Fluidized bed reactor for preparing bio-oil from molten salt biomass, reaction system and application of fluidized bed reactor

A fluidized bed reactor and molten salt technology, applied in the field of reaction systems, can solve the problems of high energy loss, low efficiency of pyrolysis and gasification, and large heat loss of particles, so as to reduce heat loss and biomass pyrolysis and gasification High efficiency and high efficiency pyrolysis gasification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

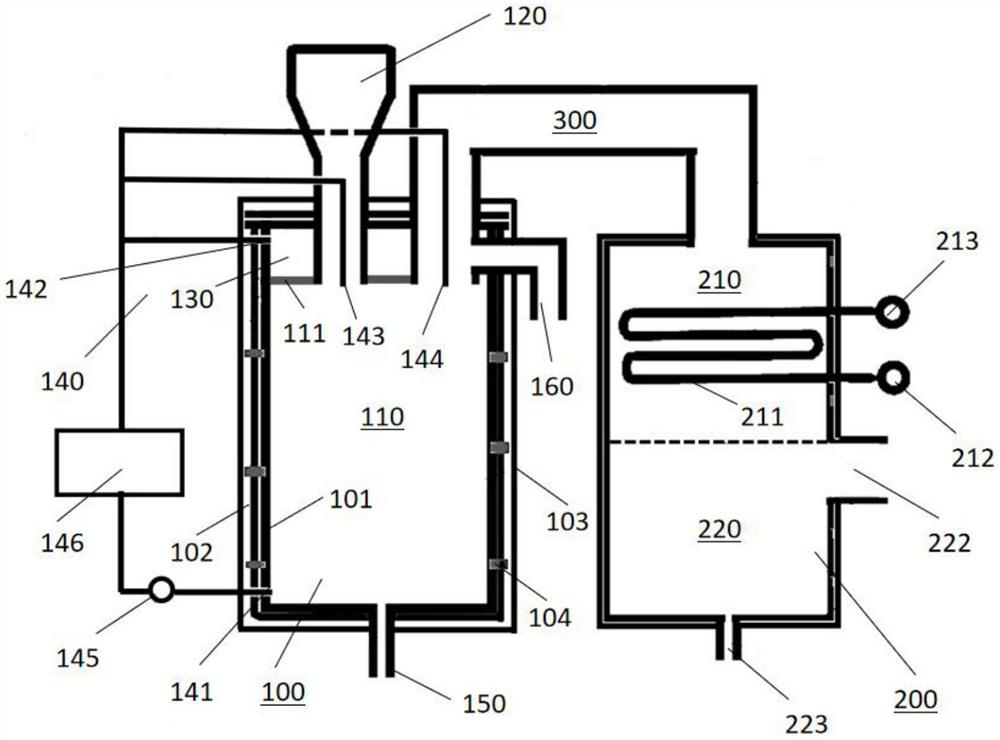

[0035] like figure 1 As shown, Example 1 proposes a fluidized bed reactor for producing bio-oil from molten salt biomass, including a first chamber 100 and a second chamber 200, and the first chamber 100 and the second chamber 200 Communication is through channel structure 300 .

[0036] The first chamber 100 is provided with a reaction chamber 110 , a biomass particle feeding device 120 , a high temperature molten salt chamber 130 , a molten salt circulation device 140 , a first discharge port 150 and a second discharge port 160 .

[0037] Both the biomass particle feeding device 120 and the high-temperature molten salt chamber 130 are communicated with the reaction chamber 110 , and the high-temperature molten salt chamber 130 is arranged on the upper part of the reaction chamber 110 .

[0038] The first discharge port 150 is located at the lower part of the reaction chamber 110 , and the second discharge port 160 is located at the upper part of the reaction chamber 110 . ...

Embodiment 2

[0054] Embodiment 2 proposes to utilize the device of embodiment 1 to carry out the method for preparing bio-oil, comprising the steps:

[0055] (1) Add high temperature molten salt through the high temperature molten salt chamber 130, the first molten salt outlet 142, the second molten salt outlet 143, the third molten salt outlet 144 and the high temperature molten salt through the biomass pellet feeding device 120. The biomass particles in the reaction chamber 110 undergo a pyrolysis reaction in an oxygen-free environment at a temperature of 530° C. to obtain pyrolysis gas and sludge particles, and the sludge particles pass through the first discharge port 150 and the second discharge port 150 respectively. The discharge port 160 is discharged, the pyrolysis gas is passed into the cooling chamber 210, and the reacted molten salt is returned to the high temperature molten salt chamber 130 or the reaction chamber 110 through the molten salt circulation device 140; The high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com