Method for grabbing materials through throwing bucket

A material and grab technology, which is applied in the field of mechanical motion control, can solve the problems that the grab of the door machine cannot be grabbed and is difficult to reach, and achieve the effect of solving the problem of hidden grabbing materials, increasing the safety factor of personnel, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. While exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided so that the present disclosure will be more thoroughly understood, and will fully convey the scope of the present disclosure to those skilled in the art.

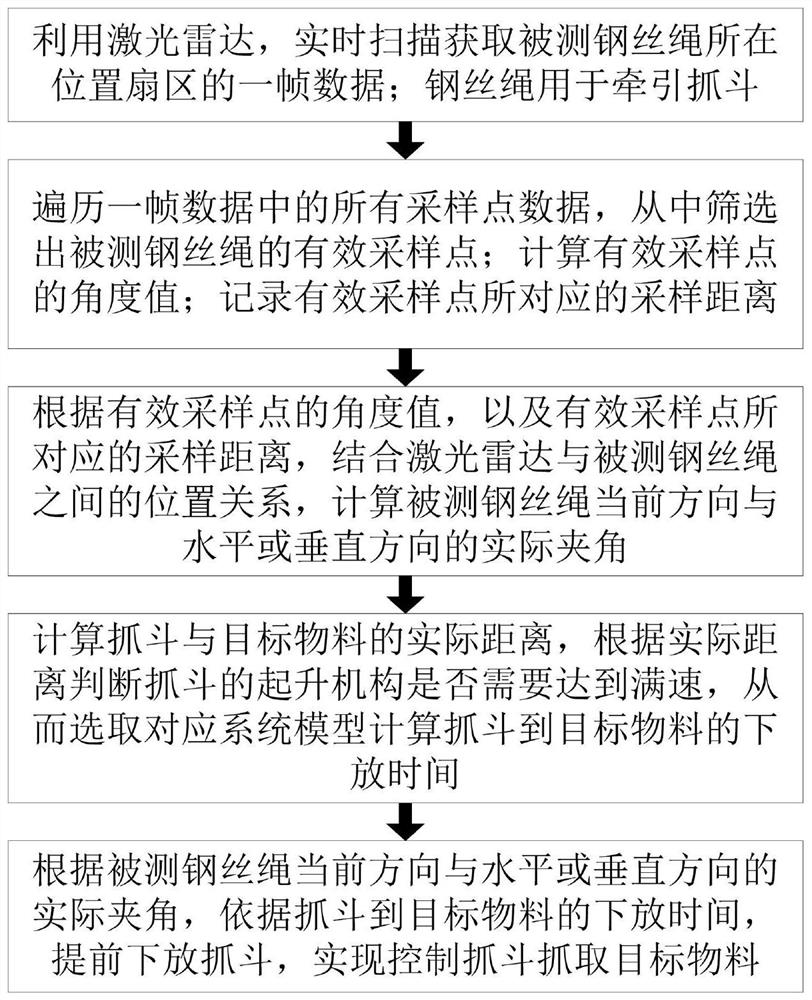

[0063] refer to figure 1 As shown, the embodiment of the present invention provides a method for grabbing materials by a throwing bucket, which specifically includes the following steps:

