Dismantling method of overpass bridge body

A technology for beams and bridges, which is applied in the field of dismantling beams of upper-span bridges. It can solve the problems of large operational impact, low construction cost, and inability to erect protective scaffolding, so as to reduce waste, reduce demolition costs, and shorten the demolition period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

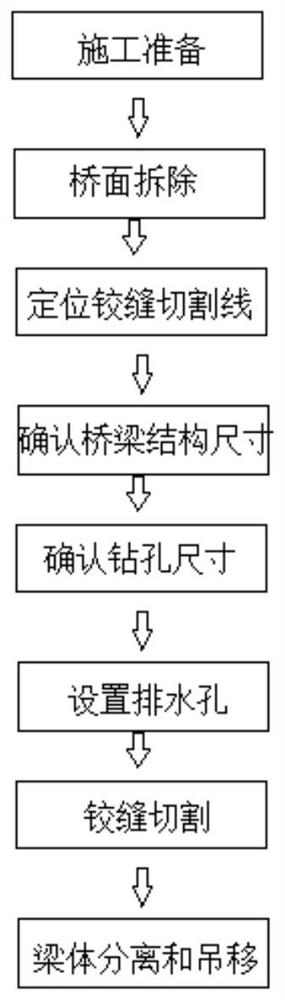

Method used

Image

Examples

Embodiment

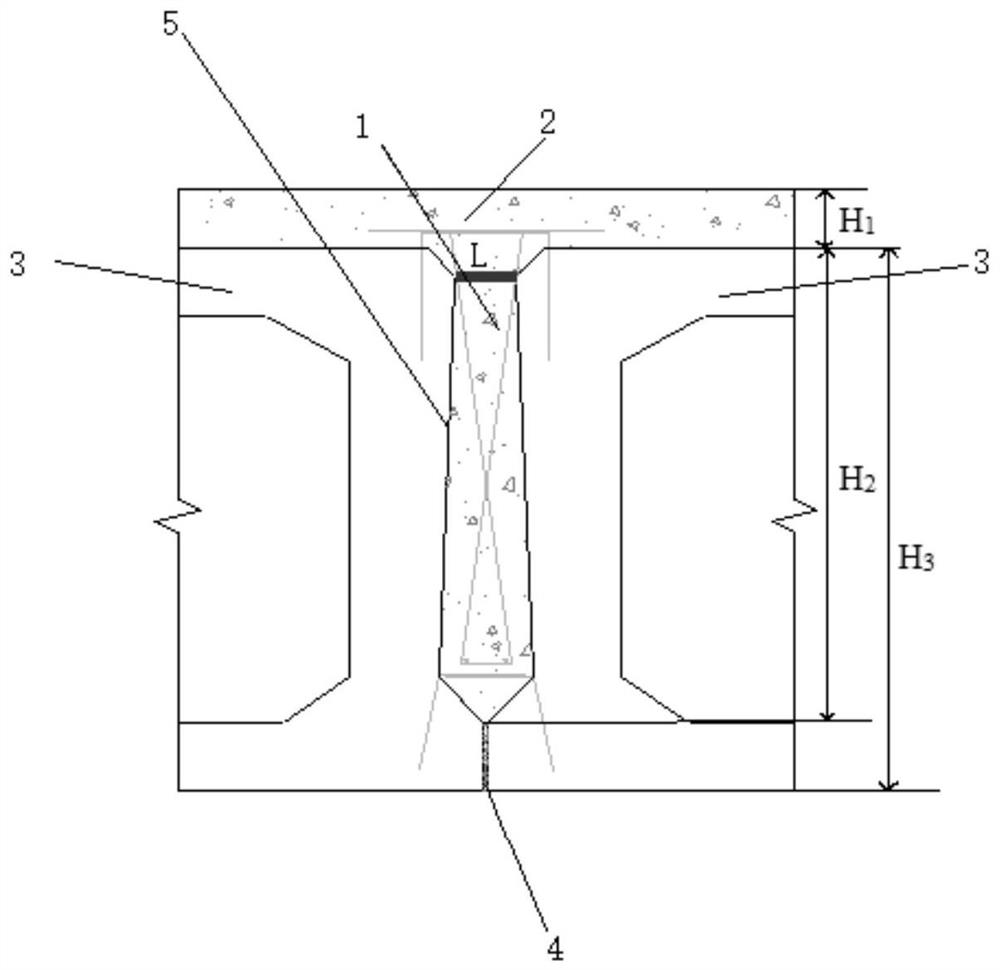

[0036] The dismantling method of the present invention is used to dismantle the Wanjiayuan overpass bridge (1-20m) at the 7th bid section K420+375 of the second line of the Yuhuai Railway from Fuling to Meijiang. The specific construction steps are:

[0037] (1) Construction preparation: Confirm the relative positional relationship between the existing railway equipment and other structures and the flyover; the rated voltage of the existing line catenary line is 25kV, the catenary is about 1.8m away from the bottom of the beam, and the distance between the bearing cable and the bottom of the beam is about 1.8m. 1m; before construction, look for the completion materials of the existing highway bridge, understand the structure of the beam body, use an excavator to excavate the backfill behind the abutments at both ends to the elevation of the bottom of the beam, and then use a hydraulic breaker to chisel the back wall of the abutment , the end of the hollow slab beam leaks out, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com