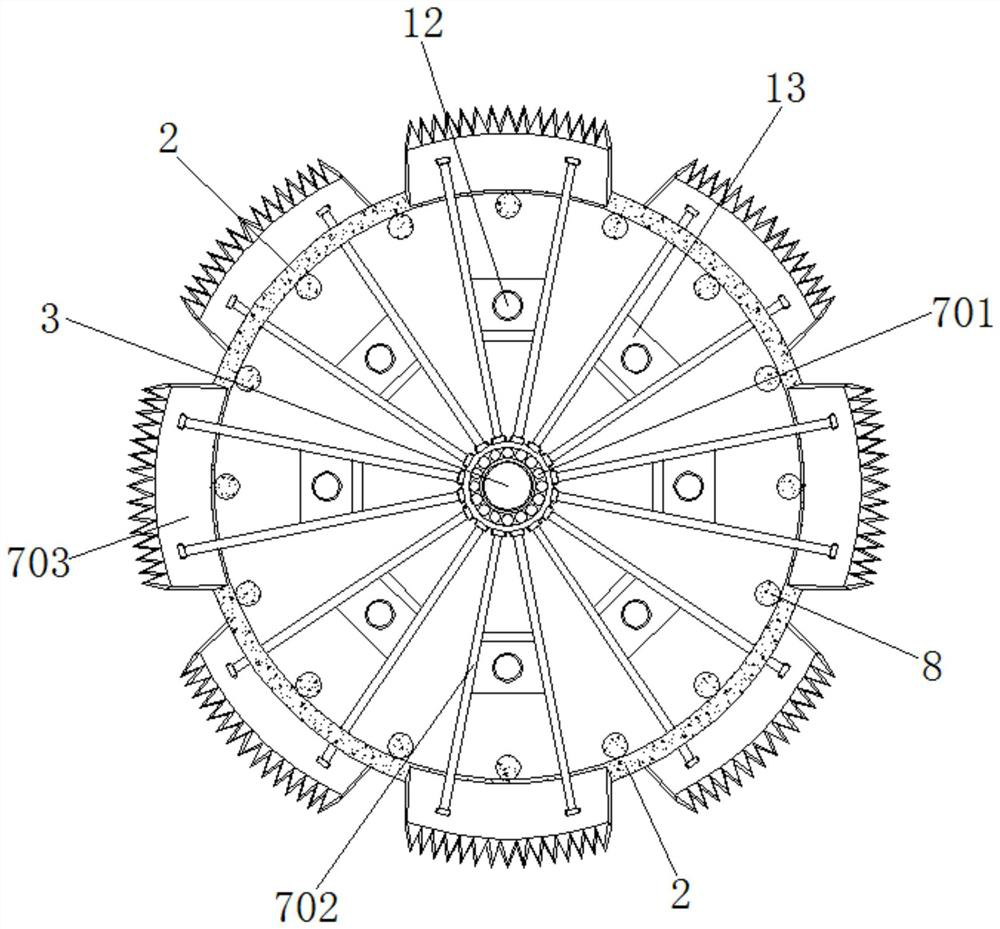

[0056] Example 1, as Figure 1-10 As shown, when the main rod 3 is slowly descending, through the cooperation of the hinge rod 9, the four groups of insertion rods 6 are forced to be gradually unfolded, until the insertion rods 6 are vertically positioned in the holes like the straight steel bars and the prestressed steel strands 8, Then, the driving motor 20 is controlled to cooperate with the gearbox 21 to drive the main rod 3 to rotate, forcing the drill bit 5 to gradually drill into the inner bottom of the hole. down, and the four sets of insert rods 6 will also be drilled into the inner bottom of the hole together with the drill bit 5, and the circular plate 4 is tightly pressed against the inner bottom of the hole, and then a plurality of auxiliary steel bars 12 are inserted vertically into each set of limit positions. Inside the slot 13, until the bottom end of the auxiliary steel bar 12 touches the inner bottom of the hole, and then extends into the inner bottom of the...

Embodiment 2

[0057] Example 2, as Figure 6-9 As shown, when the second hydraulic cylinder 24 is raised, the U-shaped movable plate 17 is raised together with the first hydraulic cylinder 18, the I-beam 22 and the top plate 19, the second lifting and shrinking rod 23 is stretched, and the top plate 19 When rising, the drive motor 20 and the gearbox 21 also rise together. Since the I-beam 22 supports a group of circular steel bars 2 on the top, when the U-shaped movable plate 17 rises, it will also rise together with the pull-resistant pile steel cage, When the first hydraulic cylinder 18 is shortened, the position of the reinforcement cage of the pullout pile remains unchanged, and the top plate 19 descends together with the drive motor 20 and the gearbox 21 , thereby descending with the main rod 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com