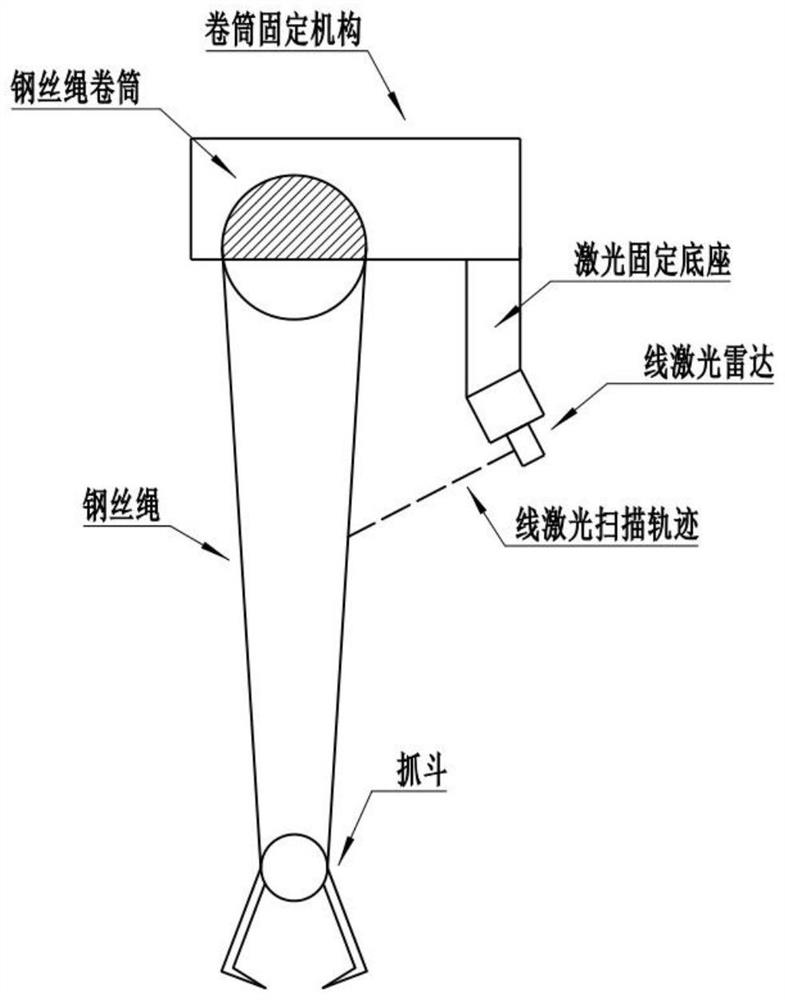

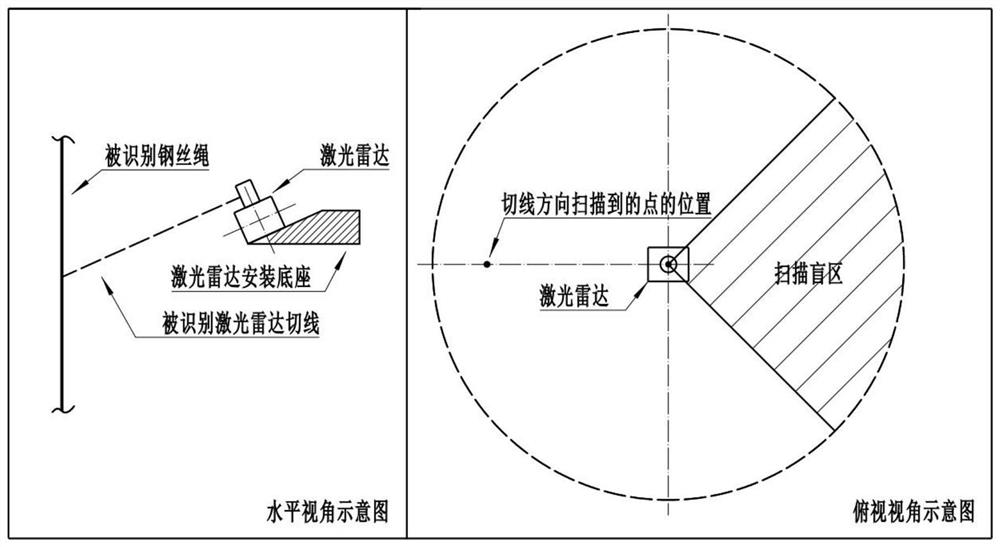

[0064] S1. Use laser radar to scan and obtain a frame of data of the sector where the steel wire rope to be tested is located in real time; the steel wire rope is used for pulling the grab;

[0065] S2, traverse all the sampling point da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com