Field angle type manipulator and gas path system thereof

A technology of air circuit system and manipulator, which is applied in the direction of manipulator, storage device, metal processing equipment, etc., can solve the problems of low stamping efficiency, affecting the life of the connecting rod mechanism, affecting the health of human hands, etc., and achieve the effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how to apply technical means to solve technical problems and achieve technical effects in the present application.

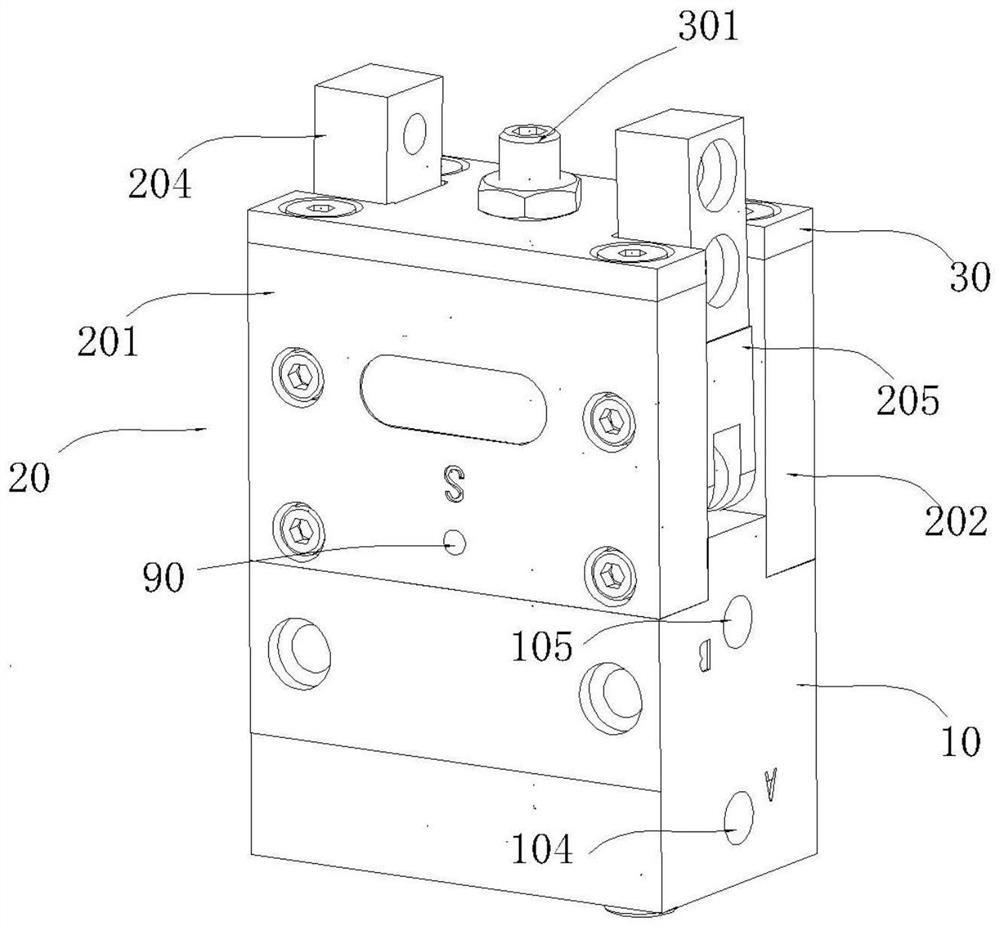

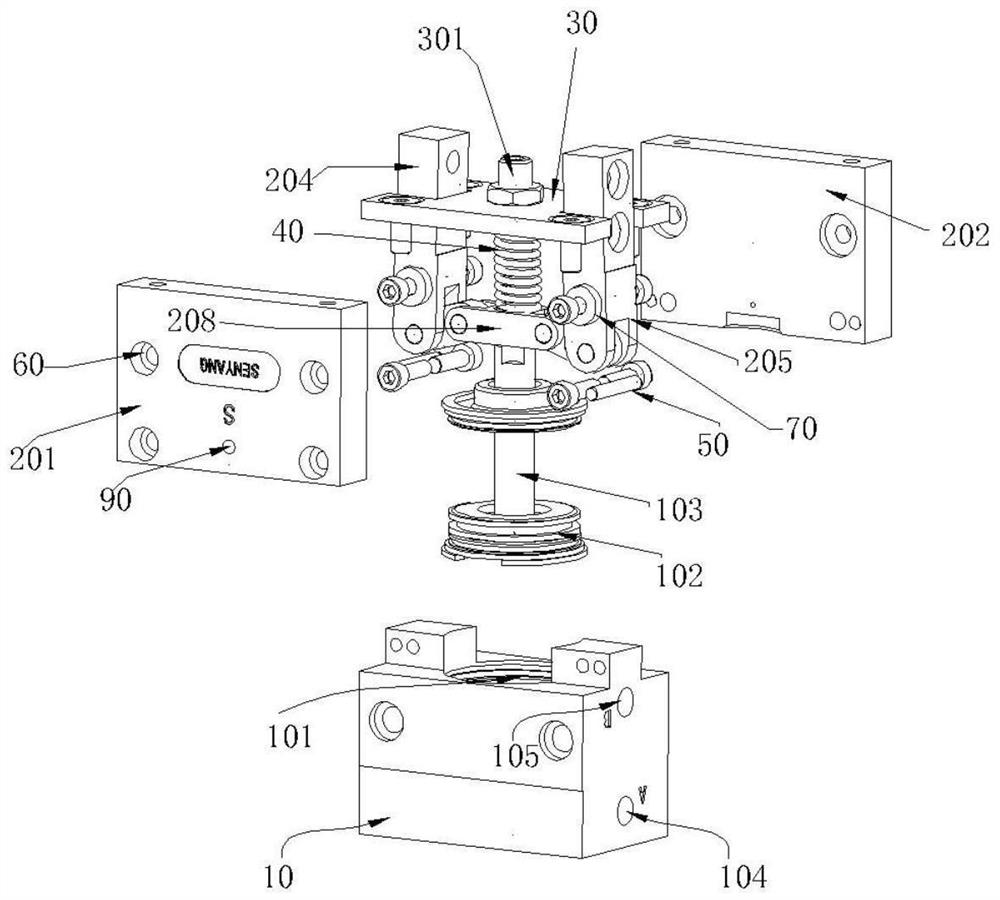

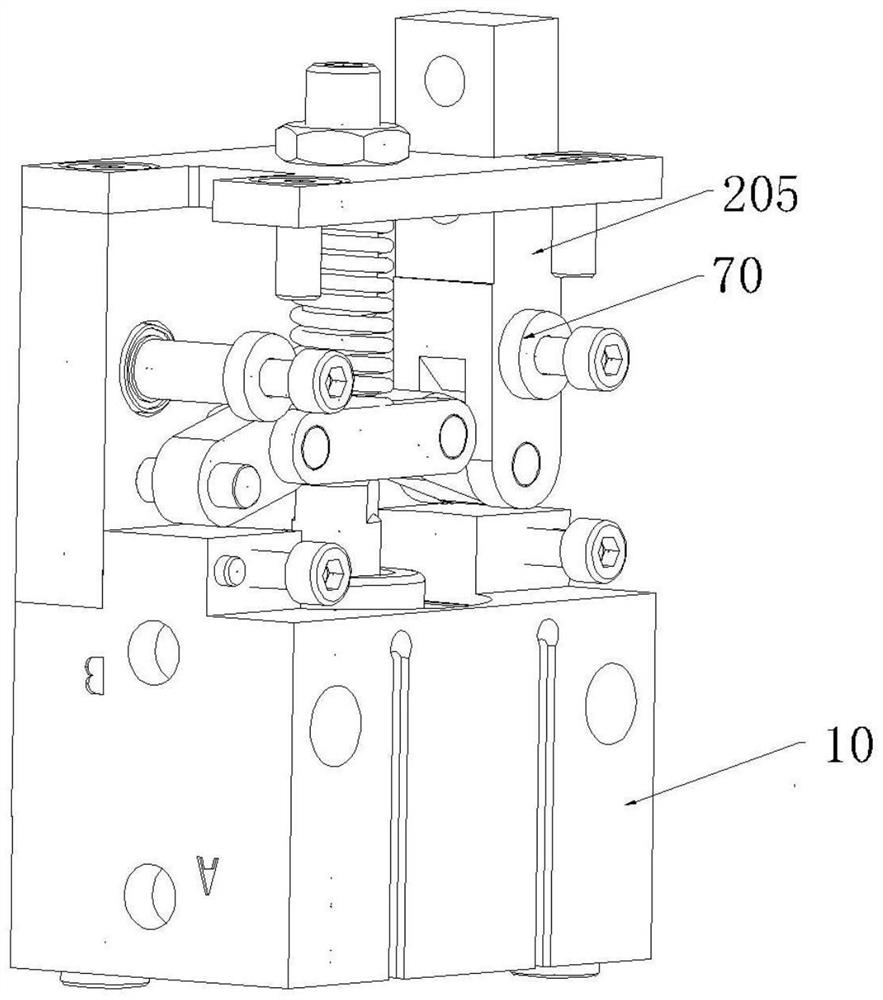

[0025] like Figure 1-6 As shown, an angle-opening manipulator includes a cylinder body 10 and a finger assembly 20, the finger assembly 20 is located on one side of the cylinder body 10, and a movable cavity 101 is formed in the cylinder body 10, and the movable cavity 101 is provided with a piston 102 and a piston rod 103, both sides of the cylinder body 10 are provided with air holes A104 and B105, the air holes B105 are provided near the side of the finger assembly 20, and the air holes A104 and B105 are the same as the air holes B105. The movable cavity 101 communicates with each other. The finger assembly 20 includes a first mounting plate 201 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com