Sucking and clamping integrated sucker module

A technology of head mold and finger clamp, which is applied in the field of suction clamp integrated head module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

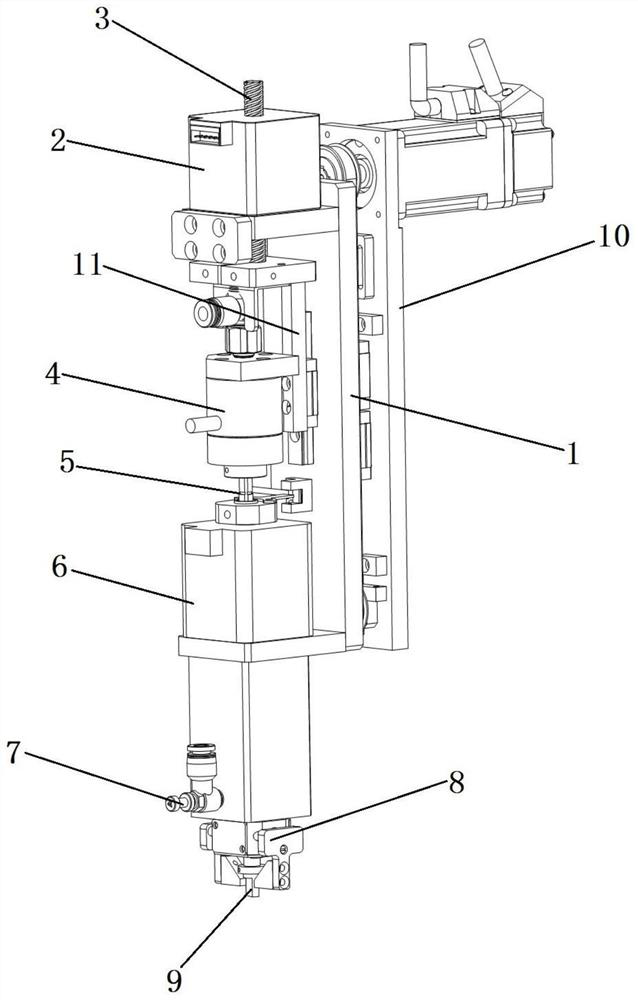

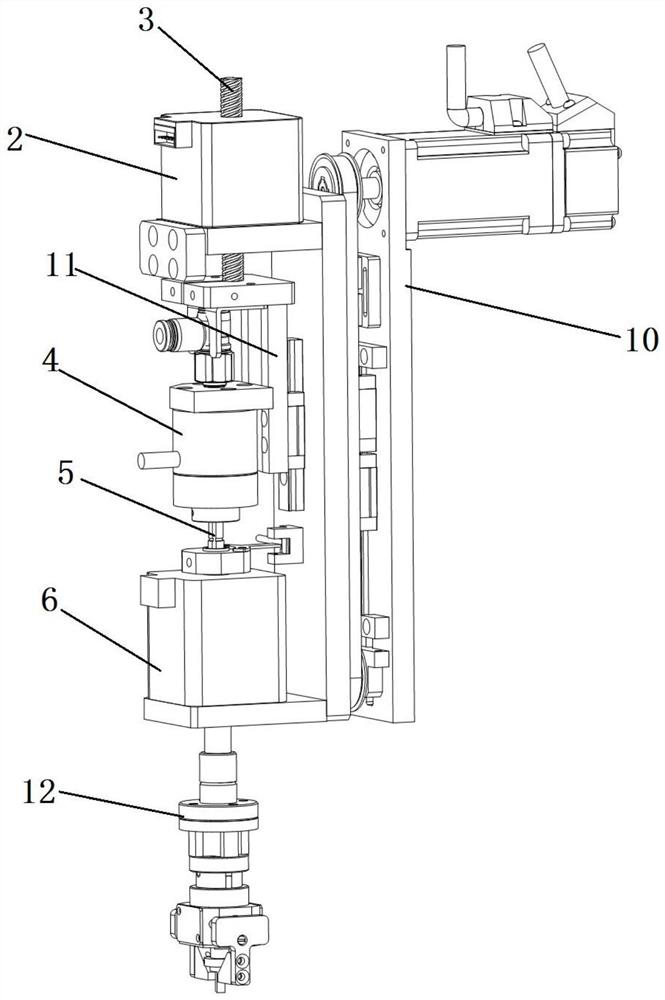

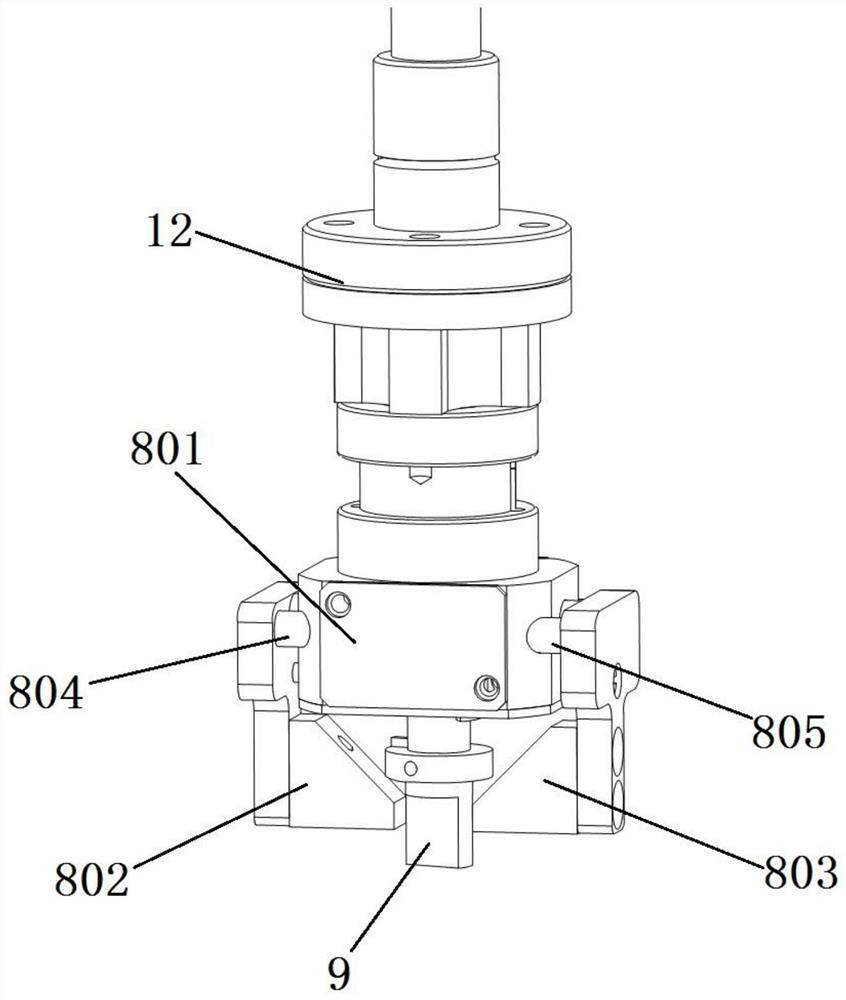

[0037] see figure 1 , a suction clip integrated head-mounting module provided in this embodiment, including:

[0038] Support plate 1 and hollow stepper motor 6;

[0039] A leading screw 3 lifting assembly is installed on the support plate 1, and a sliding plate 11 is connected on the leading screw 3 lifting assembly, and the mounting sliding plate 11 can be lifted and lowered under the driving of the leading screw 3 lifting assembly;

[0040] The installation slide plate 11 is provided with a connecting seat, the connecting seat is connected with a connecting shaft 14 extending downward, and the hollow stepping motor 6 is internally keyed with a rotating shaft 5, and the connecting shaft 14 is connected with the rotating shaft 14. The top of the shaft 5 is rotationally connected, specifically, the connecting shaft 14 is rotationally connected with the rotational shaft 5 through a rotary joint, and the rotational shaft 5 is keyed to a ball spline 12. When the hollow stepper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com