Method for improving strength of foam concrete

A foamed concrete and strength technology, applied in the field of foamed concrete walls, can solve the problems of reducing the effect of coarse aggregate on the strength improvement of foamed concrete, and achieve the effects of saving resources, improving strength, preventing desizing and floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

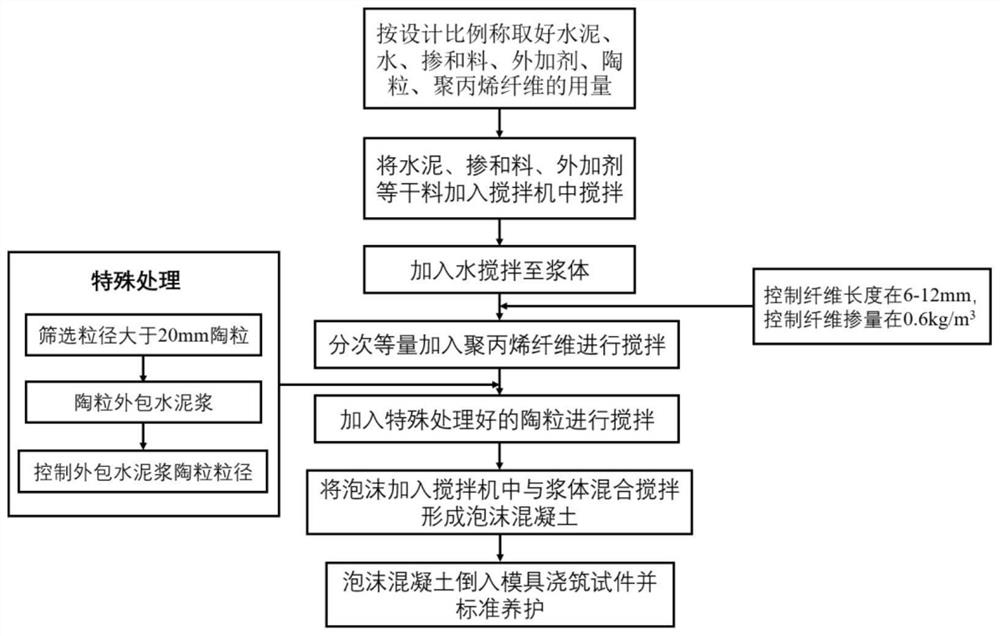

[0023] A method for improving the strength of foamed concrete, comprising the following steps:

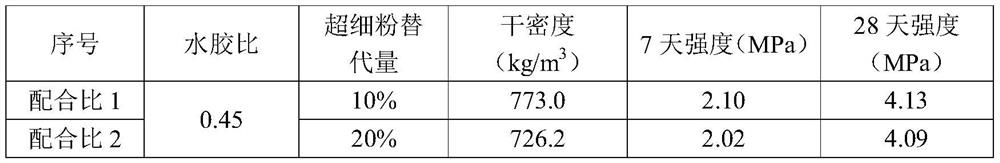

[0024] S1. Weigh the amount of cement, water, superfine powder, fly ash, admixture, ceramsite (coarse aggregate) and polypropylene fiber in proportion, and the ratio of superfine powder to fly ash is 1:1.4 -2.6;

[0025] S2. Take the ceramsite and place it in a sieve with an aperture of 5 mm for screening, and place the ceramsite with a particle size of 5 mm or more in the sieve with an aperture of 15 mm for screening, and finally obtain a particle size within the range of 5-15 mm. ceramsite;

[0026] S3. After fully stirring and mixing cement, fine sand and fly ash, add water and admixture, and stir for 3-5 minutes to form a slurry;

[0027] S4. Divide the screened ceramsite into groups for sizing, soak the ceramsite with water, and stick the fine sand on the surface of the soaked ceramsite, so that the bond between the ceramsite and the cement slurry is tighter. The ceramsite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com